Angular Contact Bearings – A Complete Buyer's Knowledge Guide

Content

- 1 1. What Is an Angular Contact Bearing?

- 2 2. Main Types & Configurations

- 3 3. Important Design Parameters

- 4 4. Core Design Elements

- 5 5. Speed & Precision

- 6 6. Load & Speed Ratings (Key Numbers)

- 7 7. Materials & Cage Options

- 8 Cage (retainer) types – pressed steel, polymer (nylon/PA66), brass, or machined one‑piece designs.

- 9 8. Selection Criteria – What Buyers Should Evaluate

- 10 9. Sealing & Lubrication

- 11 10. Preload & Mounting Arrangements

- 12 11. Typical Applications

- 13 12. Buying Checklist (Specification Sheet)

- 14 13. Ordering & Documentation

- 15 14. Common Standards & Documentation

- 16 15. Installation & Maintenance Tips

- 17 16. Pricing Factors

- 18 17. Ordering Tips

- 19 18. Frequently Asked Questions

- 20 19. Installation & Verification

- 21 20. Maintenance & Life‑Extension

- 22 21. Lubrication Strategies

- 23 22. Common Failure Modes & Troubleshooting

- 24 23. Comparison with Other Bearing Families

- 25 24. Future Trends & Emerging Technologies

1. What Is an Angular Contact Bearing?

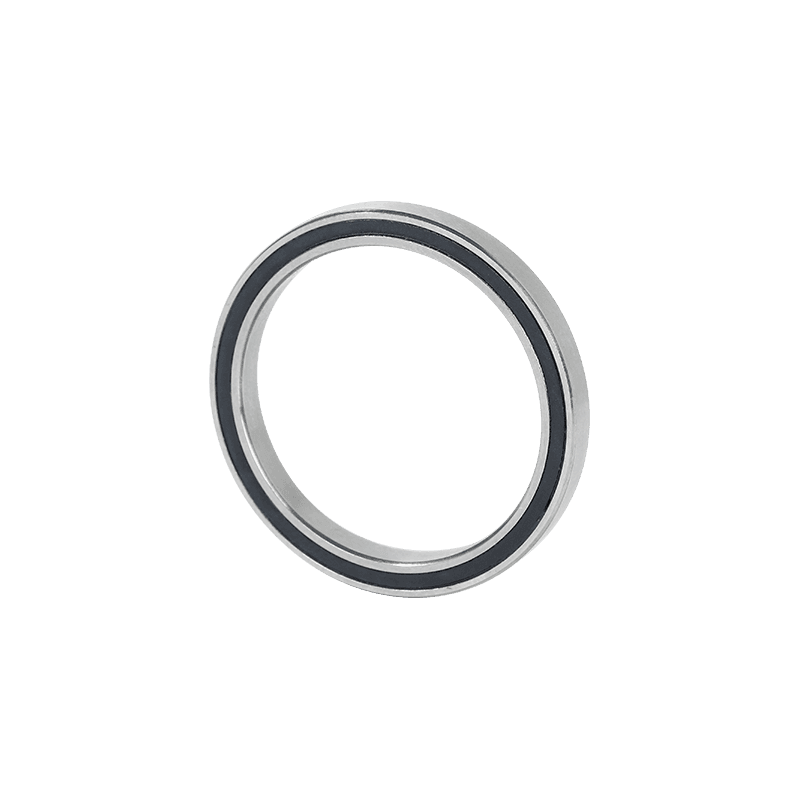

Angular contact ball bearings are a type of rolling‑element bearing in which the inner and outer raceways are positioned at a contact angle (typically 15°–40°) relative to the bearing axis. This geometry enables the bearing to support combined radial‑and‑axial loads or axial loads in one direction, and it allows high‑speed operation when the contact angle is small.

2. Main Types & Configurations

| Type | Typical Use | Key Features |

|---|---|---|

| Single‑row angular contact | High‑speed spindles, pumps | One row of balls; requires a matching bearing (or a second bearing) to balance axial loads |

| Double‑row angular contact | Heavy‑duty gearboxes, compressors | Two rows stacked; higher axial load capacity, can be used alone |

| Four‑point contact (quad‑row) | Ultra‑precision machine tools, aerospace | Four contact points give very high stiffness and load capacity in both directions |

| Matched‑pair (twin) bearings | High‑speed shafts, robotics | Two identical bearings mounted back‑to‑back to share axial load and improve rigidity |

3. Important Design Parameters

| Parameter | Meaning / Influence |

|---|---|

| Contact angle (°) | Larger angles → higher axial load capacity, lower radial load capacity; smaller angles → higher speed capability |

| Series designation | E.g., “C” (15°), “A” (30°), “B” (40°) – suffixes indicate the contact angle |

| Accuracy class | ISO P0‑P6 (or C3‑C6) – determines dimensional and run‑out tolerances; higher class → higher precision, higher price |

| Cage material | Pressed steel, polymer (PA66), brass, bakelite – affects speed, noise, and temperature resistance |

| Load ratings | Dynamic (Cₚ) and static (Cₛ) load capacities, given in kN; essential for life calculation |

| Limiting speed | Maximum permissible rpm, depends on contact angle, cage material, lubrication, and bearing size |

| Dimensions | Standard series (e.g., 7200, 7308) – inner diameter, outer diameter, width; expressed as “d×D×B” |

4. Core Design Elements

●Raceway offset & contact angle – determines load direction capability.

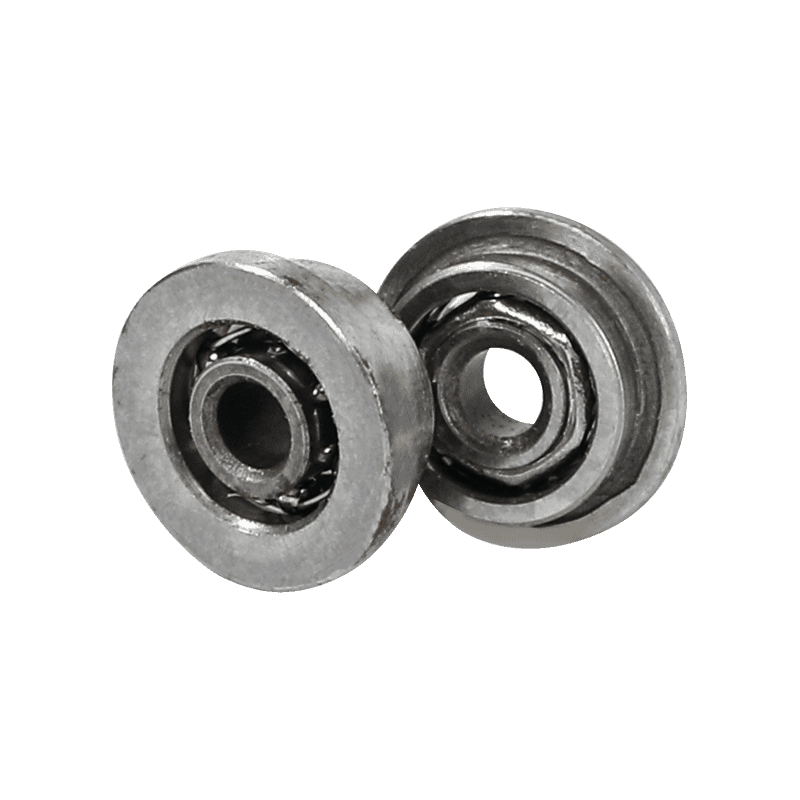

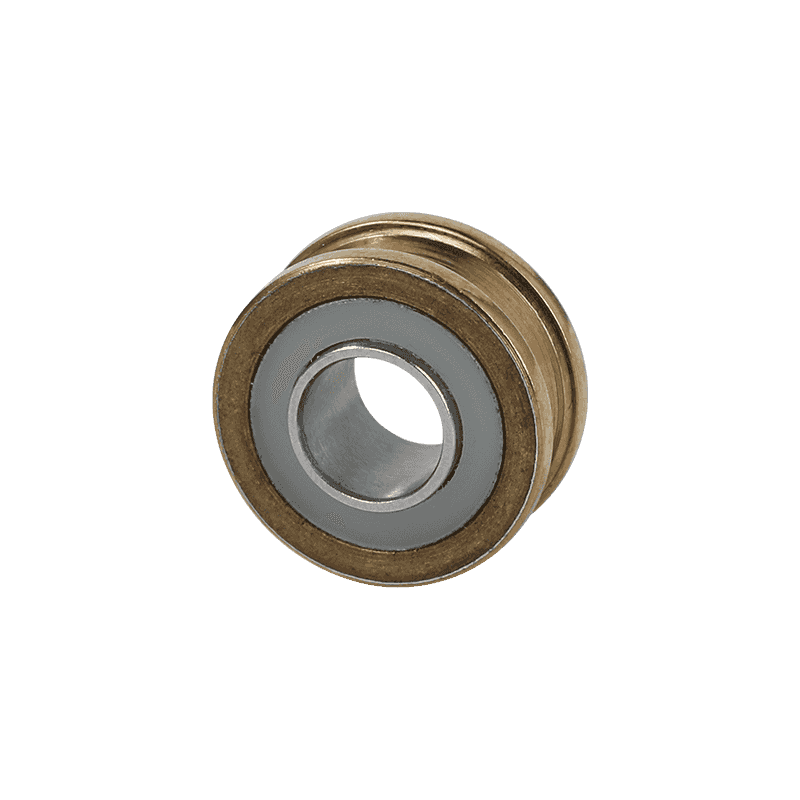

●Cage material – pressed steel, nylon‑filled PA66, brass or bakelite; influences speed limit and noise.

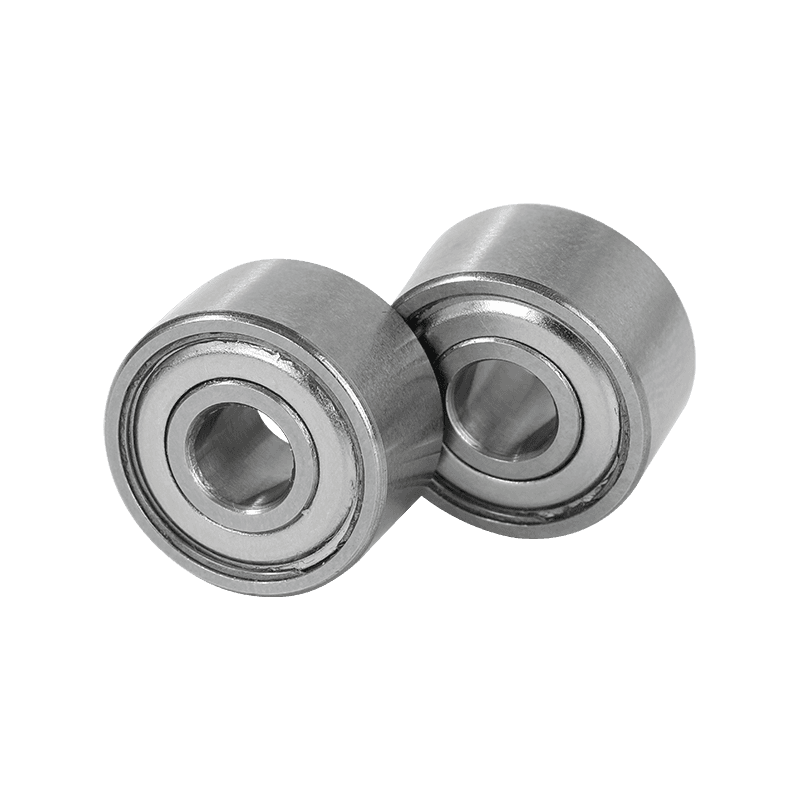

●Ball material – 100 % steel, ceramic (Si₃N₄) or hybrid (steel races + ceramic balls) for higher speed and lower friction.

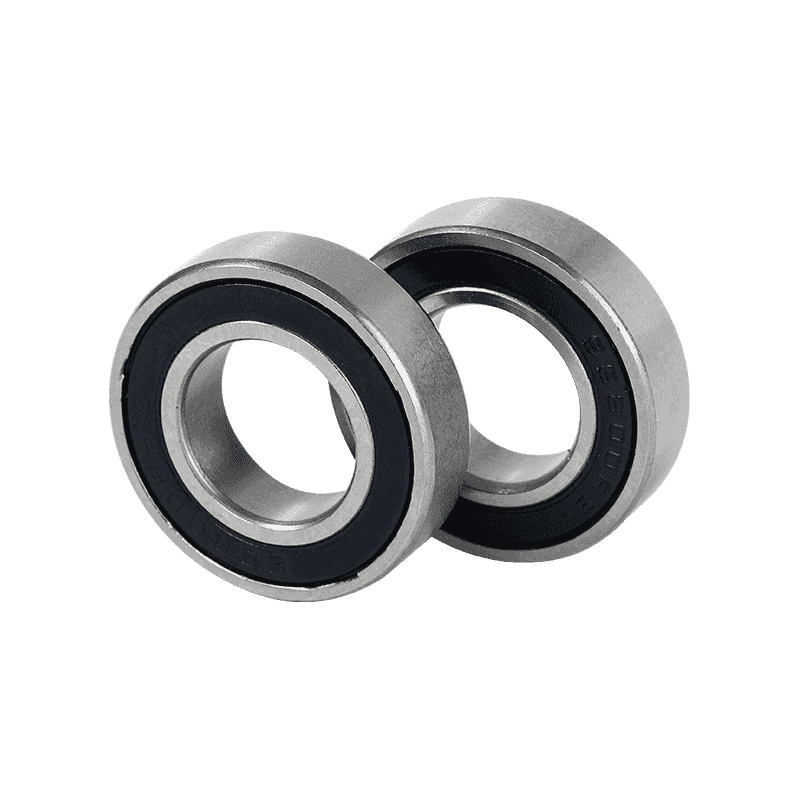

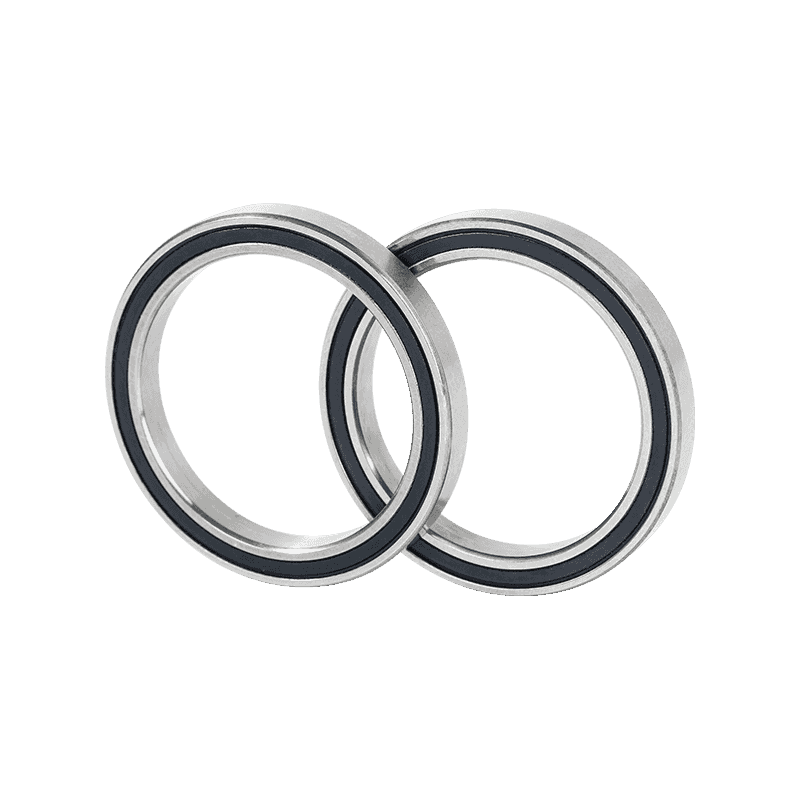

●Sealing options – open, shielded (Z‑type), or sealed (2‑lip) to protect against contamination and retain lubrication.

5. Speed & Precision

●Speed: Angular contact bearings are among the fastest‑rotating ball bearings; typical limiting speeds range from 30 000 rpm to over 100 000 rpm depending on size, contact angle, and lubrication.

●Precision classes:

●ISO tolerance classes P0 – P6 (P6 = highest precision).

●ABEC/ISO standards (ABEC‑1 to ABEC‑9) are also used, especially in the US market.

6. Load & Speed Ratings (Key Numbers)

●Dynamic load rating (C) – the basic load the bearing can sustain for a rated life of 1 million revolutions.

●Static load rating (C₀) – the maximum load the bearing can carry without permanent deformation.

●Speed rating (rpm) – limited by cage material, ball material, and lubrication regime; typical ranges: 20 k‑30 k rpm for steel‑ball, up to 70 k rpm for ceramic‑ball designs.

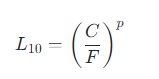

●The ISO 281 formula for basic life is:

where F is the equivalent load and p = 3 for ball bearings.

7. Materials & Cage Options

| Material | Advantages |

|---|---|

| Chrome‑steel rings | Cost‑effective, good wear resistance |

| Ceramic (Si₃N₄) balls | Light weight, high‑speed, low friction |

| Hybrid (steel + ceramic) | Combines strength with low heat |

Cage (retainer) types – pressed steel, polymer (nylon/PA66), brass, or machined one‑piece designs.

8. Selection Criteria – What Buyers Should Evaluate

●Load requirements – radial vs. axial, direction, magnitude. Use the contact‑angle chart (15°, 25°, 30°, 40°) to match axial capacity.

●Speed – high‑speed applications demand low‑mass cages, ceramic balls, and adequate lubrication.

●Temperature & environment – high temperature reduces lubricant life; consider high‑temperature steel or ceramic, and sealed designs for dirty or humid conditions.

●Stiffness & precision – precision classes (ABEC 1‑9, ISO P0‑P6) affect runout; four‑point contact bearings give the highest rigidity.

●Preload & mounting – angular bearings are usually installed in pairs with a defined preload (light, medium, heavy). Proper torque and alignment are critical to avoid premature wear.

●Lubrication – oil‑lubricated, grease‑lubricated, or solid‑film. The ISO 281 life‑adjustment factor κ quantifies lubrication quality.

●Clearance & tolerance – internal clearance (Cₙ) influences heat generation and life; tighter clearance for high‑speed, looser for heavy‑load, low‑speed applications.

●Standards & certifications – ISO 281 (dynamic load & life), GB/T 6391 (Chinese equivalent), DIN ISO 281, and manufacturer‑specific quality marks assure compliance.

9. Sealing & Lubrication

●Seals: Oil‑filled, rubber seals, metal shields, or open designs (for grease lubrication).

●Lubrication: Grease (high‑temperature, EP) for low‑speed or intermittent duty; oil circulation for continuous high‑speed operation. Proper lubrication is critical for life and noise reduction.

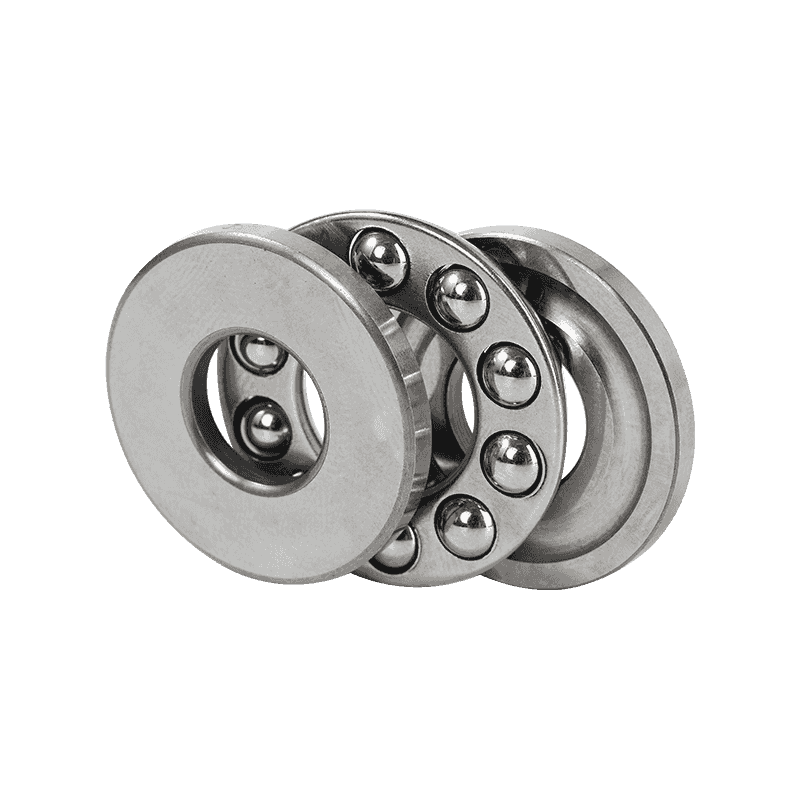

10. Preload & Mounting Arrangements

●Preload: Optional (none, light, heavy) to eliminate clearance, increase rigidity, and improve runout. Preload must be verified after installation (axial displacement measurement or specialized tools).

●Mounting styles:

Back‑to‑back (BTB) – axial loads oppose each other, common for high‑speed spindles.

Face‑to‑face (FTF) – axial loads add, used when higher thrust capacity is needed.

Tandem (in line) – for very high axial loads in one direction.

11. Typical Applications

●Machine‑tool spindles & high‑speed grinding heads – need high stiffness, low runout, and high rpm.

●Pumps & compressors – combined loads from fluid pressure; often use double‑row designs.

●Robotics & precision positioning stages – require matched‑pair bearings for axial balance.

●Aerospace gearboxes & turbine shafts – extreme speed and temperature; ceramic or hybrid balls are common.

●Automotive wheel hubs & transmission shafts – medium speed, high radial load, moderate axial load.

12. Buying Checklist (Specification Sheet)

| Spec Item | What to Ask the Supplier |

|---|---|

| Bore (inner diameter) | Exact mm/in value required for the shaft. |

| Outer diameter & width | Must fit housing clearance; confirm tolerance class (e.g., P0, P5). |

| Contact angle | Choose 15°, 25°, 30°, 40° based on axial load direction. |

| Dynamic load rating (C) | Verify that C ≥ required axial + radial load. |

| Speed rating (rpm) | Ensure rating exceeds maximum operating speed with safety margin. |

| Material | Steel, ceramic, or hybrid – specify based on temperature & speed. |

| Cage type | Steel, nylon‑filled PA66, brass – select for speed & noise. |

| Sealing | Open, shielded, or sealed – match environment (dust, oil). |

| Precision class | ABEC/ISO class needed for runout tolerance. |

| Preload recommendation | Light, medium, heavy – supplier should provide torque values. |

| Lubrication | Grease type, oil viscosity, or solid film; ask for κ factor if available. |

| Standards compliance | ISO 281, GB/T 6391, DIN ISO 281 – request certification copy. |

| Life expectancy (L10h) | Calculated based on load & speed; ask for life‑adjustment factors. |

| Packaging & handling | Ensure protective packaging to avoid contamination before installation. |

13. Ordering & Documentation

| Item | What to Provide | Typical Source |

|---|---|---|

| Series & Size | Bearing number (e.g., 7200‑C‑P6) | Catalog or product sheet |

| Contact Angle | Desired angle (15°, 25°, 30°, 40°) | Suffix “C”, “A”, “B” etc. |

| Accuracy Class | P0‑P6 or C3‑C6 | Manufacturer data sheet |

| Cage Type | Steel, polymer, brass | Catalog description |

| Quantity & Packaging | Units, tube, carton, pallet | Supplier quotation |

| Technical Support | Load & speed calculations, installation guidance | Supplier engineering team (often via online form) |

14. Common Standards & Documentation

●ISO 281 – life rating calculation.

●ISO 492 – static load rating.

●ABMA/ANSI S 1.10 – rating formulas and reliability criteria.

●Manufacturer catalogs (SKF, NSK, FAG, KOYO, PFI, etc.) provide detailed dimension tables, suffix codes (e.g., “A” for 30° contact angle, “C” for 15°, “B” for 40°).

15. Installation & Maintenance Tips

●Pre‑load Matching – For matched‑pair bearings, set the correct preload (light, medium, heavy) to achieve desired stiffness and life.

●Lubrication – Use high‑speed grease or oil as recommended; over‑lubrication can cause heat buildup.

●Temperature Monitoring – Keep operating temperature below the bearing's rated limit (often 120 °C for steel cages, 150 °C for polymer).

●Cleaning – Remove debris before installation; contamination is a leading cause of premature failure.

●Periodic Inspection – Check for noise, vibration, and temperature rise; replace if wear or pitting is observed.

16. Pricing Factors

●Contact angle & row number – Larger angles and double‑row designs increase material usage.

●Accuracy class – Higher precision (P6, C5) commands a premium.

●Cage material – Brass or polymer cages are more expensive than steel.

●Quantity & packaging – Bulk orders and palletized shipments reduce unit cost.

17. Ordering Tips

●Series designation – e.g., “6205‑2RS‑C” where “C” indicates a 15° contact angle.

●Suffixes – indicate cage material (M = machined brass, Y = stamped brass, P = polymer) and precision (P6).

●Match pairs – when ordering a pair, specify the mounting arrangement (BTB, FTF) to ensure correct thrust direction.

18. Frequently Asked Questions

●Can a single‑row bearing handle axial load alone?

Only when paired with a matching bearing or a preload device; otherwise axial load capacity is limited.

●What is the advantage of ceramic balls?

Higher speed capability, lower friction, and better resistance to corrosion, but cost is higher.

●How does the contact angle affect stiffness?

Larger angles increase axial stiffness but reduce radial stiffness; choose based on dominant load direction.

●Do I need a sealed bearing for clean‑room applications?

Yes; sealed bearings prevent particle ingress and maintain lubrication integrity.

●What does “C₀ / P₀ ≥ 8” mean?

It is the ISO 281 fatigue‑limit criterion: static load capacity (C₀) divided by applied static load (P₀) should be ≥ 8 for a fail‑safe design.

| Question | Quick Answer |

|---|---|

| How to choose the contact angle? | Use a larger angle (30°‑40°) for high axial loads; use a smaller angle (15°‑25°) for high speed and lower thrust. |

| Do I need a matched pair? | Single‑row bearings must be paired (BTB or FTF) to balance thrust; double‑row or four‑point contact can operate alone. |

| When is a hybrid bearing worth the extra cost? | For very high speeds (>60 000 rpm), low‑heat, or where weight reduction is critical (e.g., aerospace). |

| What is the difference between P6 and ABEC‑9? | Both denote high precision; P6 follows ISO tolerance, ABEC‑9 follows US standards. Choose based on the supplier’s catalog. |

| Can I replace a damaged angular contact bearing with a deep‑groove ball bearing? | Not advisable; deep‑groove bearings lack the axial load capacity and stiffness of angular contact types. |

19. Installation & Verification

●Clean all components; avoid contamination.

●Handle bearings with gloves or clean tools to prevent damage.

●Mount using proper press tools; ensure concentricity and correct axial positioning.

●Set preload (if required) and verify with axial displacement measurement or a preload gauge.

●Lubricate according to manufacturer's recommendation before operation.

20. Maintenance & Life‑Extension

●Regular inspection – check for abnormal noise, temperature rise, and wear.

●Re‑lubrication – replace grease or oil at intervals defined by operating conditions.

●Seal replacement – seals degrade; replace them during scheduled overhauls.

●Condition monitoring – vibration analysis and temperature sensors can predict impending failures.

21. Lubrication Strategies

| Lubrication Type | Typical Media | Recommended Speed Range | Key Considerations |

|---|---|---|---|

| Grease | Lithium‑complex, polyurea, high‑temperature EP greases | Up to 20 k rpm (depends on cage) | Grease life is limited by temperature; re‑greasing is required only when seals are damaged. |

| Oil‑lubricated (circulating) | Mineral oil, synthetic PAO, high‑viscosity gear oil | 20 k rpm – 70 k rpm for ceramic‑ball spindles | Requires oil pump or splash system; oil temperature must stay below the oil’s degradation point. |

| Solid‑film (e.g., MoS₂, PTFE) | Thin film coatings on races | Low‑speed, high‑temperature (> 200 °C) | Used in aerospace or vacuum environments where liquid lubricants are unsuitable. |

22. Common Failure Modes & Troubleshooting

| Symptom | Likely Cause | Recommended Action |

|---|---|---|

| Elevated temperature (> 80 °C) | Over‑load, insufficient lubrication, contaminated oil | Verify load calculations, check oil temperature, replace oil/grease, inspect seals |

| Vibration spikes | Mis‑alignment, bearing preload too high/low, foreign particles | Re‑measure shaft/runout, adjust preload torque, clean and reinstall with fresh lubricant |

| Noise (whine or grinding) | Cage wear, ball‑raceway pitting, improper cage material for speed | Replace cage (switch to nylon‑filled for high speed), inspect raceway for pitting, consider ceramic balls |

| Seal leakage | Seal damage, excessive pressure, wrong seal type for environment | Replace seal, verify correct seal (2RS vs LLD), ensure proper mounting torque |

| Early fatigue failure | Incorrect contact angle selection, high axial‑to‑radial load ratio, poor material quality | Re‑select bearing with larger α, verify material certification, consider hybrid or ceramic options |

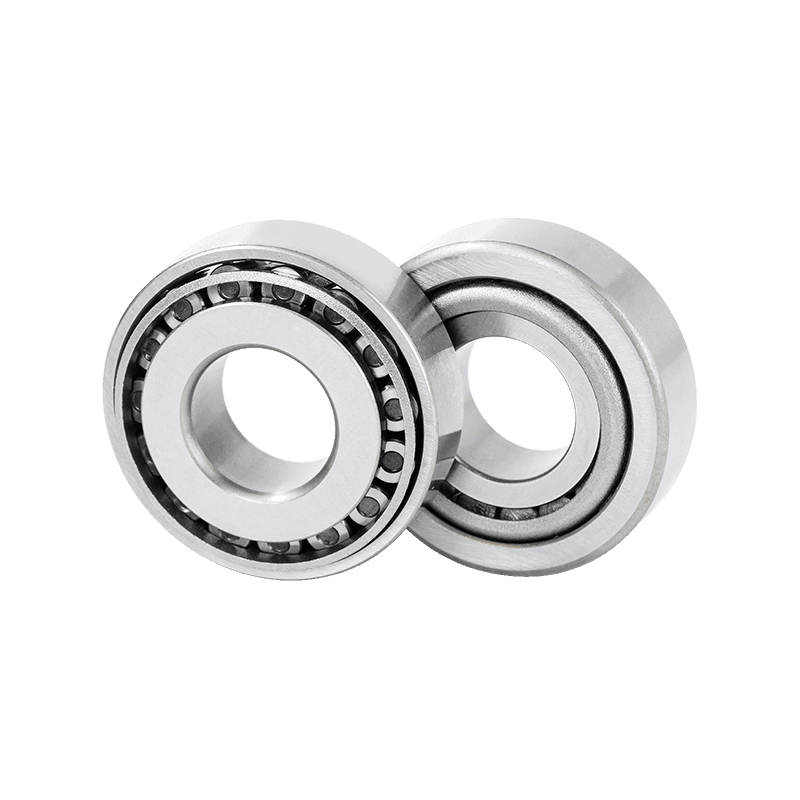

23. Comparison with Other Bearing Families

| Bearing Type | Axial Load Capacity (per direction) | Radial Load Capacity | Typical Speed Limit | Typical Applications |

|---|---|---|---|---|

| Angular‑contact (single row) | Moderate (depends on α) | High | 20 k‑30 k rpm (steel) | Spindles, high‑frequency motors |

| Angular‑contact (double row) | High (bidirectional) | Very high | 15 k‑25 k rpm | Pumps, compressors, gearboxes |

| Four‑point contact | High in both directions | Moderate | 10 k‑15 k rpm | Oil‑free compressors, high‑precision tables |

| Deep‑groove ball | Low (≈ 10 % of radial) | High | Up to 70 k rpm (steel) | General machinery, electric motors |

| Tapered roller | Very high axial (both) | High | 5 k‑12 k rpm | Automotive differentials, heavy gearboxes |

| Cylindrical roller | Low axial | Very high radial | 5 k‑12 k rpm | Heavy radial loads, conveyors |

24. Future Trends & Emerging Technologies

●Hybrid Ceramic‑Steel Designs – Growing adoption in ultra‑high‑speed spindles (≥ 80 k rpm) for semiconductor manufacturing.

●Additive‑Manufactured Raceways – Enable complex groove geometries that improve load distribution and reduce stress concentrations.

●Smart Bearings with Integrated Sensors – Embedded temperature, vibration, and load sensors feed data to predictive‑maintenance platforms (IoT).

●Advanced Lubricants (Nanofluids, Ionic Liquids) – Offer higher load‑carrying capacity and extended life at elevated temperatures.

●Eco‑friendly Seals – Biodegradable polymer seals that meet stricter environmental regulations while maintaining performance.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch