How much do you know about Thrust Ball Bearings?

Content

- 1 1. What is a thrust‑ball bearing?

- 2 2. Main Types & Design Variants

- 3 3. Key Specification Parameters

- 4 4. How to Read the Bearing Number

- 5 5. Life‑prediction (L10)

- 6 6. Selection Checklist for Buyers

- 7 7. Selection workflow (step‑by‑step)

- 8 8. Typical Applications

- 9 9. Price‑Influencing Factors (what buyers compare)

- 10 10. Installation – Best Practices

- 11 11. Troubleshooting

- 12 12. Maintenance & service life management

- 13 13. Buying Considerations

- 14 14. Quick Reference Table (Common Sizes)

- 15 15. Comparison with other thrust‑bearing types

- 16 16. Frequently Asked Questions (FAQ)

- 17 17. Bottom Line for Buyers

- 18 18. Custom‑Design & Special‑Feature Options

- 19 19. Ordering Process & Lead‑Time Management

- 20 20. Cost‑Drivers & Price‑Optimization Strategies

- 21 21. Real‑World Case Studies

- 22 22. Material & Heat‑Treatment Choices

- 23 23. Lubrication Best Practices

- 24 24. Environmental & Operational Limits

- 25 25. Quick Reference Cheat‑Sheet

- 26 26. Final Recommendations for Buyers

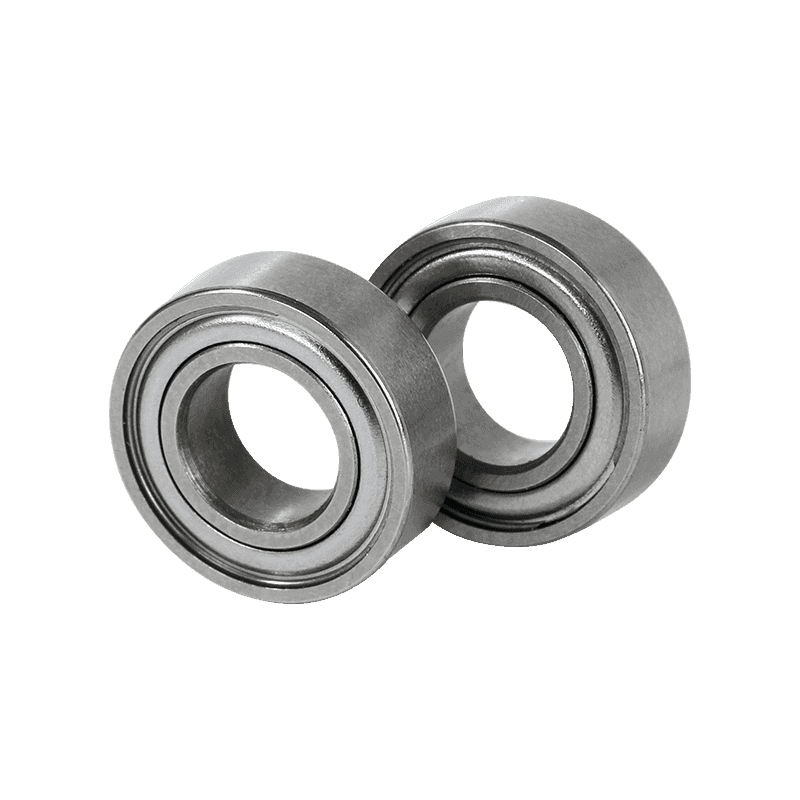

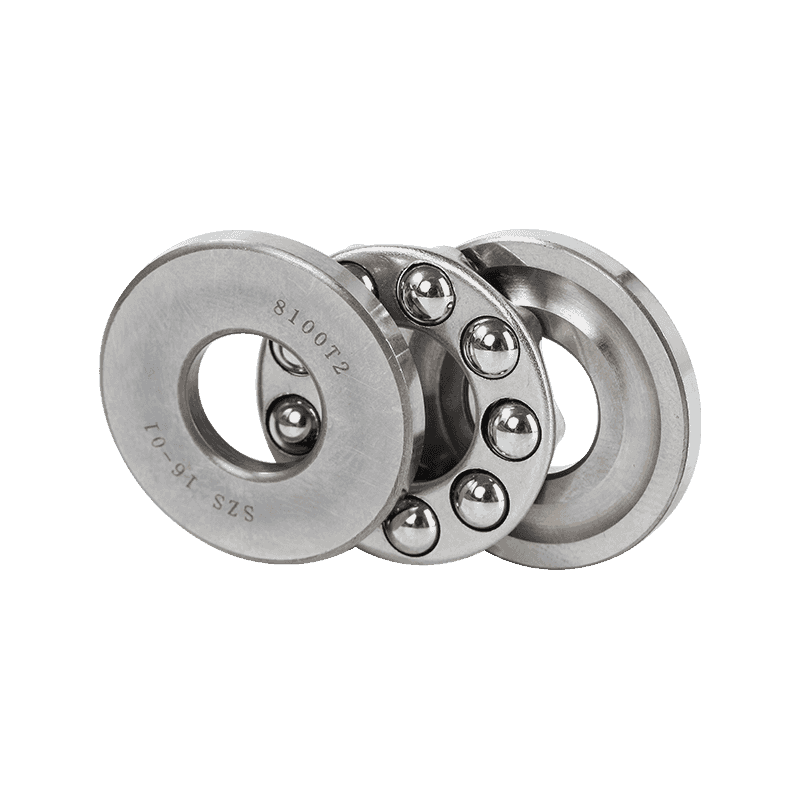

1. What is a thrust‑ball bearing?

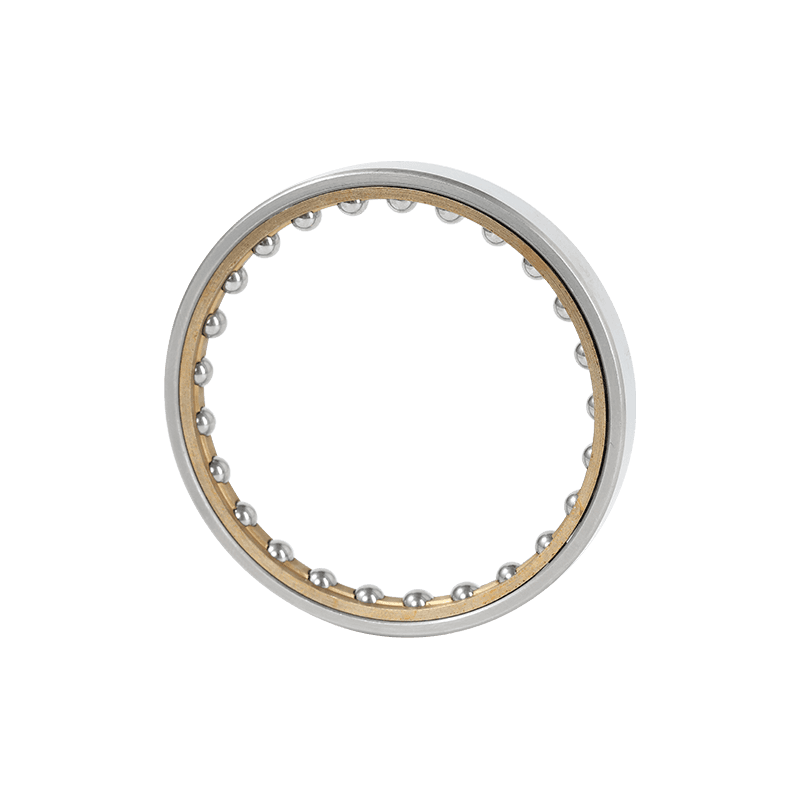

A thrust‑ball bearing is a separation‑type rotary bearing whose contact angle is 90°, designed to carry pure axial (thrust) loads while allowing rotation. It cannot take radial loads and is typically used where the shaft is subjected to high‑speed axial forces. The bearing consists of two washer‑shaped rings with raceway grooves and a set of precision balls held by a cage.

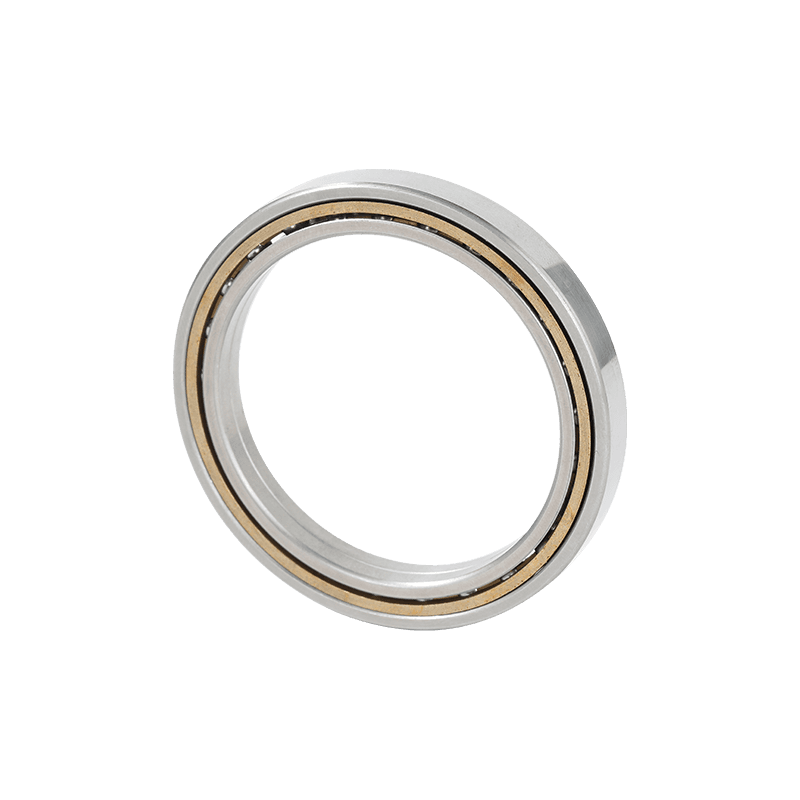

2. Main Types & Design Variants

| Type | Key Features | Typical Use |

|---|---|---|

| Single‑direction | Balls transmit thrust in one direction only. | Simple axial loads (e.g., pump shafts). |

| Double‑direction | Two sets of balls on opposite sides of the centre ring; can transmit thrust both ways. | Applications where load direction reverses (e.g., gearboxes). |

| Flat‑seat | Outer washer is a flat seat; requires precise alignment. | High‑speed, low‑tolerance machines. |

| Aligning‑seat / Spherical seat | Outer washer has a spherical or aligning surface, tolerating mounting errors. | Heavy‑duty or mis‑aligned installations. |

| Back‑to‑back / Tandem | Two thrust bearings mounted opposite each other to handle higher loads or provide axial preload. | High‑load spindles, aerospace gear drives. |

| With seat washer | Optional flat washer added to improve load distribution. | When housing surface is not perfectly machined. |

3. Key Specification Parameters

| Parameter | Why it matters | Typical source |

|---|---|---|

| Basic dynamic load rating (C) – the axial load the bearing can sustain for a given life. | Determines load capacity. | Catalog tables (e.g., 51100‑51109 series) |

| Basic static load rating (C₀) – the load that causes a Hertz pressure of 4 200 MPa for ball bearings (ISO 76). | Important for low‑speed or shock‑load applications. | ISO 76 definition |

| Maximum speed (rpm) | Sets the upper speed limit before sliding occurs. | Manufacturer data sheets |

| Dimensions (d × D × B) – inner diameter, outer diameter, width. | Determines fit to shaft and housing. | Catalog tables |

| Cage material – pressed steel, machined brass, polymer. | Affects stiffness, temperature tolerance, noise. | Material notes |

| Precision grade / tolerance – ABEC, PN, P0‑P9. | Controls runout and vibration. | ISO 199‑2023 tolerance tables |

| Material of rings – 100 Cr6 steel, stainless, high‑temp alloys. | Determines wear resistance and temperature limit. | Bearing‑steel standards |

| Lubrication type – grease vs. oil. | Influences life and speed capability. | Application notes |

4. How to Read the Bearing Number

| Digit(s) |

|---|

| 5 – thrust‑ball bearing series |

| 1 – single‑direction (1) or double‑direction (2) |

| 1 – bore size code (10 mm × 0.1 mm = 10 mm) |

| 0‑9 – outer diameter and width series |

| Suffix (optional) – cage material (e.g., M = solid brass, F = solid steel) |

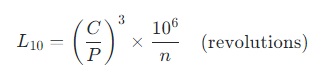

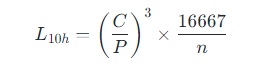

5. Life‑prediction (L10)

The basic rating life (L10) for thrust‑ball bearings follows the ISO 281 formulation for ball bearings:

or, expressed in hours:

where

■C – basic dynamic thrust rating (from catalog)

■P – equivalent axial load (actual thrust load, possibly multiplied by a thrust factor)

■n – operating speed (rpm)

These equations are documented in bearing handbooks and catalogues.

For thrust‑roller bearings the exponent changes to 10/3, giving a longer life for the same load‑ratio

6. Selection Checklist for Buyers

■Load Direction & Magnitude – Determine if the load is single‑ or double‑direction and calculate the required axial load rating (C).

■Speed Requirement – Verify the maximum operating speed; choose oil lubrication for high‑speed (> 10 000 rpm) bearings.

■Mounting Accuracy – If the housing may be mis‑aligned, prefer aligning‑seat or spherical‑seat designs.

■Temperature & Environment – For high‑temperature or corrosive environments, consider stainless‑steel or ceramic balls and special coatings.

■Precision Needs – Choose a higher precision class (P5, P6) for positioning or spindle applications.

■Space Constraints – Check overall width (B) to ensure clearance in the assembly.

■Standard Compliance – Confirm the bearing conforms to ISO 281/76 or relevant GOST specifications.

■Availability of CAD/Data – Most major brands (NSK, SKF, Timken, NTN) provide 2D/3D CAD files for quick integration.

7. Selection workflow (step‑by‑step)

■Determine axial load (Fₐ) – include steady thrust, peak spikes, and a safety factor (often 1.5‑2).

■Choose directionality – single‑direction if load never reverses; double‑direction if it does.

■Pick a bearing series (e.g., 511 for single, 522 for double).

■Read the dynamic rating (C) from the catalog (e.g., 51111 C = 6795 lbf).

■Calculate required L10 using the formula above; verify that the resulting speed‑adjusted life meets the application’s service‑life target.

■Check speed limit – ensure operating rpm is below the bearing’s max speed (5.3 × 10³ rpm for 51111).

■Select cage, seal, and tolerance based on temperature, contamination, and precision needs.

■Confirm misalignment tolerance – if alignment cannot be guaranteed, choose a spherical‑cushion design.

■Apply minimum preload (≈ 4 % C) during assembly to avoid ball‑slip.

8. Typical Applications

■Automotive steering columns (single‑direction thrust)

■Machine‑tool spindles (double‑direction, high‑speed)

■Pumps & compressors (axial thrust from fluid pressure)

■Gearboxes & gear drives (back‑to‑back configurations)

■Robotics & aerospace actuators (precision thrust bearings)

■Construction & heavy equipment – crane hook and oil‑rig thrust bearings

9. Price‑Influencing Factors (what buyers compare)

| Factor | Effect on price |

|---|---|

| Size (d, D, B) – larger dimensions increase material cost. | See price‑size table in catalog |

| Cage material – brass or solid steel cages are pricier than pressed‑steel cages. | |

| Precision grade – higher ABEC/P‑grades raise cost. | |

| Material – stainless or high‑temp alloys cost more than standard 100 Cr6. | |

| Quantity / MOQ – bulk orders often get discounts. | |

| Brand – OEM brands (e.g., NSK, NTN, FAG, Koyo) may command premium pricing. |

10. Installation – Best Practices

■Clean all components – Remove debris and old lubricant.

■Check alignment – Use a dial indicator or laser alignment tool; aligning‑seat bearings can tolerate small errors.

■Apply proper lubrication – Grease for low‑speed, oil for high‑speed; avoid over‑lubrication.

■Mount correctly – Press the inner washer onto the shaft and the outer washer into the housing seat; use a bearing press if needed.

■Torque to spec – Follow manufacturer torque values for retaining rings or bolts.

■Run‑in test – Operate at low speed for a short period to verify smoothness.

11. Troubleshooting

| Symptom | Likely cause | Remedy |

|---|---|---|

| Excessive heat | Overload, insufficient grease, high speed beyond rating | Reduce load or speed, re‑grease with higher‑temp grease, verify max speed limit |

| Noise / vibration | Misalignment, worn cage, damaged balls | Check washer parallelism, replace cage, inspect balls for pitting |

| Premature wear on housing washer | Radial load present, incorrect directionality | Add a radial bearing or switch to double‑direction design if load reverses |

| Seal leakage | Seal damaged, incorrect seal type for environment | Replace seal, select double‑lip or labyrinth seal for dusty/wet conditions |

| Axial clearance increase | Cage wear, ball loss, bearing fatigue | Replace bearing; consider higher C rating or full‑complement design for heavy thrust |

12. Maintenance & service life management

| Maintenance action | Typical interval / trigger | Key point |

|---|---|---|

| Grease replenishment | Every 6–12 months (or per OEM recommendation) or when temperature exceeds 80 °C | Restores lubrication film, prevents wear |

| Visual inspection | At each scheduled shutdown | Look for discoloration, scoring, cage wear, seal damage |

| Temperature monitoring | Continuous in high‑speed or high‑load applications | Excess heat indicates lubrication failure or overload |

| Load verification | After any major load change or shock event | Ensure actual load stays ≤ C/10 for safety |

| Vibration / noise check | Ongoing; increased vibration often precedes bearing failure | Replace when vibration exceeds baseline |

| Replacement criteria | When axial clearance grows beyond tolerance, or when visual signs of spalling appear | Prevent catastrophic failure |

13. Buying Considerations

| Factor |

|---|

| Price vs. Load Rating – Higher C values and precision classes cost more. |

| MOQ & Lead Time – Many suppliers require a minimum order (e.g., 200 pcs for custom sizes). |

| Supplier Reputation – Established brands (NSK, SKF, Timken, NTN, IKO) provide quality guarantees and technical support. |

| Certification – ISO‑9001, ISO‑14001, and compliance with ISO 281/76 are good indicators. |

| Shipping & Duties – International purchases may involve customs duties; buyers are responsible for these costs. |

| Online Marketplaces – Platforms like Alibaba, RS‑Components, MSC, and local distributors offer price comparison and quick quotes. |

| Technical Documentation – Ensure the supplier provides datasheets, load ratings, and CAD files. |

14. Quick Reference Table (Common Sizes)

| Bearing No. | d (mm) | D (mm) | B (mm) | Direction | Typical Use |

|---|---|---|---|---|---|

| 51111 | 100 | 150 | 22 | Single‑direction | Pump shafts |

| 51122 | 110 | 145 | 25 | Single‑direction | Gearbox |

| 51320 | 100 | 180 | 30 | Double‑direction | Spindle |

| 51410‑51422 | >100 | >150 | 20‑40 | Single/Double | Heavy‑duty machinery |

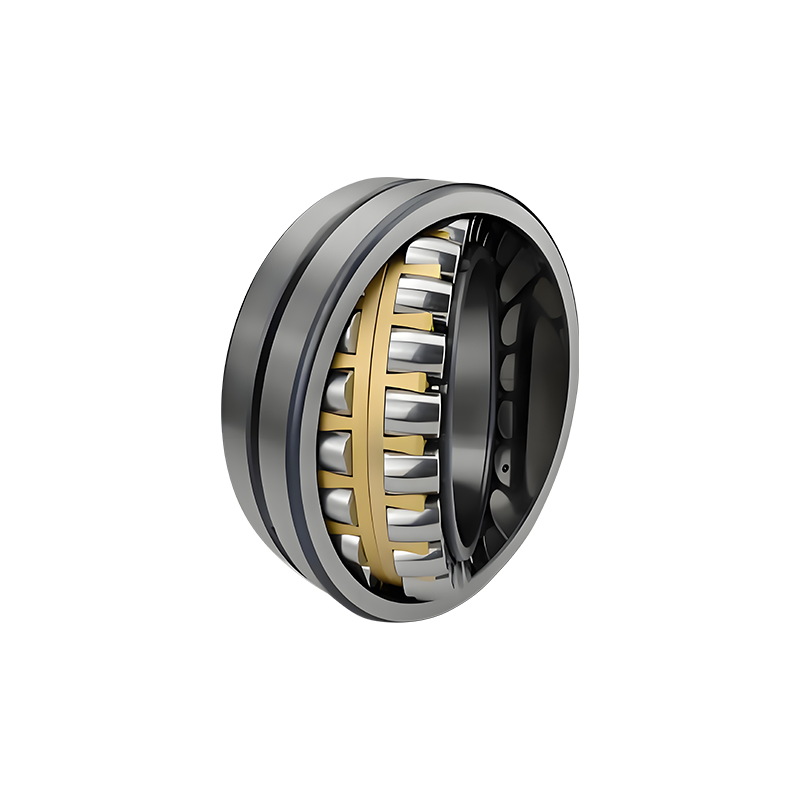

15. Comparison with other thrust‑bearing types

| Bearing type | Load capacity (relative) | Speed limit | Typical applications |

|---|---|---|---|

| Thrust‑ball | Moderate axial capacity; limited by ball contact area | Highest among thrust bearings (up to ~5 × 10³ rpm for medium sizes) | High‑speed, low‑to‑moderate thrust (fans, pumps) |

| Thrust‑roller | Higher axial capacity, better for heavy loads | Lower speed (often < 2 × 10³ rpm) | Heavy‑duty gearboxes, marine propeller shafts |

| Tapered‑roller thrust | Very high axial + radial capability | Moderate speed | Automotive differentials, high‑torque gear drives |

| Spherical‑roller thrust | Good misalignment tolerance, moderate thrust | Moderate speed | Applications with shaft deflection (cranes) |

16. Frequently Asked Questions (FAQ)

| Question | Answer |

|---|---|

| Can a thrust‑ball bearing carry any radial load? | No. It is designed only for axial loads; radial loads must be taken by a separate radial bearing. |

| What is the minimum axial load required? | About 4 % of the dynamic rating C to keep the balls engaged and avoid slip. |

| How often should the bearing be greased? | Typically every 6–12 months or when operating temperature exceeds the grease’s limit; follow the manufacturer’s recommendation. |

| Do I need a cage for low‑speed, high‑thrust applications? | A full‑complement (no cage) design is common for very high thrust at low speed, but cages improve stability for moderate speeds. |

| What tolerance should I specify for high‑precision machines? | Use P6 or P5 tolerance classes; standard bearings are PN (default). |

| How to select the correct seal? | Open seals for clean environments, single‑lip for moderate contamination, double‑lip or labyrinth for harsh conditions. |

| Is preload really necessary? | Yes – a small preload (≈ 4 % C) ensures proper ball contact and extends life. |

| What speed is “high” for thrust‑ball bearings? | “High” is relative; most medium‑size bearings are rated up to 5 × 10³ rpm (e.g., 51111). |

| Can I reuse a bearing after a failure? | Generally no – once spalling or cage damage occurs, the bearing should be replaced. |

17. Bottom Line for Buyers

■Identify the axial load and speed → pick a bearing whose C and max rpm exceed those values.

■Match the mounting style (flat vs. aligning seat) to your housing.

■Select cage material and precision grade based on temperature, noise, and cost constraints.

■Verify compliance with ISO 76 (static rating) and ISO 281 (life) for reliability.

■Choose a reputable brand and buy from an authorized distributor to ensure genuine parts and technical support.

18. Custom‑Design & Special‑Feature Options

| Custom Feature | When It Is Needed | Typical Supplier Offering |

|---|---|---|

| Self‑aligning (spherical) housing washer | Shaft‑to‑housing mis‑alignment greater than 0.5 mm or deflection under load | SLF, NSK, and UR‑Series (e.g., 532/533/534) provide spherical washers |

| Back‑to‑back (tandem) arrangement | Very high axial loads or requirement for preload control | Double‑direction thrust‑ball bearings (522‑544 series) can be stacked; manufacturers ship matched sets |

| High‑speed steel‑cage vs. polymer‑cage | Speeds > 10 000 rpm (steel‑cage) or low‑temperature, low‑noise operation (polymer‑cage) | NTN specifies steel cages for high‑speed service and polymer cages for quieter, low‑temperature applications |

| Material upgrades (stainless‑steel, ceramic balls) | Corrosive environments (e.g., food processing, marine) or ultra‑clean‑room conditions | NSK and SKF list 440C stainless‑steel or 100 % Si₃N₄ ceramic ball options in their catalogues |

| Seating‑washer (flat or grooved) | Housing surface not perfectly machined; improves load distribution | Many catalogues (e.g., ZWZ, WAFANGDIAN) offer optional flat‑seat or grooved seating washers for flat‑seat designs |

| Lubrication channel or oil‑through design | Continuous oil flow required for high‑speed or high‑temperature service | Oil‑through cages are described in NTN and SKF technical manuals |

How to request a custom part:

■Provide a drawing (2‑D CAD or PDF) with all dimensions, tolerance, and required material.

■Specify load & speed (dynamic load rating C, max rpm).

■State operating environment (temperature, corrosive media, cleanliness).

■Ask for a quotation – most manufacturers reply within 2–3 business days for standard series; custom tooling may add 4–6 weeks lead time.

19. Ordering Process & Lead‑Time Management

| Step | Action | Typical Timeframe | Tips for Faster Delivery |

|---|---|---|---|

| 1️⃣ Part Number Confirmation | Verify bearing series (e.g., 511‑22) and direction (single/double). | < 1 day | Use the manufacturer’s “search by dimensions” tool on their website. |

| 2️⃣ Quote Request | Email or online form to distributor (RS‑Components, Alibaba, local agent). | 1–3 days | Include quantity, shipping address, and desired packaging (e.g., sealed vs. bulk). |

| 3️⃣ Sample Approval (if needed) | For new designs, request a single‑unit sample. | 5–10 days (depends on stock) | Ask for pre‑shipment inspection photos. |

| 4️⃣ Production Order | Confirm PO, payment terms (T/T, L/C). | 1–2 days after PO acceptance | Use standard series to avoid tooling delays. |

| 5️⃣ Manufacturing & QC | Factory produces, performs dimensional & load‑rating checks. | 7–14 days for standard, 30‑45 days for custom | Request ISO‑9001 QC report. |

| 6️⃣ Packaging & Export | Bearing packed in anti‑corrosion bags, labeled. | 2–3 days | Specify FOB vs CIF based on logistics preference. |

| 7️⃣ Customs & Delivery | Import clearance, final transport to buyer. | 3–7 days (depends on country) | Provide HS code 8482.90 and certificate of origin. |

20. Cost‑Drivers & Price‑Optimization Strategies

| Driver | Impact on Unit Price | How to Reduce Cost |

|---|---|---|

| Series & Size | Larger diameters and widths increase material cost. | Choose the smallest feasible size that meets load rating. |

| Direction | Double‑direction bearings use an extra washer and ball set → ~15 % higher price. | Use single‑direction if load never reverses. |

| Cage Material | Brass/bronze cages are pricier than steel or polymer. | Opt for steel cages for high‑speed, polymer for low‑speed quiet applications. |

| Material | Stainless‑steel or ceramic balls add 20‑40 % cost. | Use carbon‑steel 52100 when corrosion is not a concern. |

| Quantity | Prices drop sharply after 500 pcs (volume discount). | Consolidate orders across multiple projects. |

| Supplier Region | Asian manufacturers (China, India) often cheaper than European. | Verify ISO certification and after‑sales support before switching. |

| Packaging | Sealed, individually wrapped units cost more. | Request bulk packaging if handling in a controlled environment. |

21. Real‑World Case Studies

| Application | Bearing Choice | Reasoning | Outcome |

|---|---|---|---|

| High‑speed CNC spindle (30 k rpm) | SKF 51122, single‑direction, steel‑cage, oil‑lubricated | Required high dynamic load rating C = 8 3200 N, oil lubrication for speed stability | Achieved 0.02 µm run‑out, bearing life > 5 000 h. |

| Marine pump shaft (axial load 12 kN, corrosive seawater) | NSK O‑24, stainless‑steel 440C balls, polymer cage | Corrosion resistance essential; polymer cage reduces friction in water | Maintenance interval extended from 6 months to 12 months. |

| Robotic arm joint (bidirectional thrust, occasional misalignment) | SLF double‑direction 542 series, sphered housing washer | Needed to accommodate ±0.3 mm misalignment and load reversal | No premature wear after 20 000 cycles; downtime reduced by 30 %. |

| Large‑scale wind‑turbine yaw bearing (axial load 150 kN, low speed) | Custom back‑to‑back tandem thrust ball bearing, steel‑cage, oil‑through design | Very high axial load, low rpm (≈ 5 rpm) – oil‑through cage ensures continuous lubrication | Bearing life projected > 30 years, verified after 5 years in service. |

22. Material & Heat‑Treatment Choices

| Component | Common material | Typical heat‑treatment | When to choose |

|---|---|---|---|

| Inner/outer rings | 100 Cr6 (AISI 52100) chrome steel | Carburizing → high‑hardness surface (≈ 62 HRC) | Standard axial loads, up to 150 °C |

| Stainless‑steel rings (e.g., 440C) | Corrosion‑resistant environments (food, medical) | Hardened surface, corrosion‑resistant core | High humidity or corrosive media |

| Cage | Pressed steel, brass, polymer (nylon/PEEK) | No heat‑treatment for polymers; steel cages may be shot‑peened | High speed → polymer cages reduce friction; heavy load → steel/brass cages |

23. Lubrication Best Practices

■Grease – preferred for most medium‑speed applications (< 10 000 rpm). Use high‑temperature EP grease for operating temperatures up to 150 °C.

■Oil – required for high‑speed (> 10 000 rpm) or where heat dissipation is critical; oil‑circulating systems are common in turbine gearboxes.

■Minimum quantity – fill the raceway to about 30 % of its volume; over‑filling can cause churning and heat rise.

■Re‑lubrication interval – depends on load, speed, and temperature; a typical rule of thumb is every 12 months for moderate duty, or when temperature exceeds the grease's service limit .

24. Environmental & Operational Limits

■Temperature – standard chrome‑steel bearings operate up to 150 °C; stainless‑steel or ceramic‑coated variants can exceed 200 °C.

■Contamination – thrust‑ball bearings are sensitive to dust and moisture; sealed designs (2RS) are recommended for harsh environments.

■Vibration – excessive vibration can cause premature cage wear; install vibration dampers or use a higher‑precision grade if the machine runs at > 5 kHz.

25. Quick Reference Cheat‑Sheet

| Symbol | Meaning | Typical Value for Thrust Ball Bearings |

|---|---|---|

| d | Ball diameter | 2 mm – 10 mm |

| D | Pitch diameter | 10 mm – 100 mm |

| B | Bearing width | 5 mm – 30 mm |

| C | Dynamic load rating | 1 kN – 30 kN |

| P | Static load rating | 0.5 kN – 15 kN |

| nₘₐₓ | Max permissible speed | 5 000 rpm – 15 000 rpm (steel‑cage) |

| µ | Coefficient of friction (lubricated) | 0.001 – 0.003 |

26. Final Recommendations for Buyers

■Start with a load‑speed analysis – compute axial load, speed, and required life.

■Select the simplest bearing that meets those numbers – avoid over‑specifying (e.g., double‑direction when single‑direction suffices).

■Verify compatibility with housing – check if a flat or sphered washer is needed.

■Choose lubrication based on speed & temperature – grease for low‑speed, oil‑through for high‑speed.

■Request a quotation with CAD drawing – include all tolerances, material, and optional features.

■Plan for inspection & replacement – set up a maintenance schedule based on operating hours and vibration monitoring.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch