Are ball bearings better?

Content

There's no absolute "good" or "bad" in ball bearings; it all depends on their application. While they excel in many lightweight, high-speed applications, they also have limitations when handling extremely heavy workloads.

Let's examine their advantages from the following perspectives:

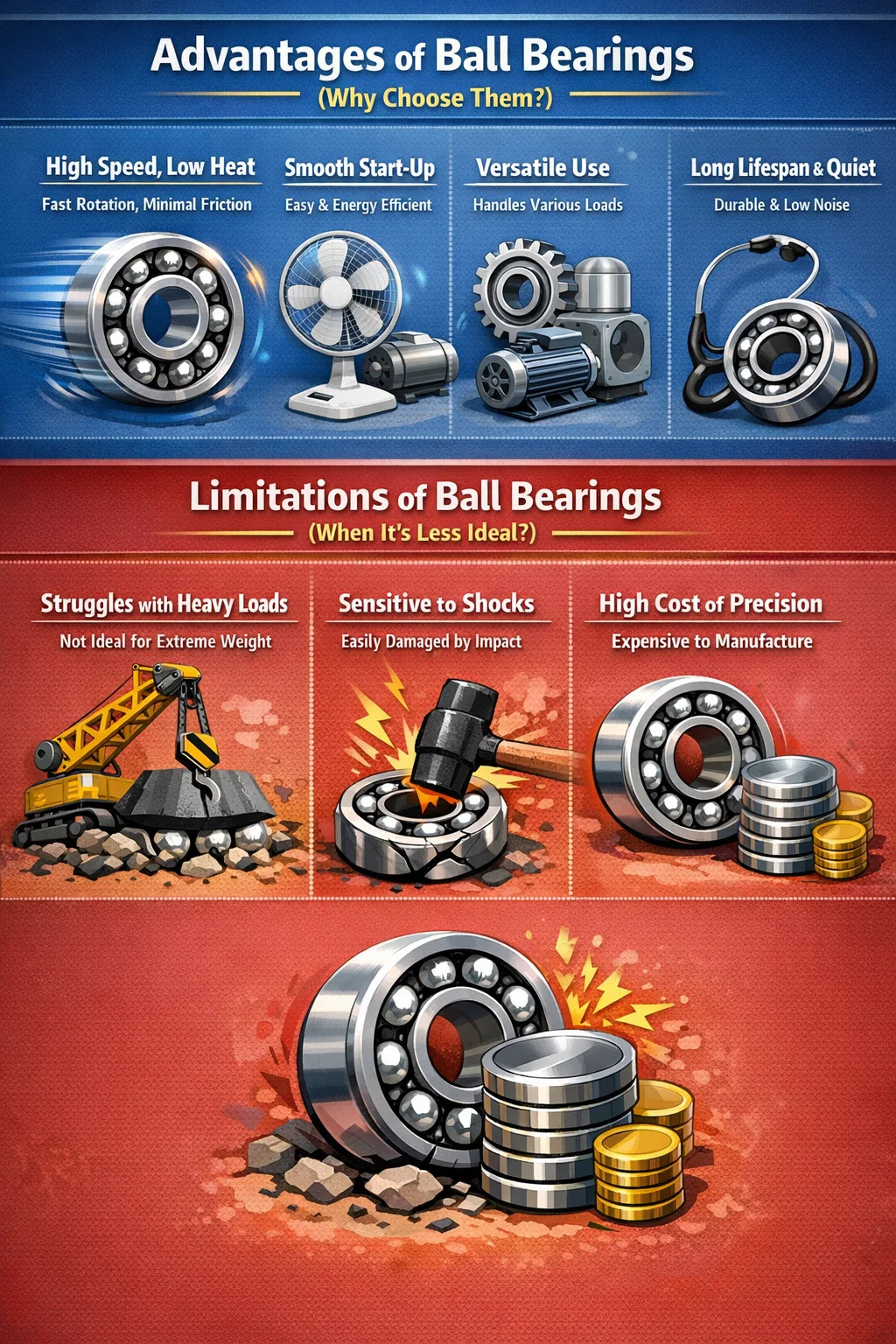

▲ Advantages of Ball Bearings (Why Choose Them?)

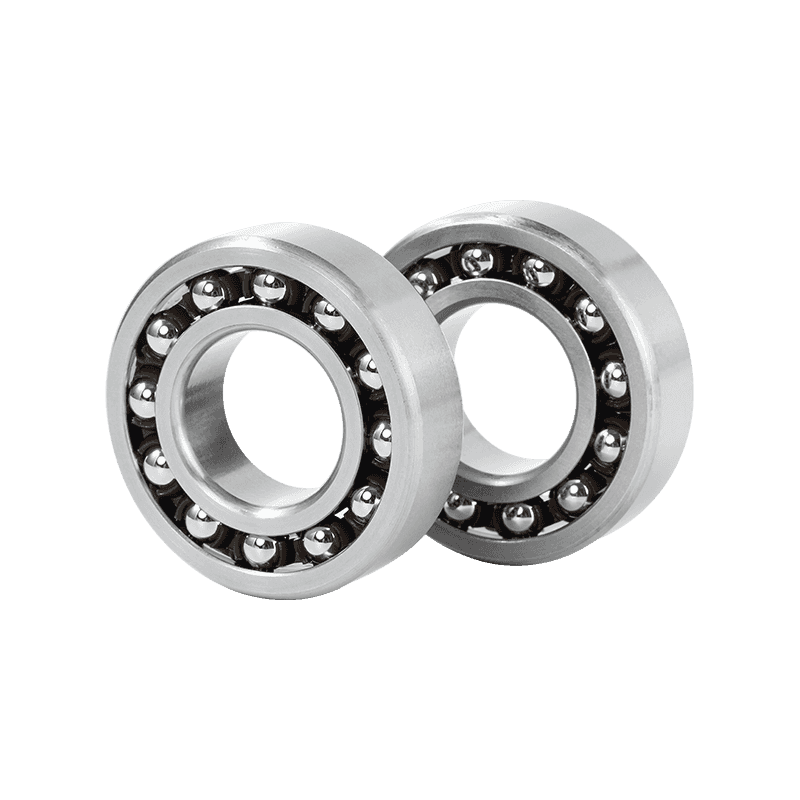

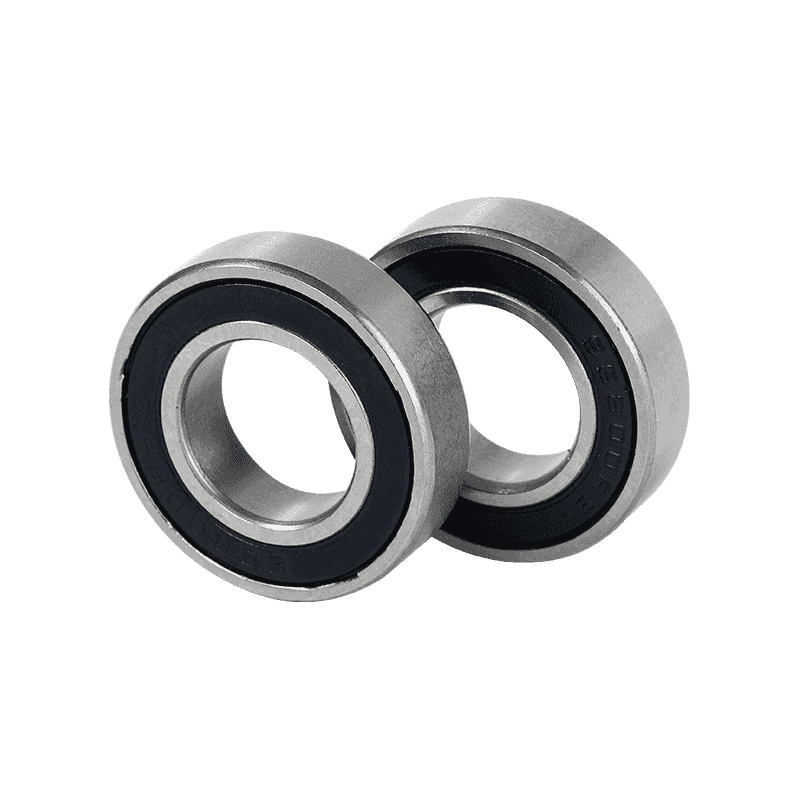

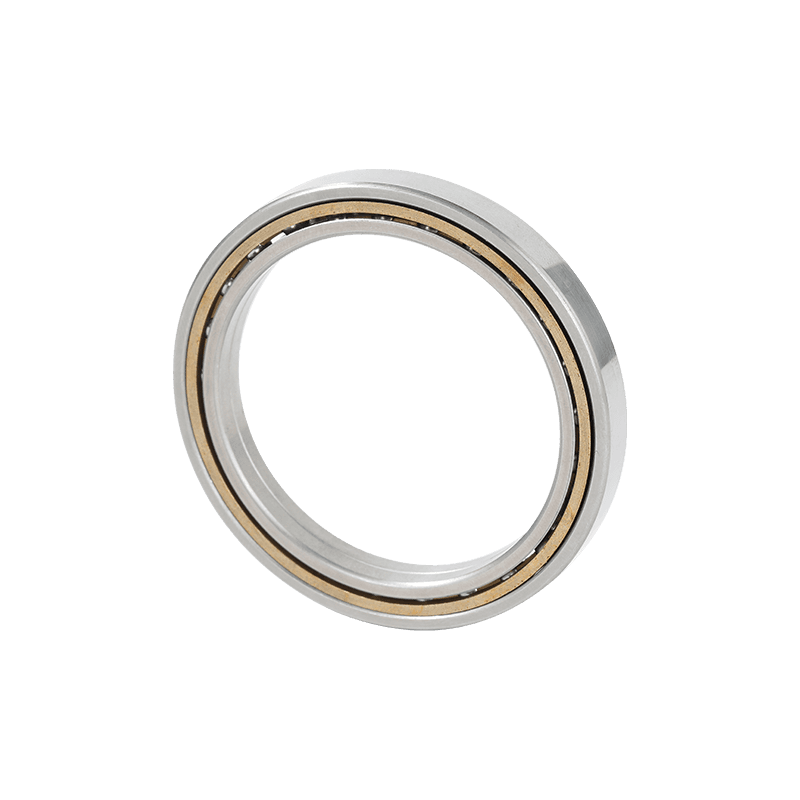

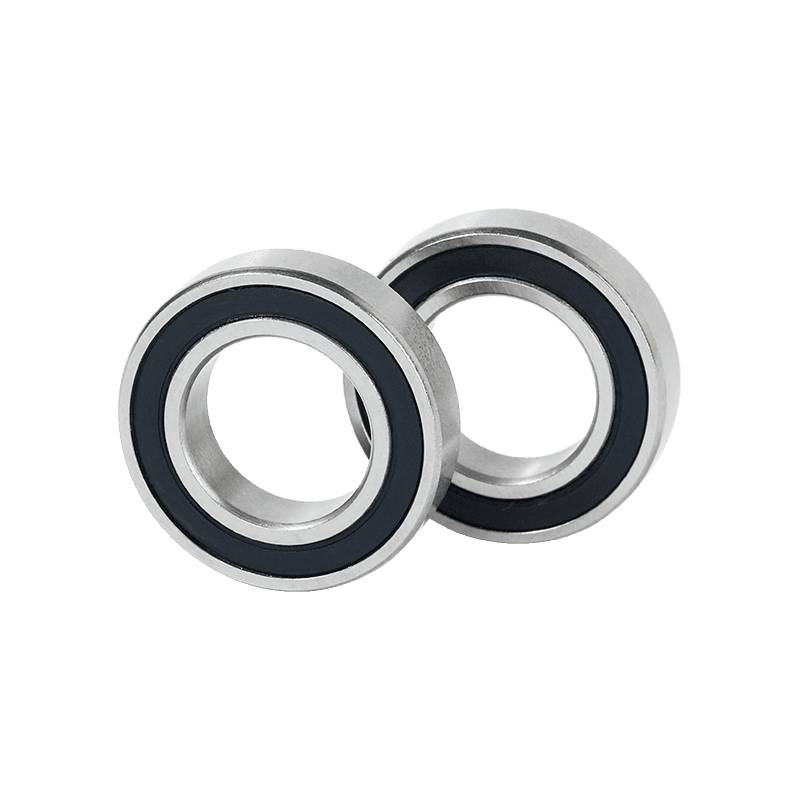

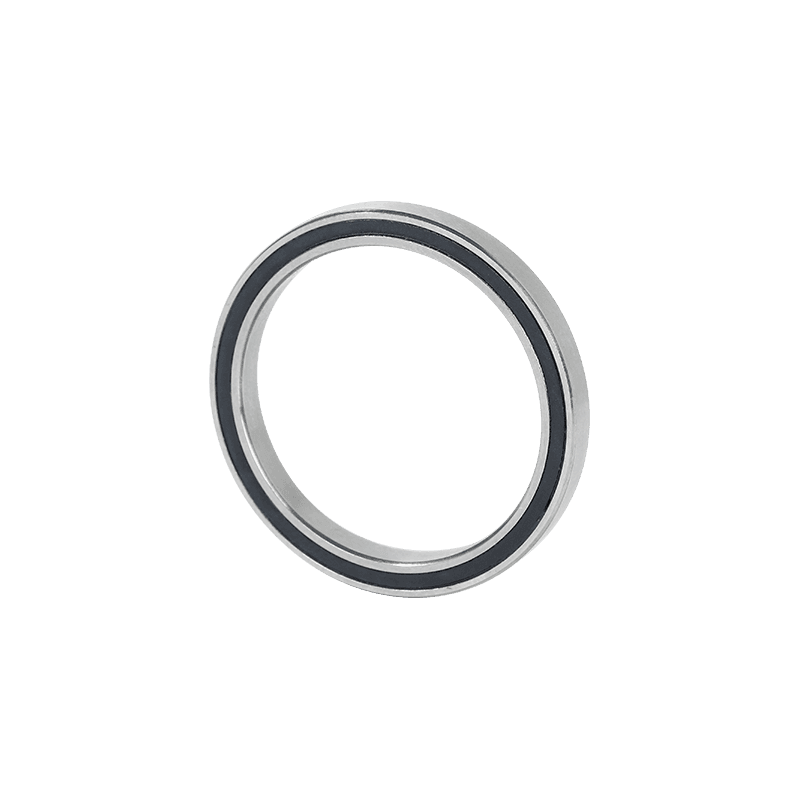

High Speed, Low Heat: Ball bearings excel at high-speed rotation. Because the contact point between the steel ball and the track is minimal, resistance is extremely low. This is similar to running much faster on roller skates than in flat shoes; they generate very little heat during high-speed rotation, resulting in high efficiency.

Smooth Start-up and Energy Saving: Whether in fans or motors, ball bearings make machine startup incredibly easy, without any "sticky" feeling, saving considerable energy.

Versatile: They can withstand not only vertical pressure (such as the force of wheels hitting the ground) but also small amounts of lateral thrust. This versatility makes it very popular in various small appliances and precision instruments.

Long lifespan and quiet operation: With proper maintenance (adequate lubrication), these bearings can run for a long time with a very smooth sound, without the harsh metallic friction noise.

▲ Its limitations (when is it less ideal?)

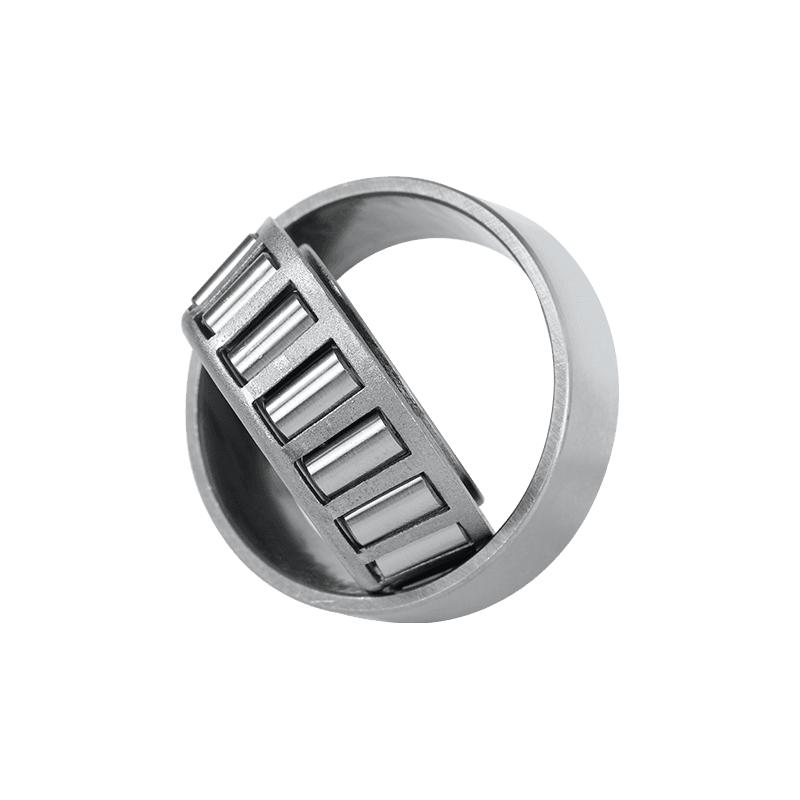

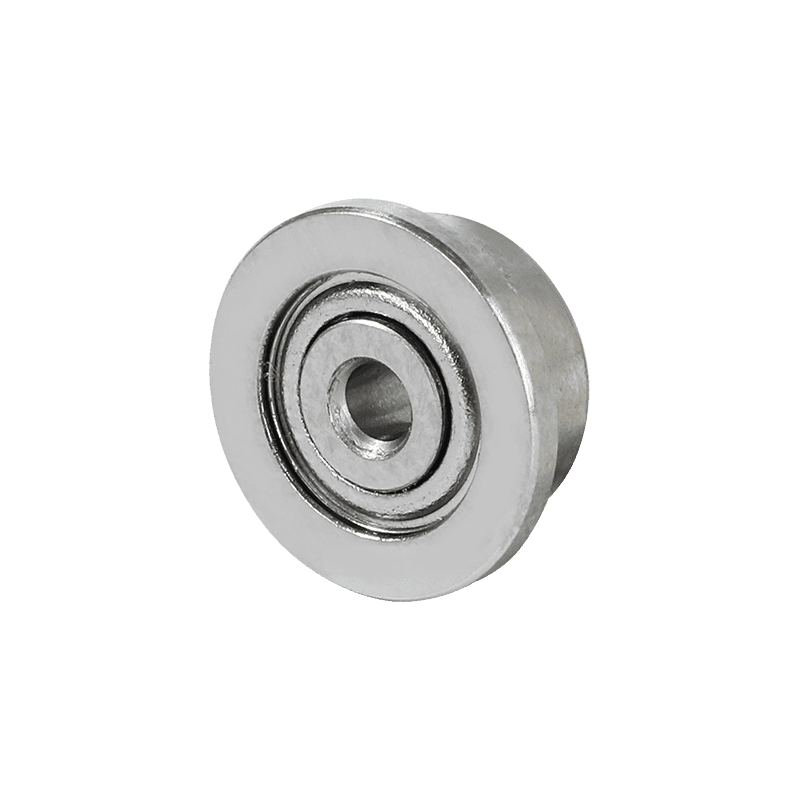

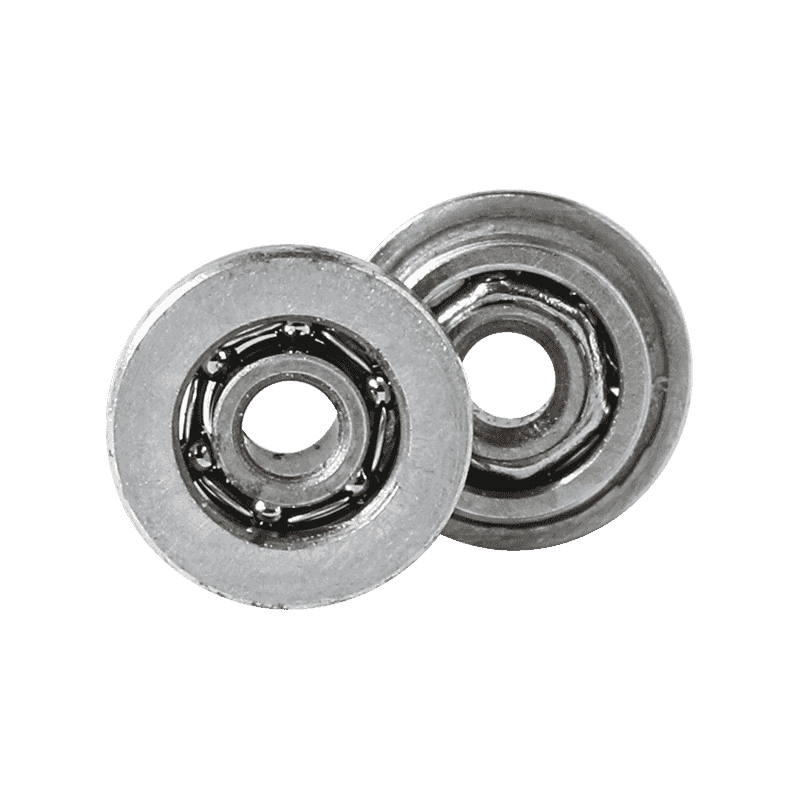

Susceptibility to heavy loads: The Achilles' heel of ball bearings is their vulnerability to excessive weight. Because of their point contact, excessive pressure can cause the balls to dent the tracks. In applications requiring heavy loads, such as cranes and truck axles, roller bearings with larger contact areas are typically chosen.

Susceptibility to shocks: If your equipment frequently experiences severe impacts or vibrations, the small balls inside ball bearings are easily damaged. In such cases, the more robust sliding bearings may be more durable.

Precision means high cost: Manufacturing these precise small balls and smooth tracks is not cheap. Compared to some simple plastic sleeves or simple metal plates, ball bearings are slightly more expensive.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch