How to measure rotary friction of miniature ball bearings?

Content

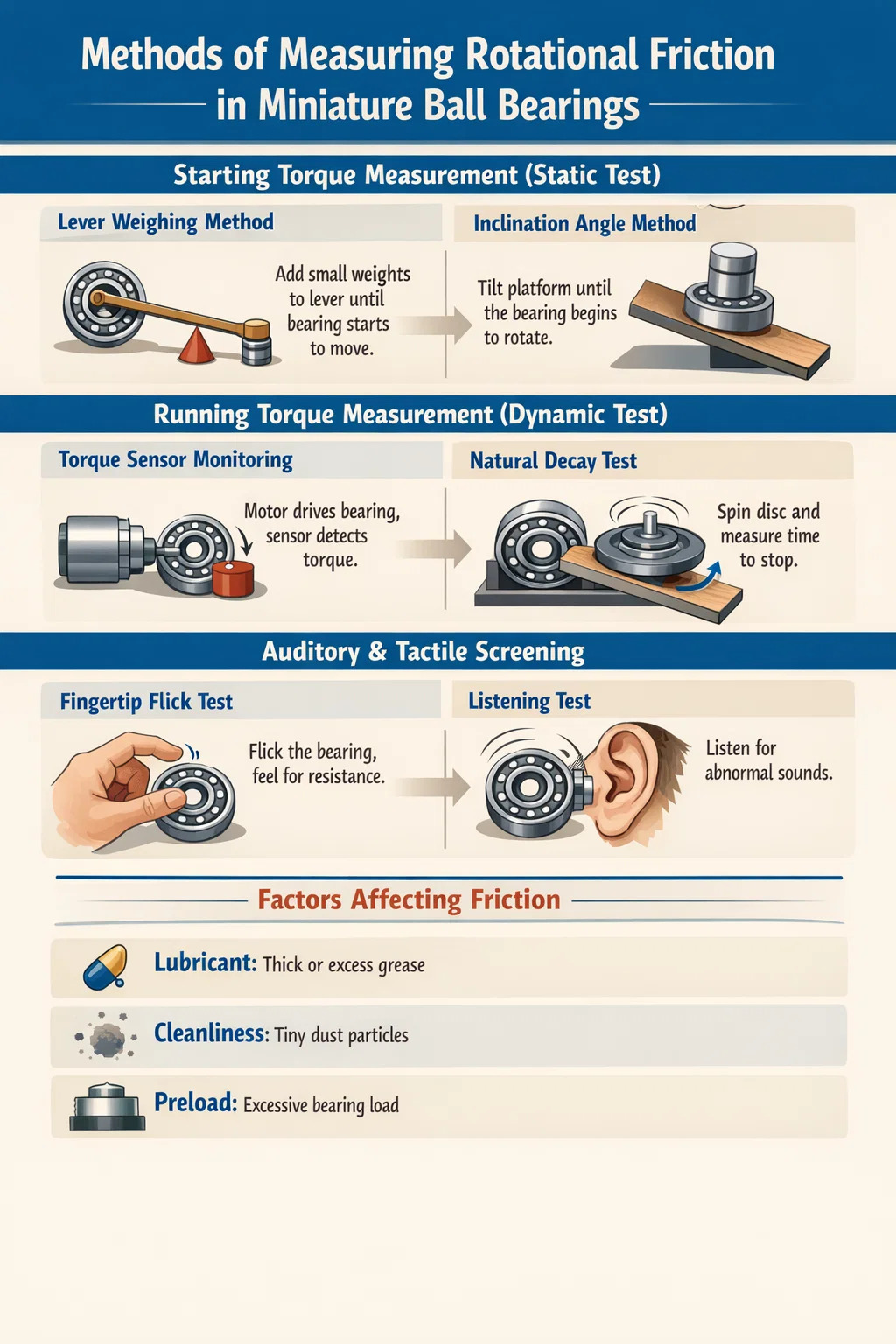

Measuring the rotational friction of miniature ball bearings essentially involves measuring the resistance torque they generate during rotation. Due to the small size and extremely low friction of these bearings, conventional measurement methods are often not sensitive enough.

Here are several commonly used measurement methods:

► Starting Torque Measurement Method (Static Test)

This measures the maximum resistance that the bearing needs to overcome at the moment it transitions from "static" to "rotating."

Lever Weighing Method: A lightweight lever is fixed to the inner ring of the bearing, and small weights are gradually added to the other end of the lever. When the lever is just able to drive the bearing to rotate, the starting friction can be calculated from the weight of the weights and the length of the lever.

Inclination Angle Method: The bearing is mounted on a platform with an adjustable angle, and an object of fixed weight is placed on the bearing. One end of the platform is slowly raised until the bearing begins to slide or rotate. The larger the angle of inclination of the platform, the greater the frictional resistance of the miniature ball bearings.

► Running Torque Measurement Method (Dynamic Test)

If you want to know how the bearing performs during continuous rotation, you can use the following methods:

Torque Sensor Monitoring: This is the most professional method. A miniature motor drives the inner ring of the bearing to rotate at a constant speed, while the outer ring is fixed to an extremely sensitive sensor. The sensor detects the weak force that the outer ring wants to follow, which is the rotational friction.

Natural Decay Method (Free Rotation Test): A small disc with a certain weight is added to the bearing, allowing it to rotate rapidly like a gyroscope. Then the power is removed, and the time it takes from the start of rotation to complete stillness is recorded.

Longer time: Indicates that the ball bearing has less friction and better performance.

Faster stop: Indicates greater internal resistance, possibly due to overly viscous lubricant or impurities.

► Auditory and Tactile Discrimination (Preliminary Screening)

Although it doesn't produce precise values, this is the quickest inspection method most commonly used by experienced technicians.

Fingertip Flick: Hold the inner ring with your fingers and quickly flick the outer ring. Feel for any resistance, jumping, or subtle grinding sounds. High-quality miniature ball bearings should rotate as smoothly as silk, with virtually no vibration.

Auditory diagnosis: Place the bearing near your ear and rotate it, or use a simple listening stick. A uniform, faint sound is normal. If you hear a periodic "clicking" sound, it indicates that there may be wear or tiny particles inside.

► Factors affecting friction

During the measurement process, you will find that the following factors significantly change the results:

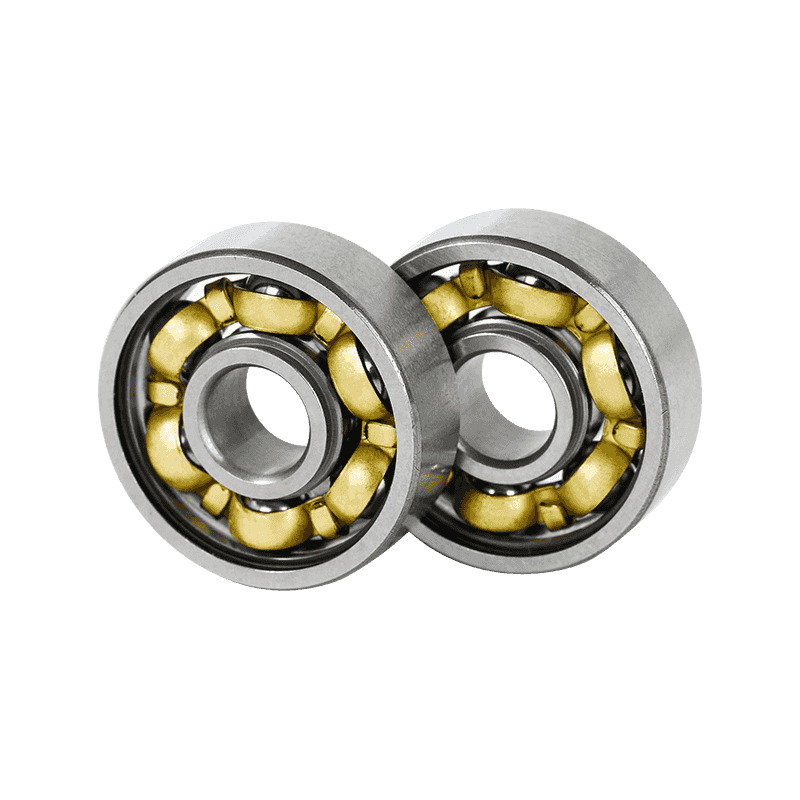

Lubricant: Too much or too viscous grease will increase the resistance during rotation (i.e., "grease drag").

Cleanliness: Even a single dust particle invisible to the naked eye falling into the miniature ball bearings can cause the friction to spike instantly.

Preload: If the bearing is pressed too tightly during installation, the pressure between the balls and the raceway increases, and the friction will also increase accordingly.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch