What are the smallest ball bearings? Let's find out!

Content

In the engineering field, the smallest ball bearings are classified as "miniature bearings" or "instrument bearings." These precision-engineered small parts not only push the limits of manufacturing technology but are also crucial for the proper functioning of many cutting-edge devices.

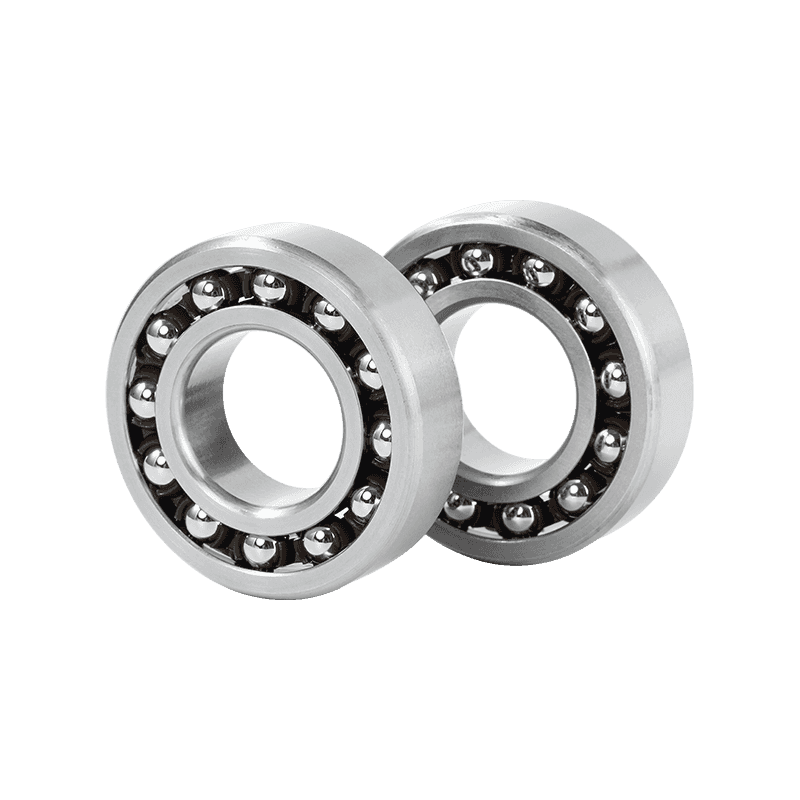

◆ Definition of Miniature Bearings

While "small" is a relative concept, in the bearing industry, bearings with an inner diameter smaller than a certain standard are generally referred to as miniature bearings.

Miniature World:

The size of these ball bearings is surprisingly small; some are even about the size of the ball in a ballpoint pen. Imagine fitting inner and outer rings, even smaller steel balls, and a cage to hold them in a space smaller than a sesame seed.

Precision Manufacturing:

Due to their tiny size, any minute dust particle or a single strand of hair can cause the bearing to seize. Therefore, these extremely small ball bearings must be manufactured and assembled in an extremely clean environment.

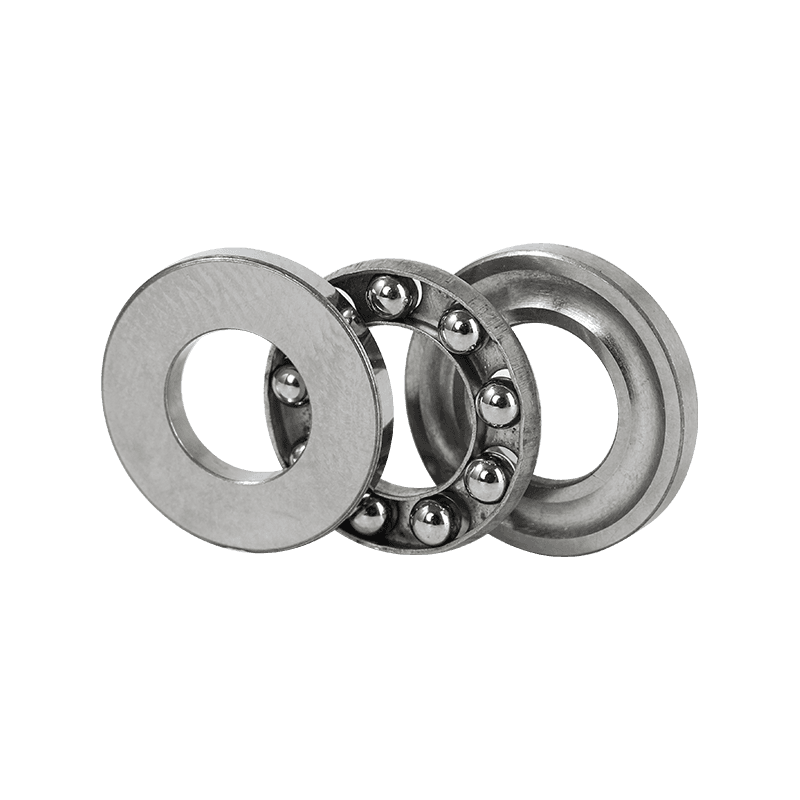

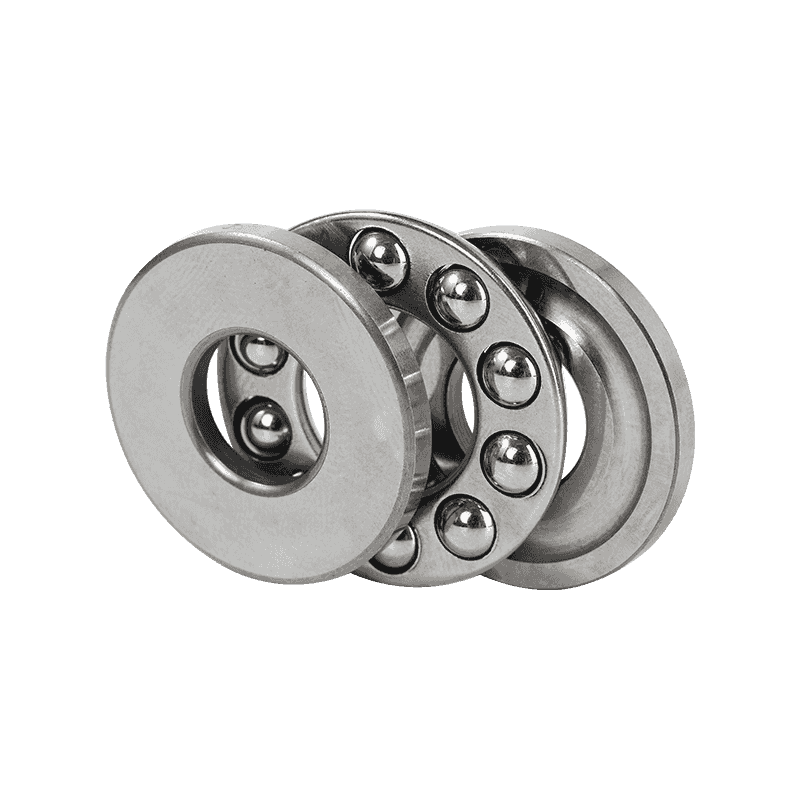

◆ Where do they play a role?

These tiny ball bearings are not just for show; they solve rotation problems in high-precision equipment:

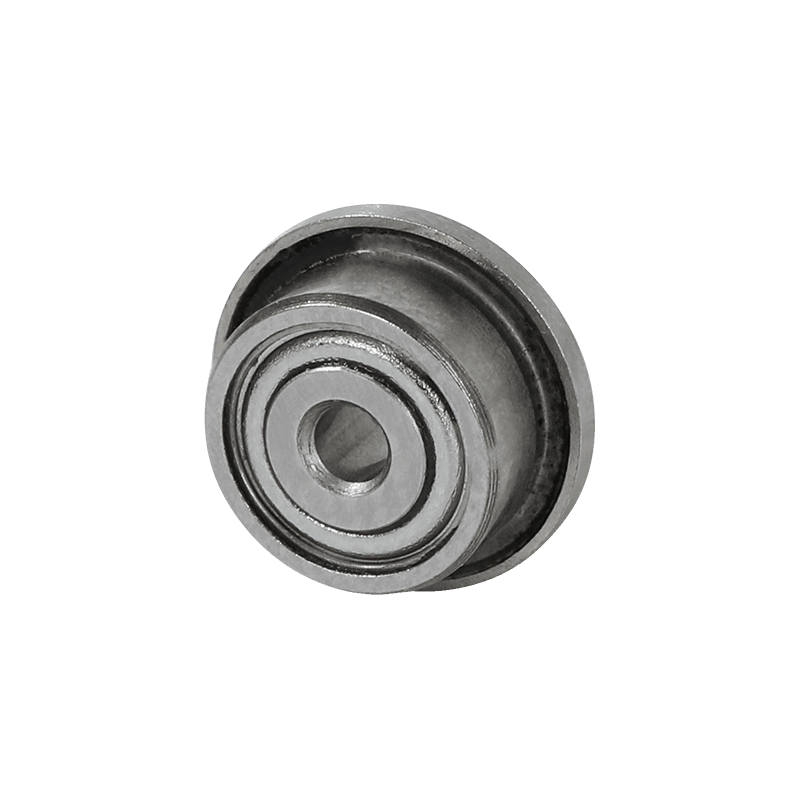

Dentist's Small Drill:

When you're at the dentist, the high-speed, high-pitched dental handpiece (drill) contains extremely small ball bearings. They must support ultra-high-speed rotation of hundreds of thousands of revolutions per minute while ensuring no overheating or vibration.

Precision Medical Robots:

During minimally invasive surgery, the "fingers" of the robot require extremely precise and smooth movements, and miniature bearings ensure these movements are lag-free.

High-End Precision Instruments:

Pointers on aircraft instrument panels, or high-precision flow meters in laboratories, require ball bearings with almost zero friction to sense the slightest changes in force.

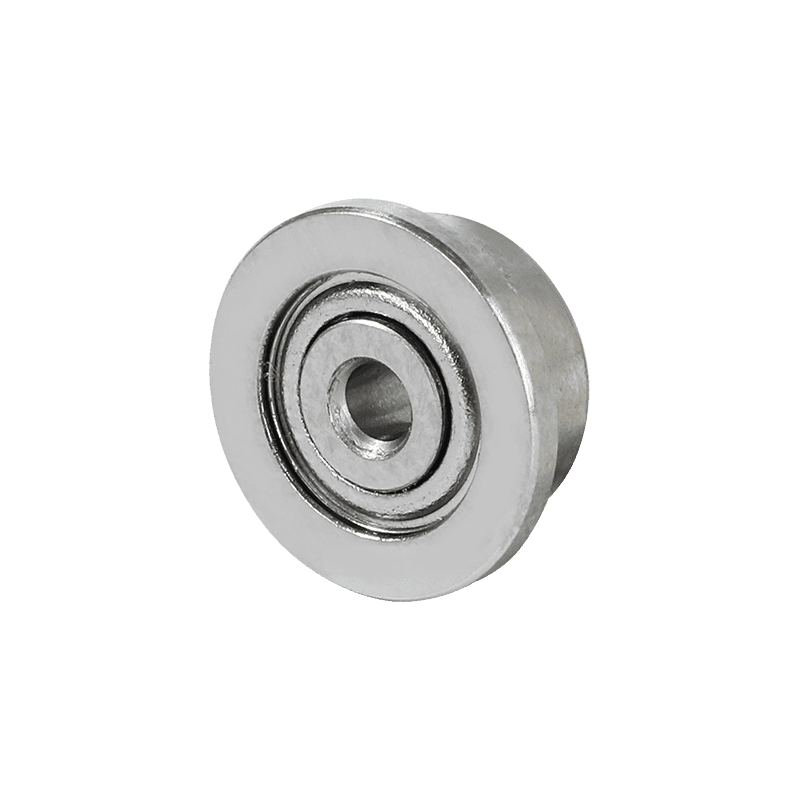

Electronic Device Cooling:

Cooling fans in some ultra-thin laptops or high-end drones use extremely small bearings to reduce size and ensure quiet operation.

◆ Materials and Characteristics

To maintain strength at such small sizes, the materials used in these ball bearings are carefully selected:

Special Steel:

High-purity stainless steel is typically used to prevent rust and improve durability.

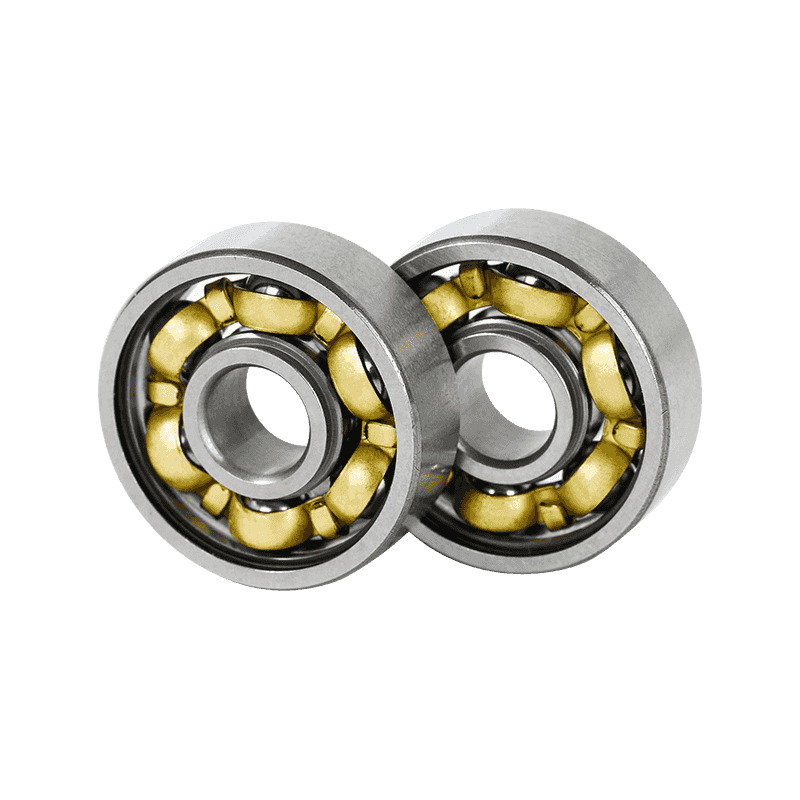

Ceramic Balls:

In some extremely demanding applications, the internal balls are replaced with ceramic material. Ceramic balls are lighter, harder, and have less friction than steel balls, making them ideal for high-speed operation in miniature spaces.

Extreme quietness:

The smaller the bearing, the higher the noise requirements usually are. They rotate almost silently to avoid interfering with the signals of precision instruments.

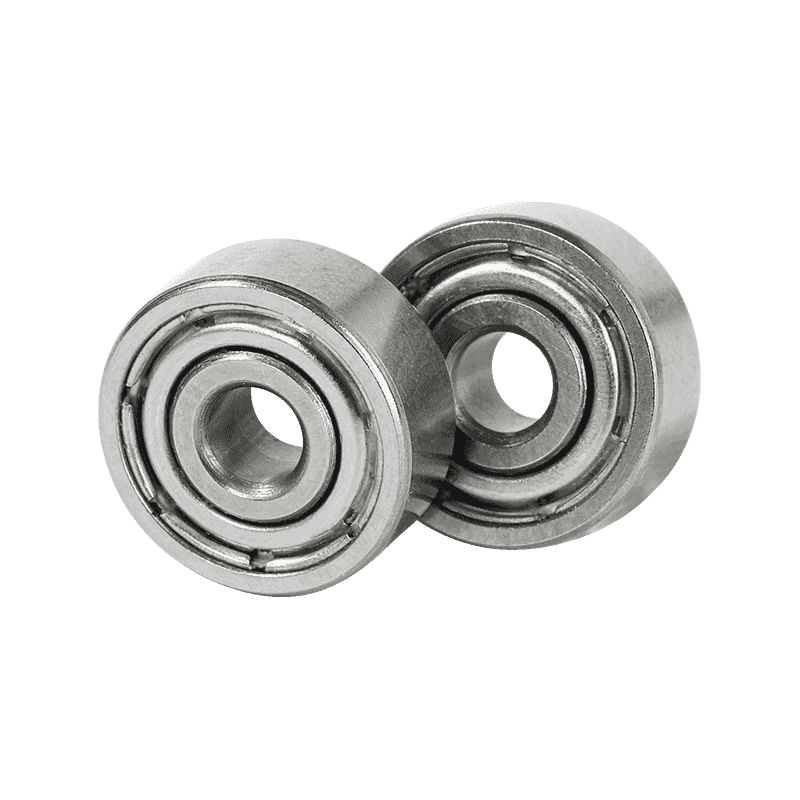

◆ Maintenance and Protection

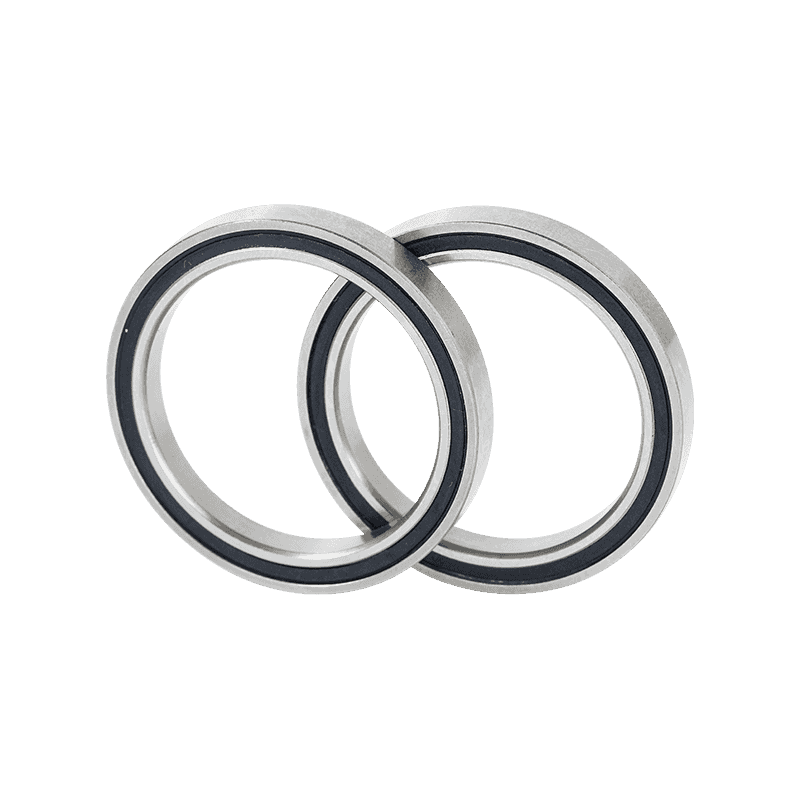

Because these ball bearings are so delicate, they usually come with very precise "dust covers."

Fully sealed design: This cover securely locks the lubricating grease inside while preventing external debris from entering, ensuring that this "microscopic world" can continue to operate for many years.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch