How do ball bearings work? What are the core technical principles?

Content

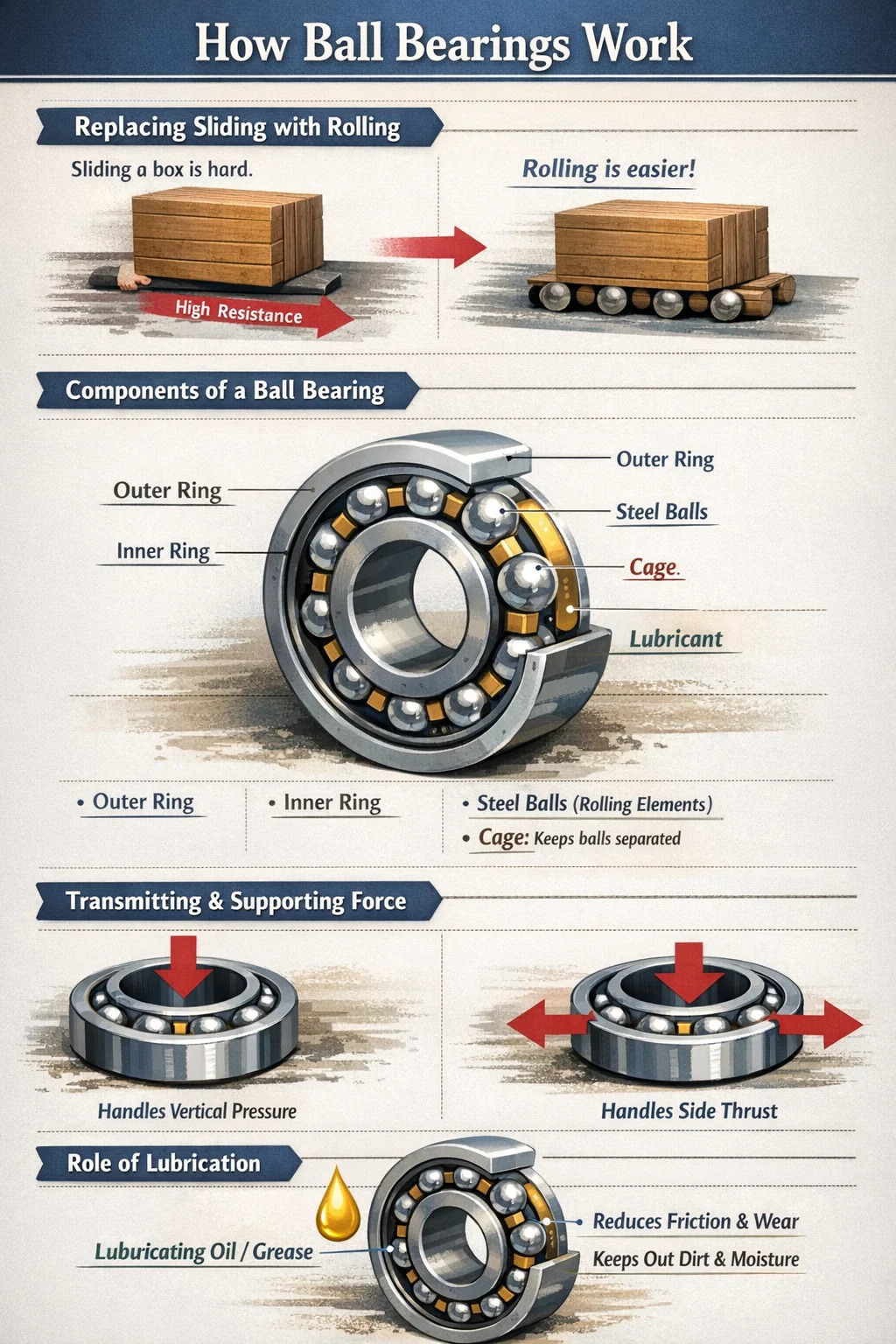

The working principle of ball bearing is actually very intuitive. Simply put, they make machines run more easily by "converting sliding motion into rolling motion."

Here's a detailed explanation:

→ Core Principle: Replacing friction with rolling

If you try to push a heavy wooden box across the ground, you'll feel a lot of resistance – this is "sliding friction." But if you place several cylindrical wooden rods under the box, it will be much easier to push.

Ball bearings work in the same way. They use small, smooth balls inside to transform the intense "friction" between parts into smooth "rolling."

Because the contact area between the balls and the inner and outer rings is very small (almost a point), the resistance generated is extremely low, and energy loss is minimized.

→ Internal Components and their Functions

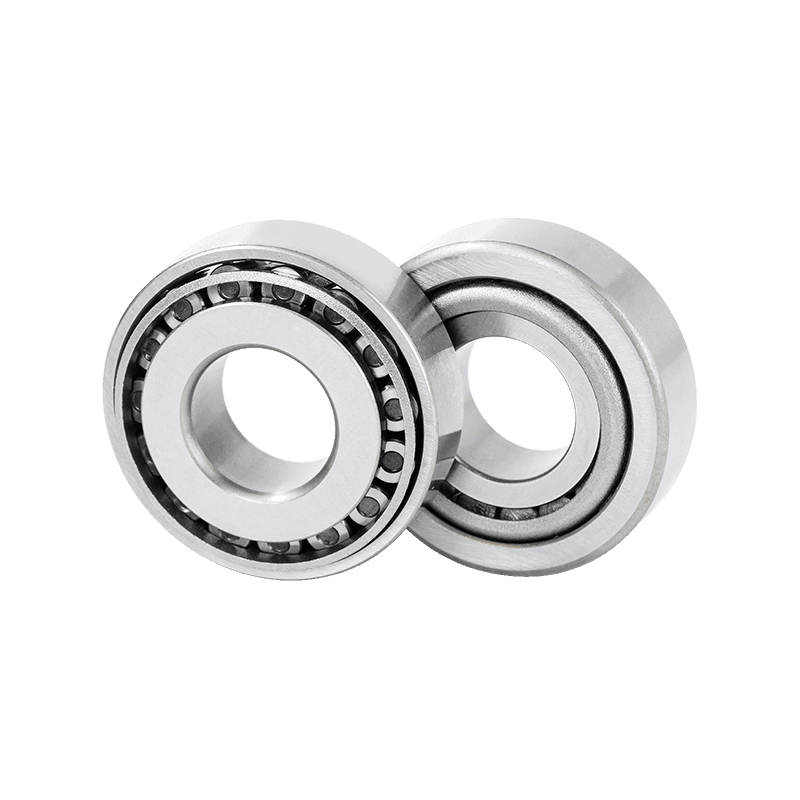

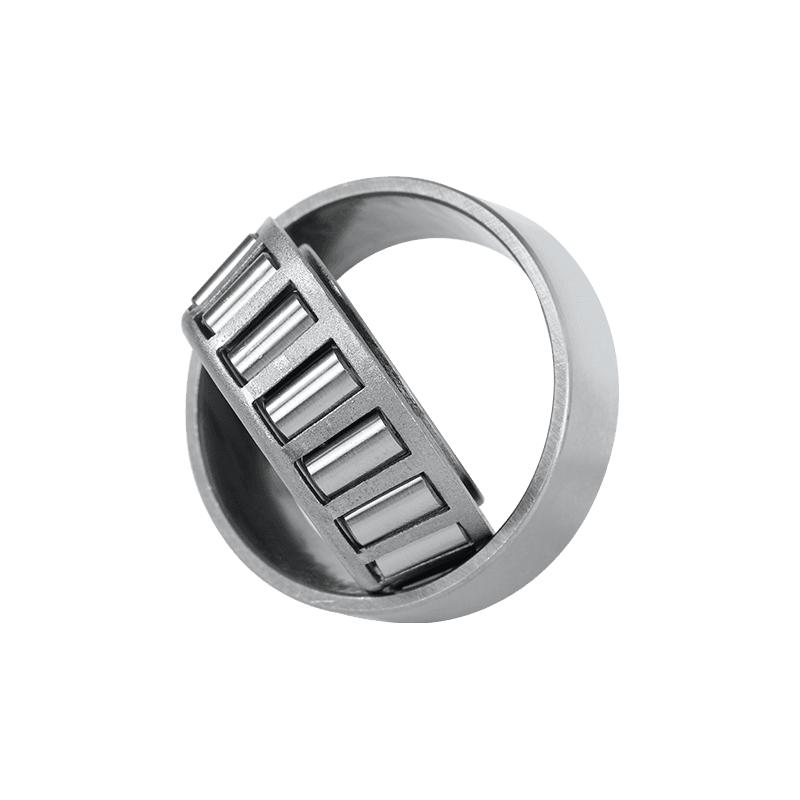

A standard ball bearing consists of several key parts working together:

Outer and Inner Rings: The inner ring is usually fitted onto the rotating shaft and rotates with the shaft; the outer ring is fixed to the machine's base. A precise gap is maintained between the two.

Steel Balls (Rolling Elements): These precisely manufactured small spheres are embedded in the grooves (raceways) of the inner and outer rings. When the inner ring rotates, the steel balls roll within the raceways.

Cage: Its function is like a "dormitory manager," separating each ball to prevent them from crowding together and colliding, ensuring that each ball evenly distributes the weight.

→ Supporting and Transmitting Force

Ball bearings are not just for faster rotation; they also bear weight.

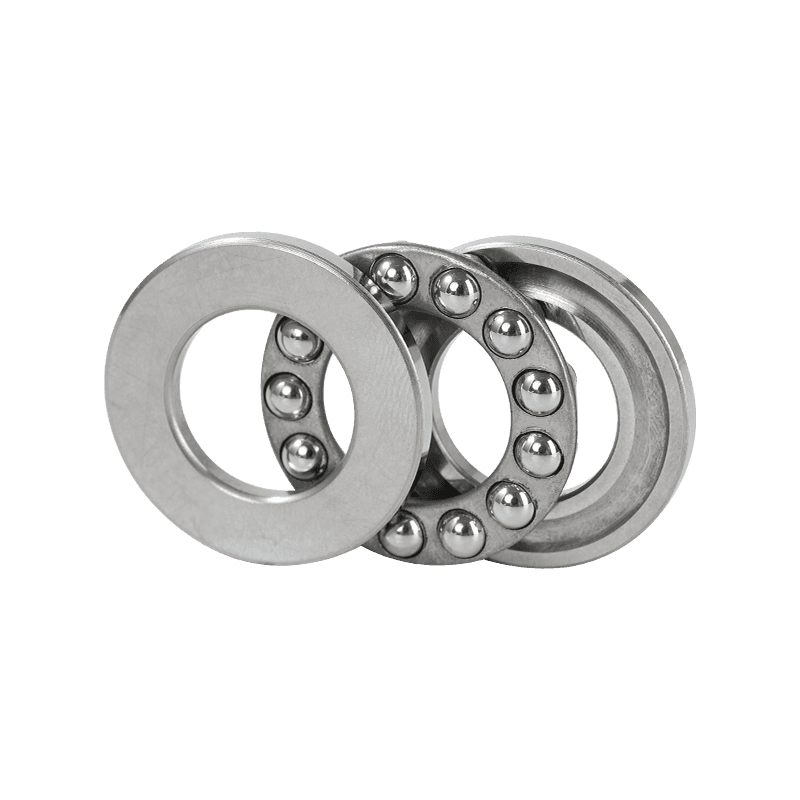

Pressure Distribution: When the machine operates and generates pressure, this pressure is transmitted from the outer ring to the steel balls, and then from the steel balls to the inner ring (or vice versa).

Multi-directional Load Bearing: They can handle forces in different directions. For example, the downward force of gravity on a wheel (radial force), or the lateral thrust generated during turning (axial force), can all be mitigated by the rolling motion of the balls.

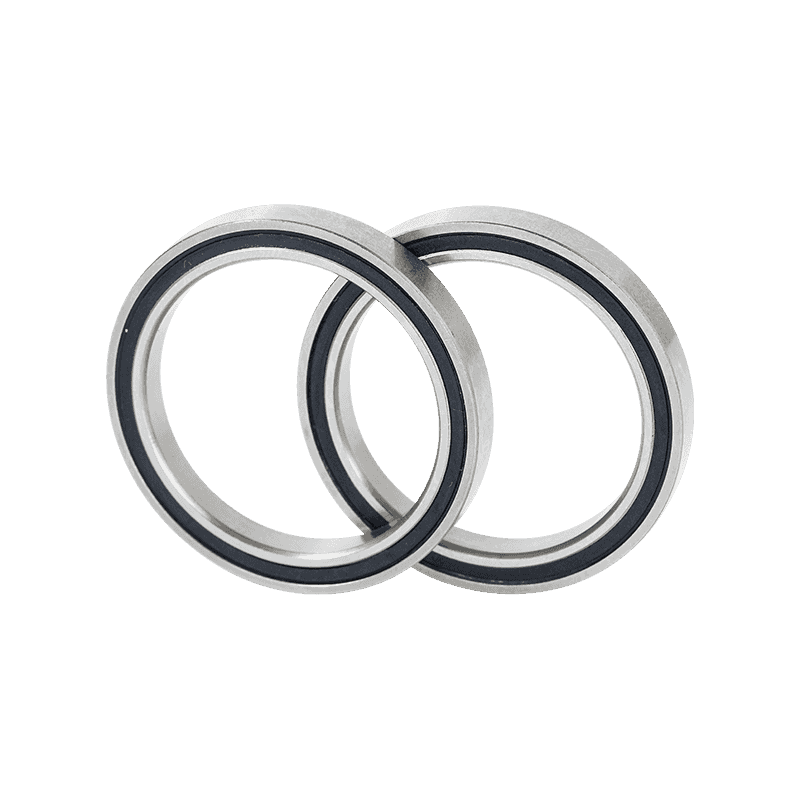

→ The Auxiliary Role of Lubrication

To ensure optimal performance, a thin layer of lubricating oil or grease is usually applied to the inside of ball bearings.

This oil film prevents direct metal-to-metal contact, reduces heat generation, and also prevents dust and moisture from entering the interior, extending the bearing's lifespan.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch