What are ball bearings? An introductory guide.

Content

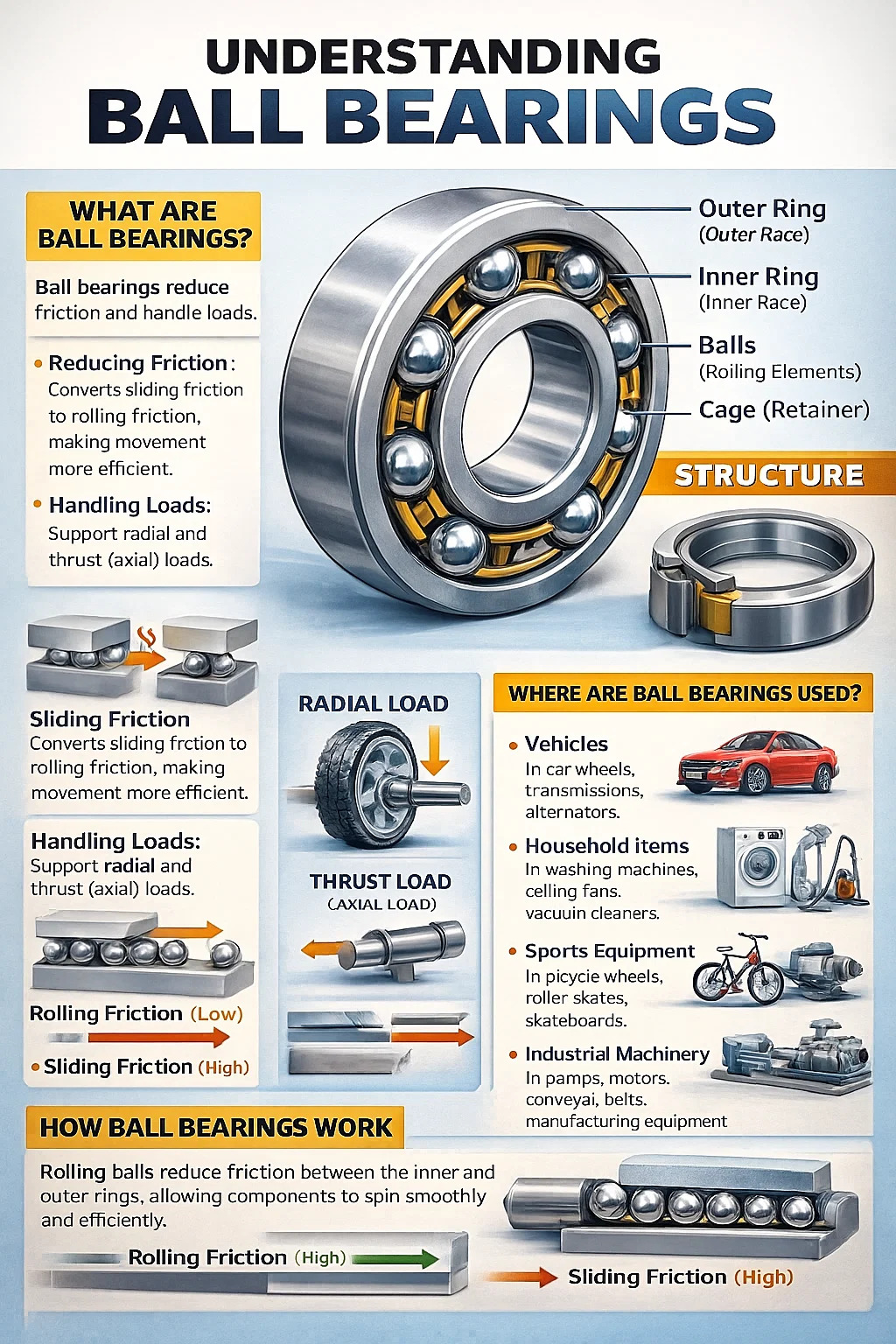

Ball bearings are a very common type of mechanical component used to help things move smoothly and efficiently with minimal effort. Think of them as tiny, essential helpers that allow parts of a machine to spin or roll against each other.

﹃ What Ball Bearings Are

At their core, a ball bearing is a simple device designed to reduce friction and handle loads.

•Reducing Friction: If you try to slide one heavy object across another, you feel a lot of resistance—that's friction. A ball bearing converts this sliding friction into rolling friction. Rolling resistance is much, much lower than sliding resistance, which makes movement easier and saves energy.

•Handling Loads: Bearings support weight and forces. They are particularly good at handling two main types of forces:

•Radial Loads: Forces acting perpendicular to the shaft (like the weight of a spinning wheel).

•Thrust (Axial) Loads: Forces acting parallel to the shaft (like the force pushing a rotating object along its axis).

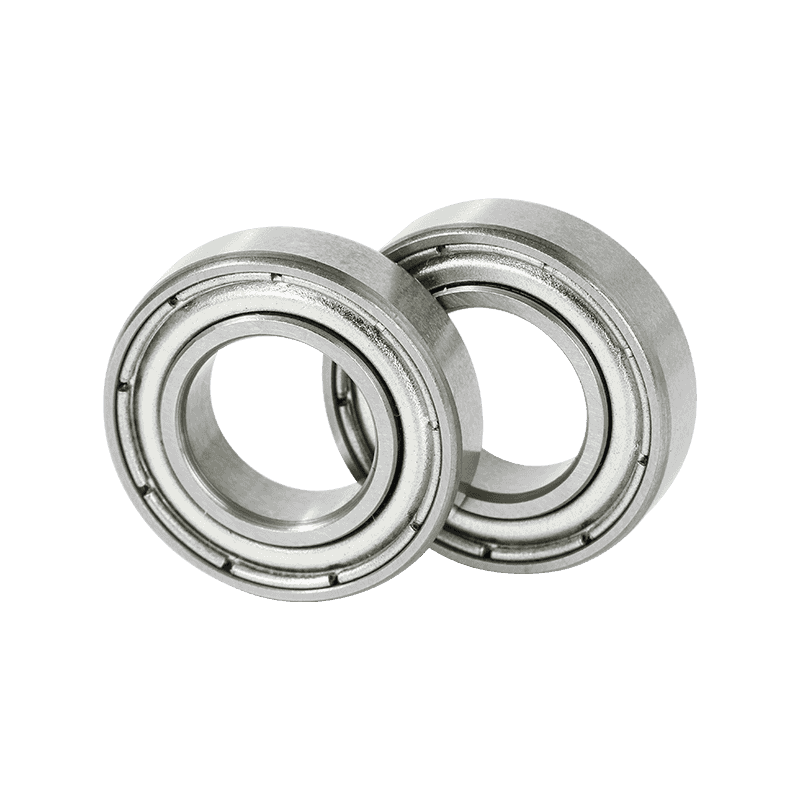

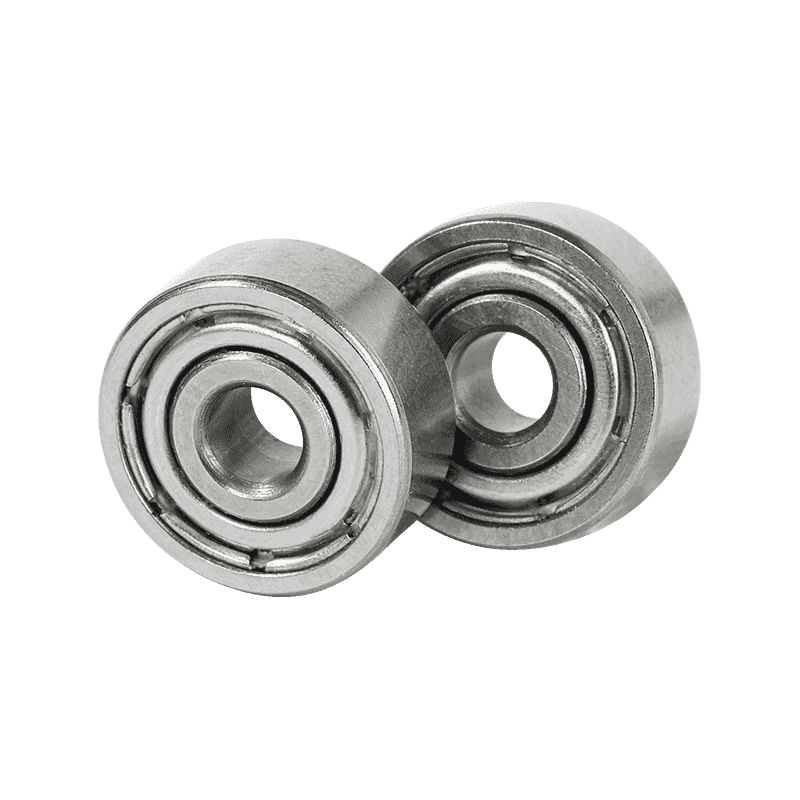

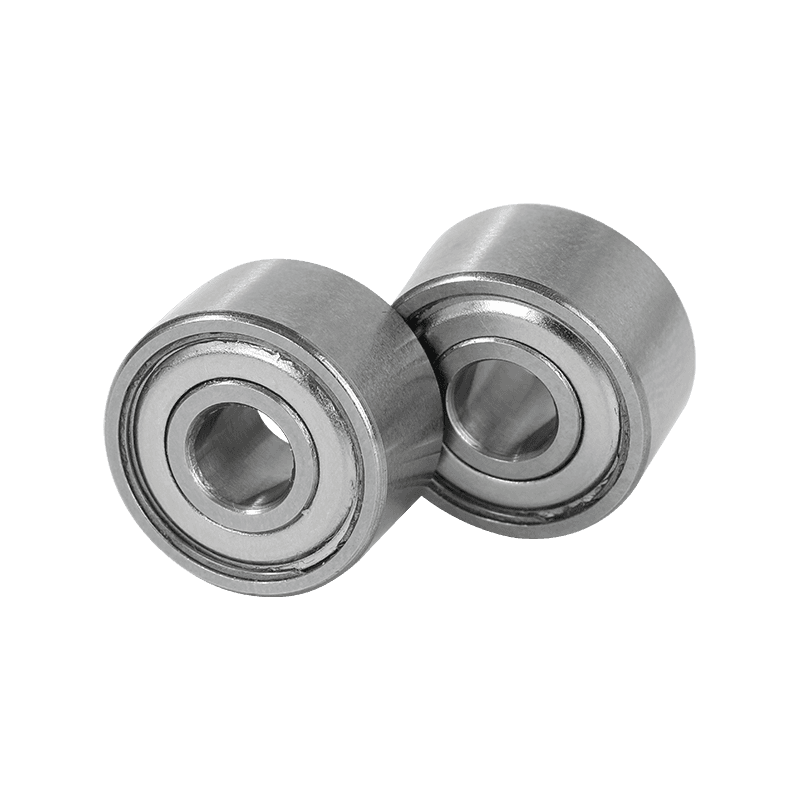

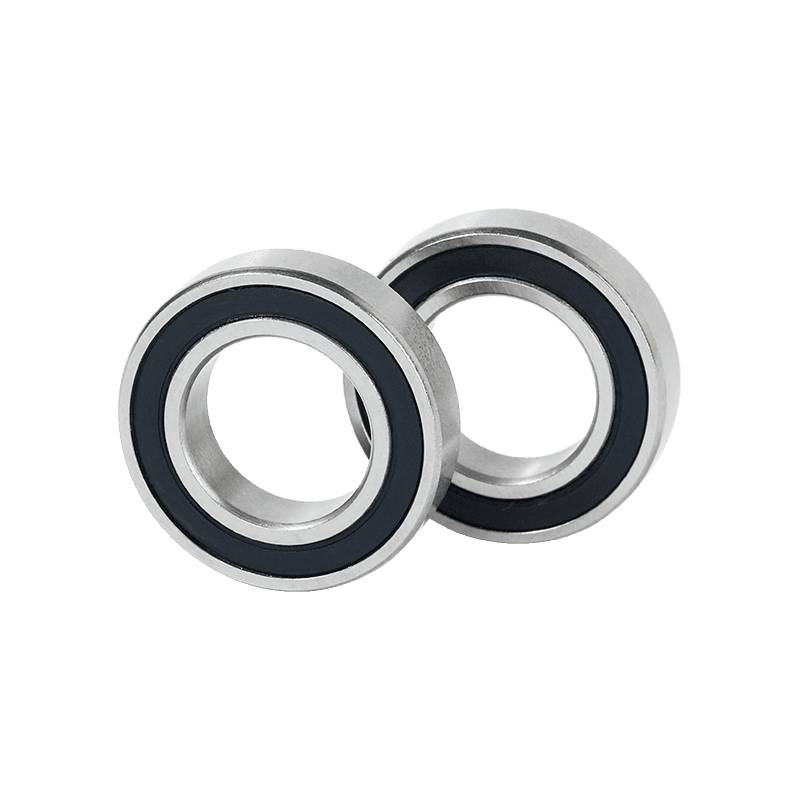

﹃ The Structure of a Ball Bearing

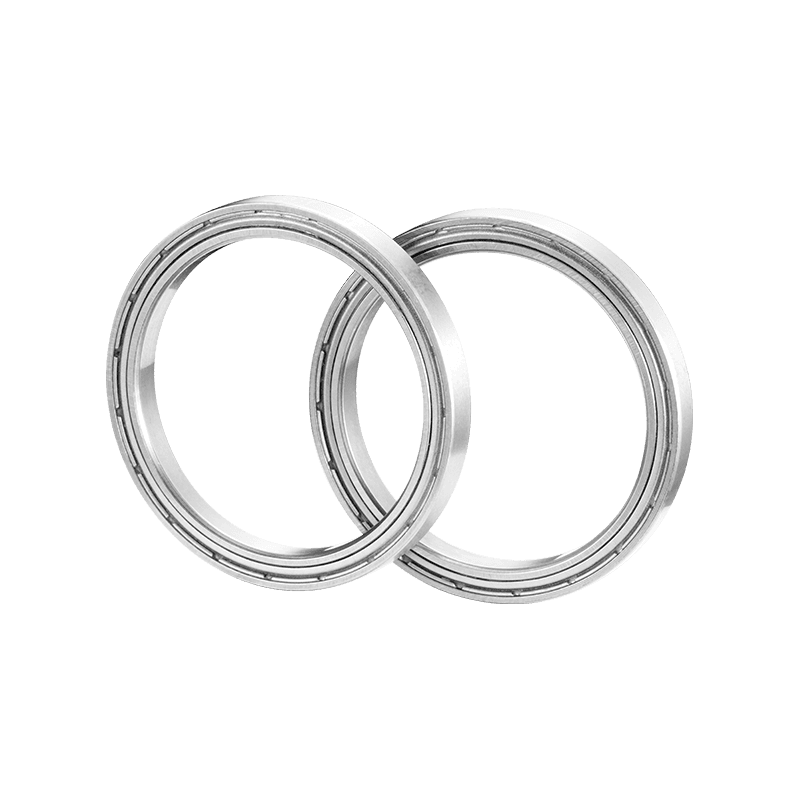

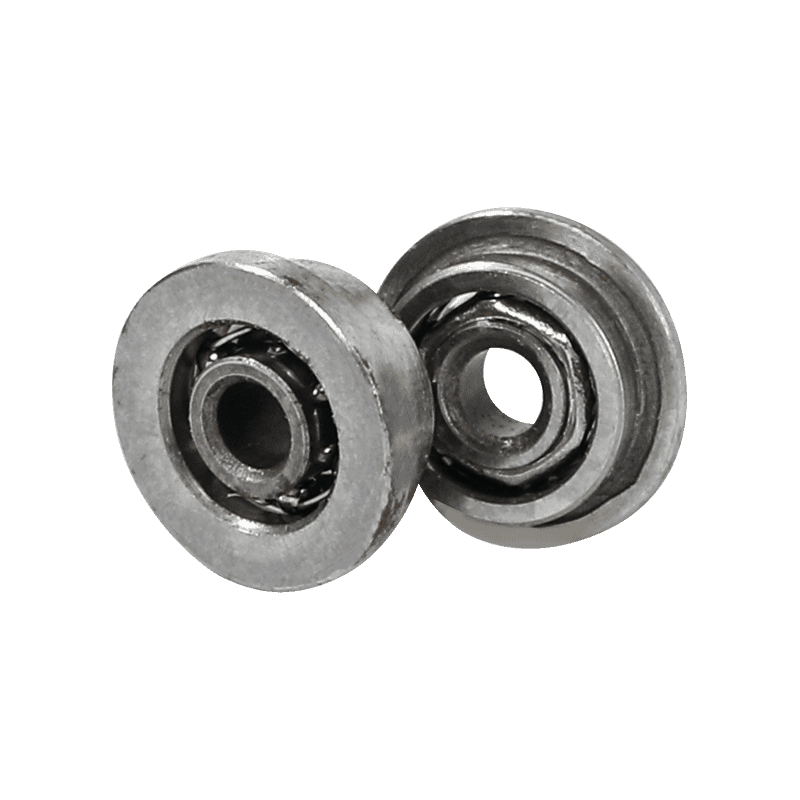

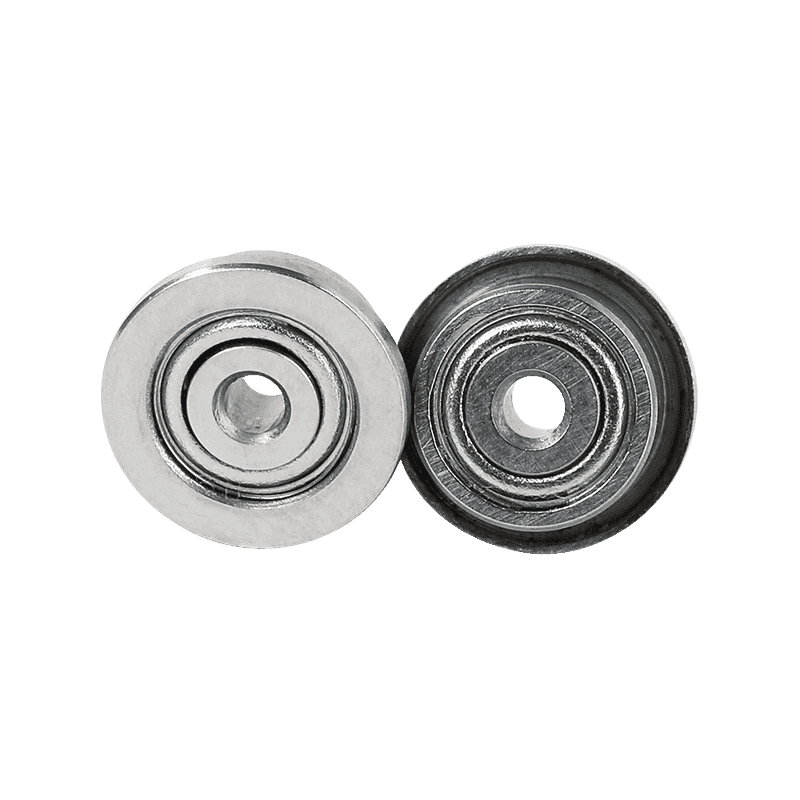

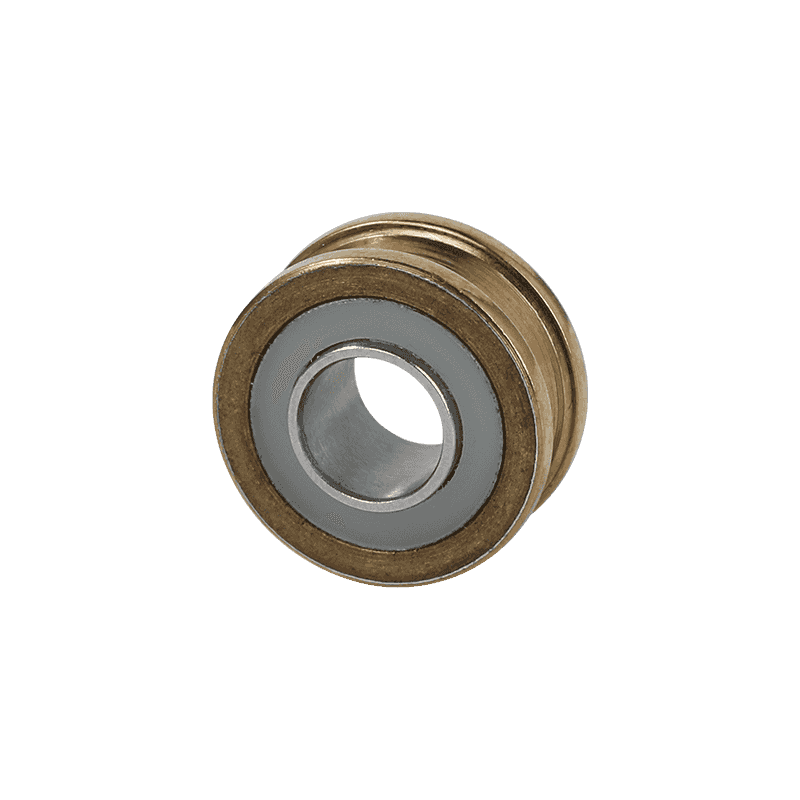

A typical ball bearing is made up of four main parts, arranged concentrically (one inside the other):

•Outer Ring (Outer Race): This is the stationary part, usually fitted into the housing of the machine.

•Inner Ring (Inner Race): This is the rotating part, typically mounted onto a shaft.

•Balls (Rolling Elements): These are the namesake, precision-made spheres situated between the inner and outer rings. They roll to facilitate the movement.

•Cage (Retainer): This keeps the balls separated at equal distances from one another. This is crucial; if the balls touched, they would rub and create friction, defeating the purpose of the bearing.

﹃ Where Are Ball Bearings Used?

You interact with things that use ball bearings every day. They are foundational components in nearly anything that rotates:

•Vehicles: In car wheels, transmissions, and alternators.

•Household Items: In washing machines, ceiling fans, and vacuum cleaners.

•Sports Equipment: In bicycle wheels, roller skates, and skateboards.

•Industrial Machinery: In pumps, motors, conveyor belts, and manufacturing equipment.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch