What size are miniature bearings? Do you know this?

Content

■ Key Feature: Miniature Size

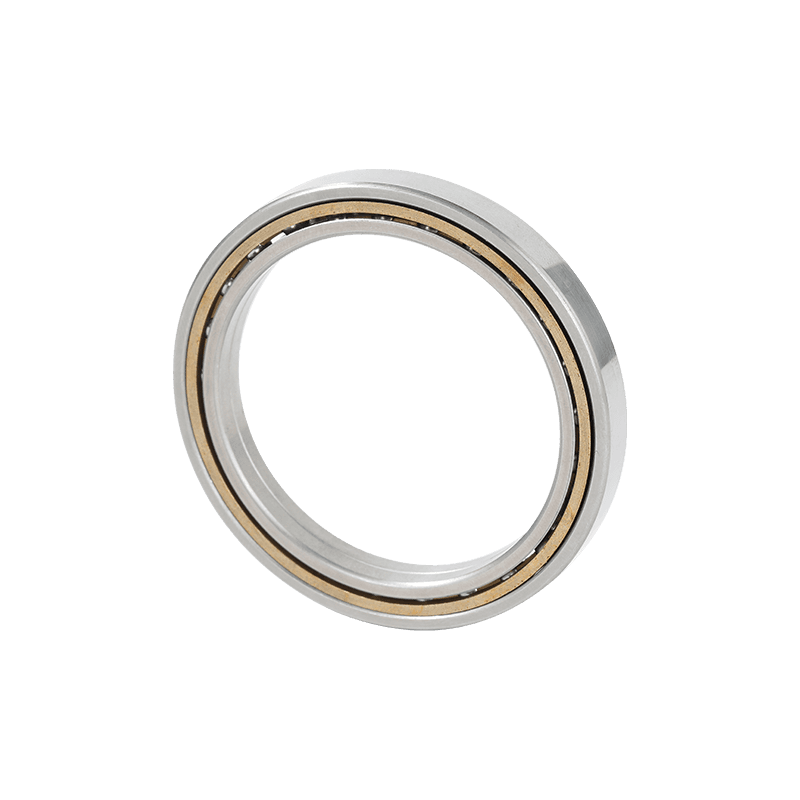

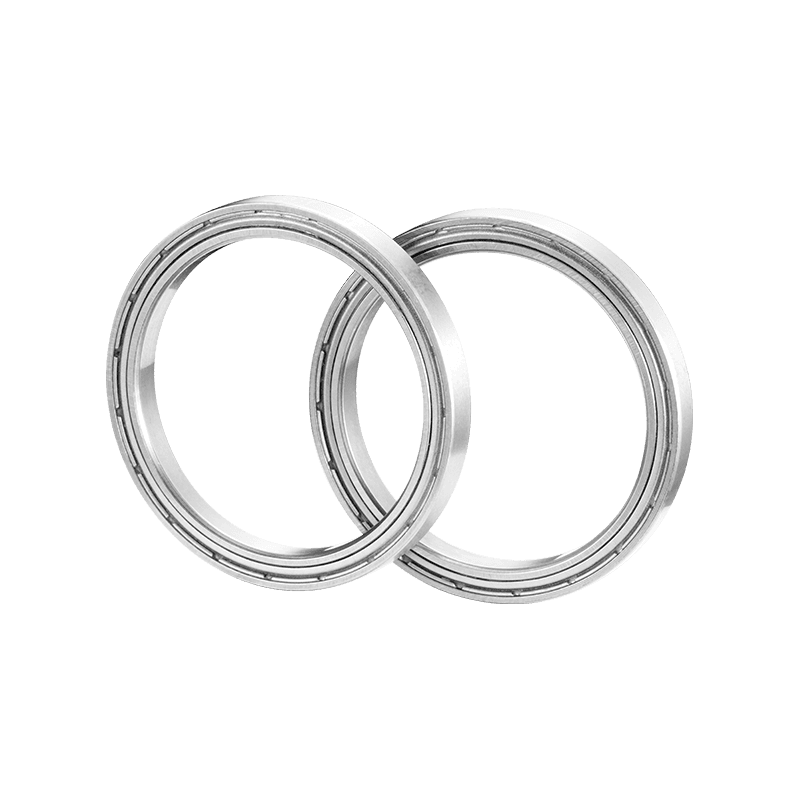

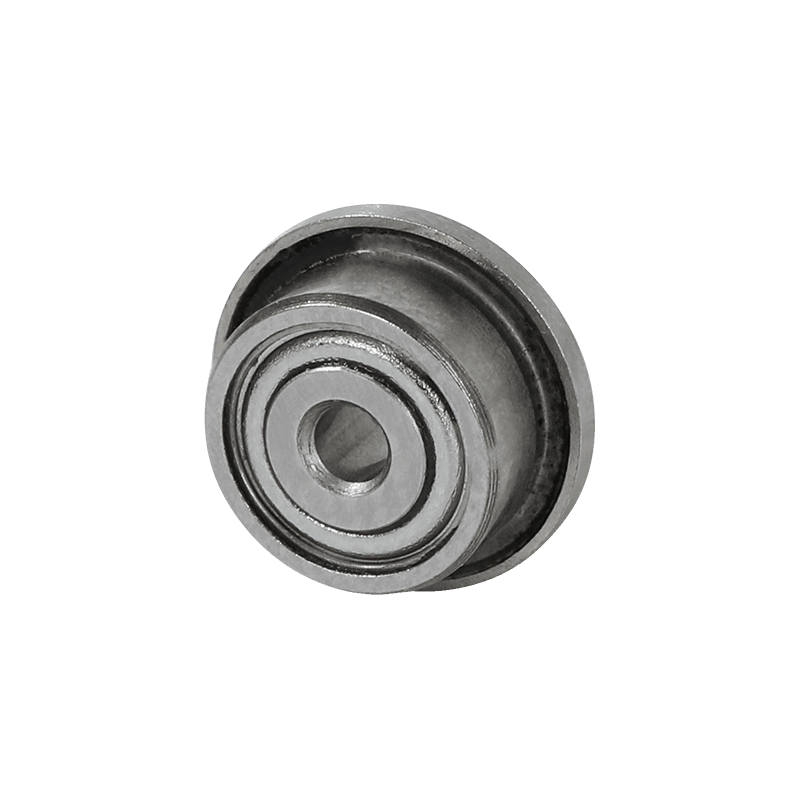

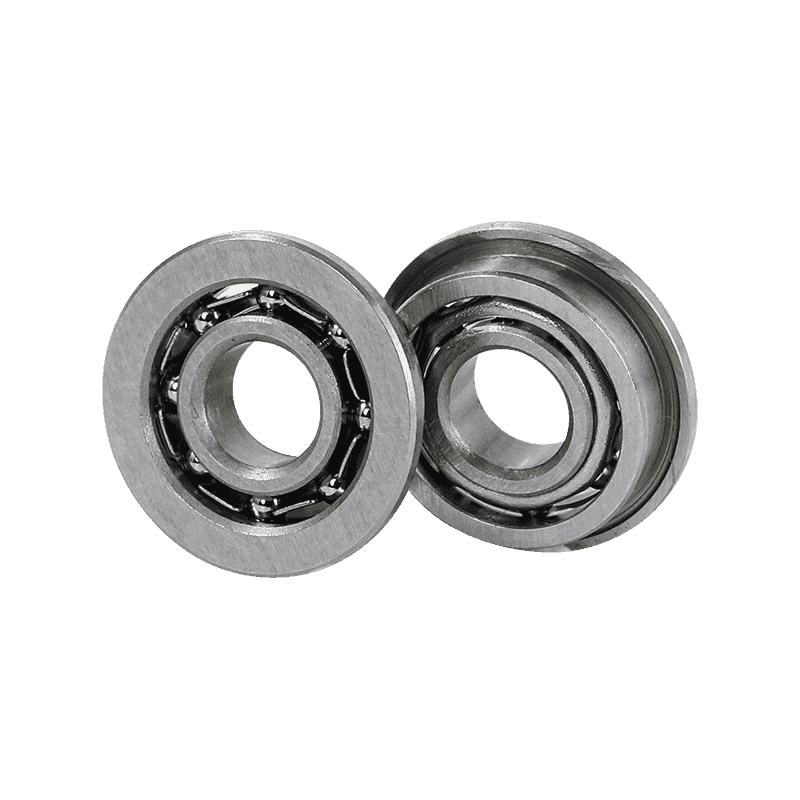

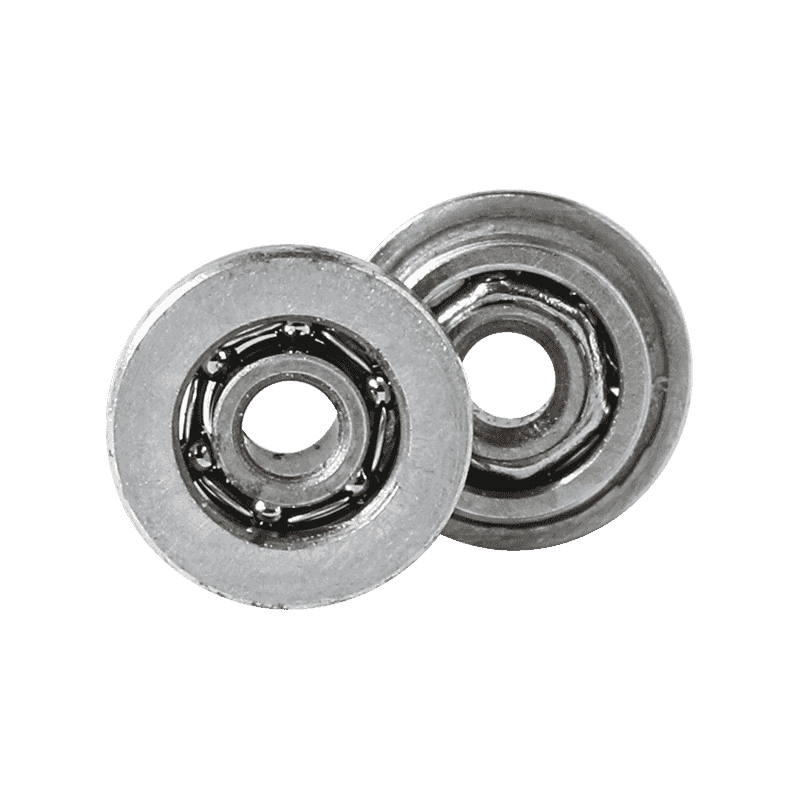

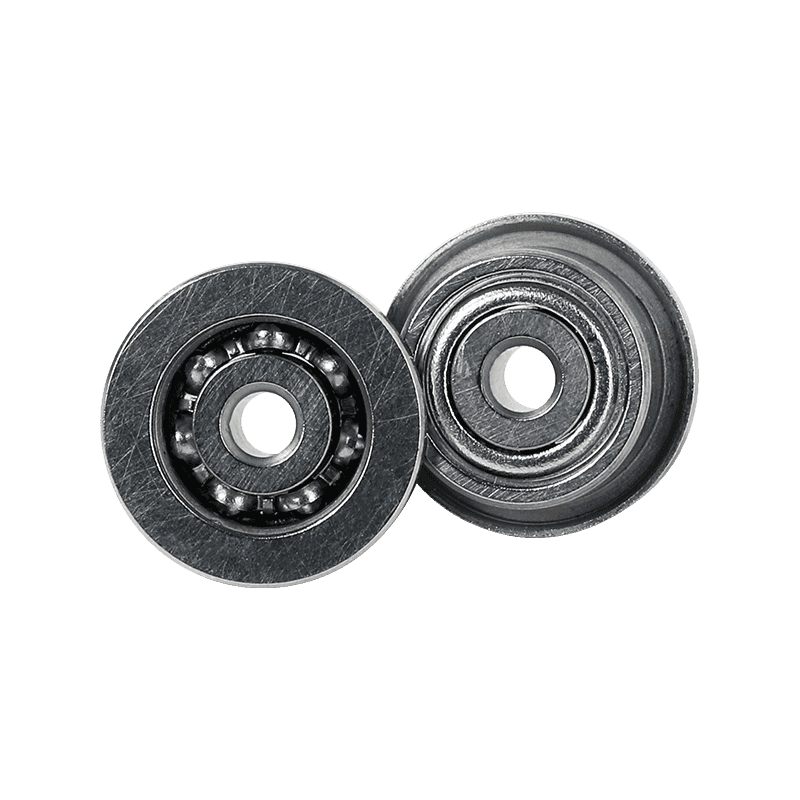

As the name suggests, the most prominent feature of miniature bearing is their extremely small size. They are designed for equipment with extremely limited space where standard-sized bearings cannot fit.

Imagine, they are usually much smaller than the screws you commonly see, some are even about the size of a grain of millet.

■ No Absolute Standard, but a General Range

To be precise, there is no universally unified, rigid numerical boundary for what constitutes a "miniature" bearing. Different manufacturers and industries may have slight variations.

However, in the bearing industry, bearings with an outer ring diameter (the width of the outermost ring of the entire bearing) smaller than a certain specific value are usually classified as miniature bearings. Although this specific value is not given as a concrete number, it is relatively small.

Within this category, based on actual size, they are sometimes further subdivided into "miniature," "ultra-miniature," or "extremely small" grades.

■ Common Size Impressions (Avoiding Specific Numbers)

To give you an idea, we can use some everyday objects as analogies (note that these are analogies, not precise dimensions):

Some miniature bearings are about the size of a mung bean or a small button.

Smaller models may be close to the size of a grain of rice or the thickness of a pencil lead.

The smallest ultra-miniature bearings are truly on the same scale as a grain of millet or a grain of fine sand, incredibly delicate.

■ Key Impacts of "Small Size"

Extremely High Precision Requirements: Because of their small size, any manufacturing error (such as out-of-roundness of the inner and outer rings, slight differences in the size of the balls or rollers inside, or slight misalignment during assembly) will be magnified. Even a slight imperfection can cause the bearing to rotate unevenly, produce noise, or even seize up. Therefore, miniature bearings require much higher manufacturing precision than standard-sized bearings.

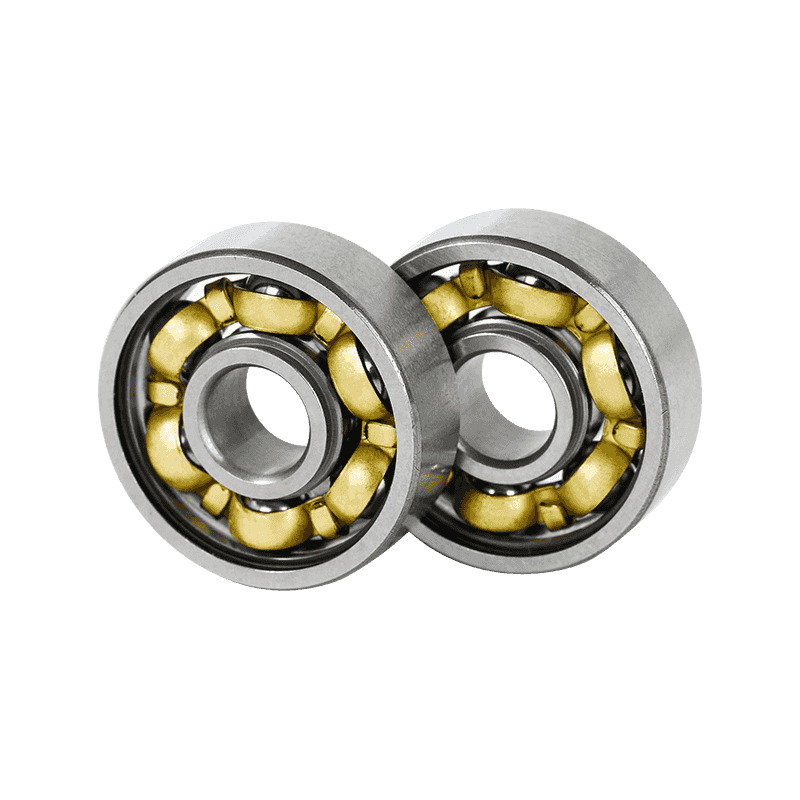

More Delicate Internal Components: The balls or rollers inside also become extremely small, appearing to the naked eye as tiny dots or fine needles. The cage (the small frame that separates the balls) is also made very thin and delicate.

■ Size Determines Application

The size range of miniature bearings directly determines the types of equipment they can be used in:

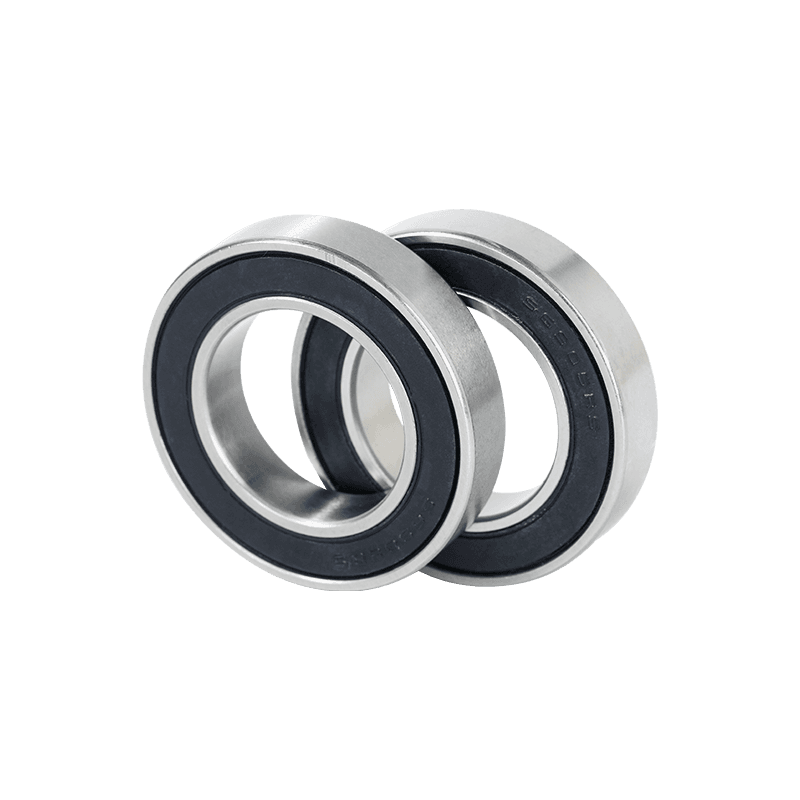

Relatively larger miniature bearings (e.g., similar in size to a small button): may be used in small motors (such as those in some toys and small fans) and office equipment (printer paper feed mechanisms).

Medium-sized miniature bearings (e.g., similar in size to a grain of rice): commonly found in precision instruments (microscope focusing mechanisms), computer hard drive spindle motors, and precision power tools (dental handpieces).

Ultra-miniature bearings (similar in size to a grain of millet or sand): are often used in the most precise applications, such as inside miniature optical devices, at the heart of highly sensitive sensors, in certain miniature medical testing equipment, or in extremely compact miniature motors.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch