What are miniature ball bearings?

Content

Let's talk about miniature ball bearings, which are scaled-down versions of ball bearings, specifically designed for use in equipment with extremely limited space and high precision requirements.

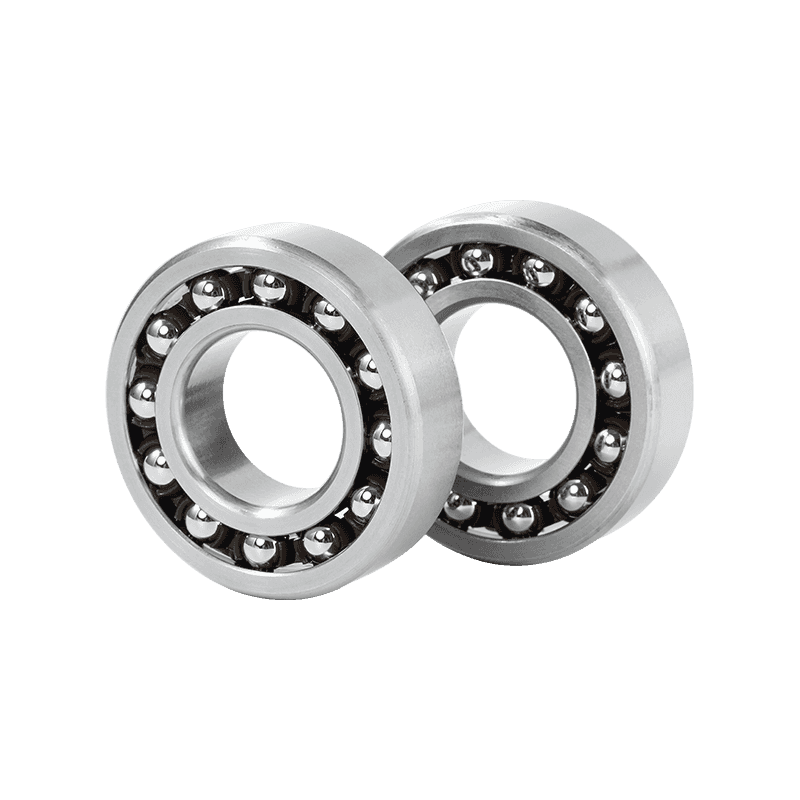

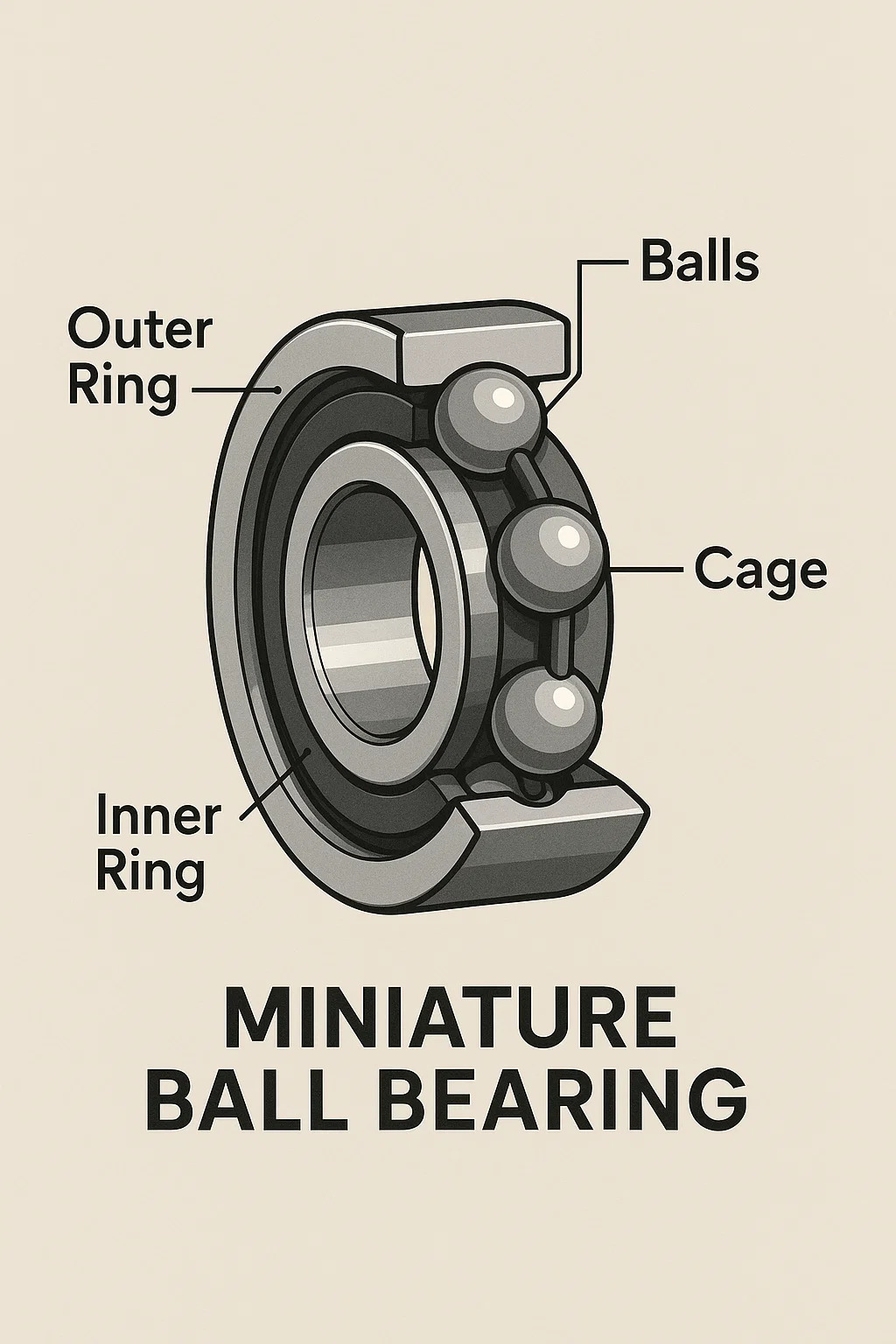

●Basic Structure:

• Imagine it as a very miniature "sandwich".

• The outermost ring is an outer ring, like a small, grooved ring.

• The innermost ring is an inner ring, also a small, grooved ring, which fits onto the shaft to be rotated.

• In the grooves (like a small racetrack) between the inner and outer rings, there is a row of very small steel balls (or ceramic balls), these are the "ball bearings".

• To ensure these tiny steel balls stay aligned and don't crowd together, there is a cage (also called a "cage") in the middle, separating each tiny steel ball.

• Usually, a little grease (like a thick grease) is added inside to make them rotate more smoothly, quietly, and reliably.

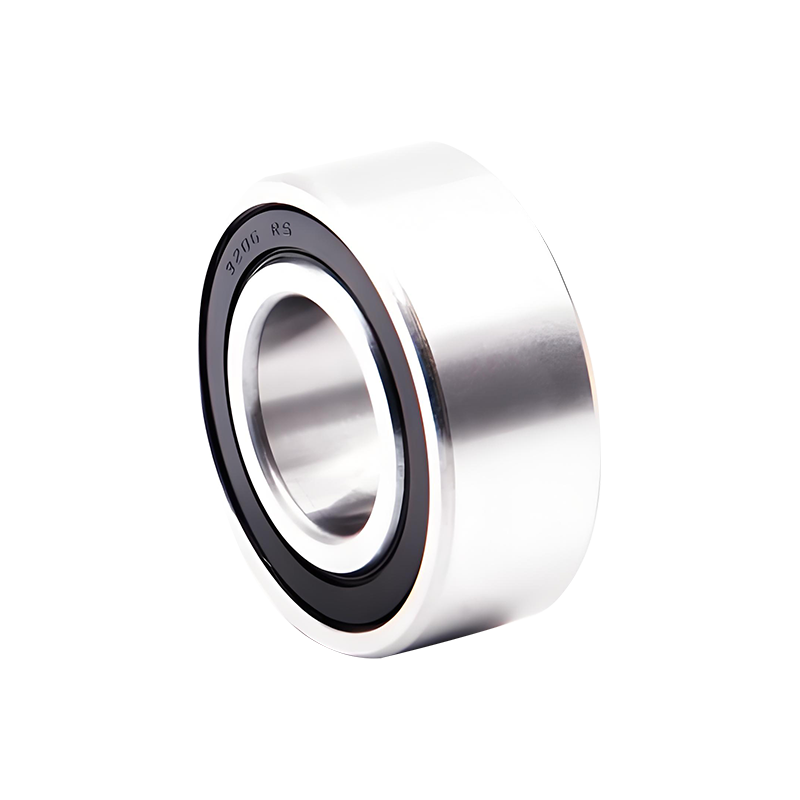

●Core Function (Working Principle):

• Its fundamental task is to allow one thing to rotate smoothly around another, while simultaneously withstanding a certain amount of pressure and tension.

• As the shaft rotates with the inner ring, the tiny steel balls roll within the "track" between the inner and outer rings.

• This "rolling" replaces direct "sliding," significantly reducing friction. Imagine pushing a heavy box; placing a round rod underneath (rolling) is certainly much less strenuous than dragging it directly (sliding).

• It allows rotating parts to rotate more smoothly, with less effort, and more precisely, and can withstand forces from different directions (such as the weight of the shaft or the pressure during operation).

● Where does the "miniaturization" manifest itself?

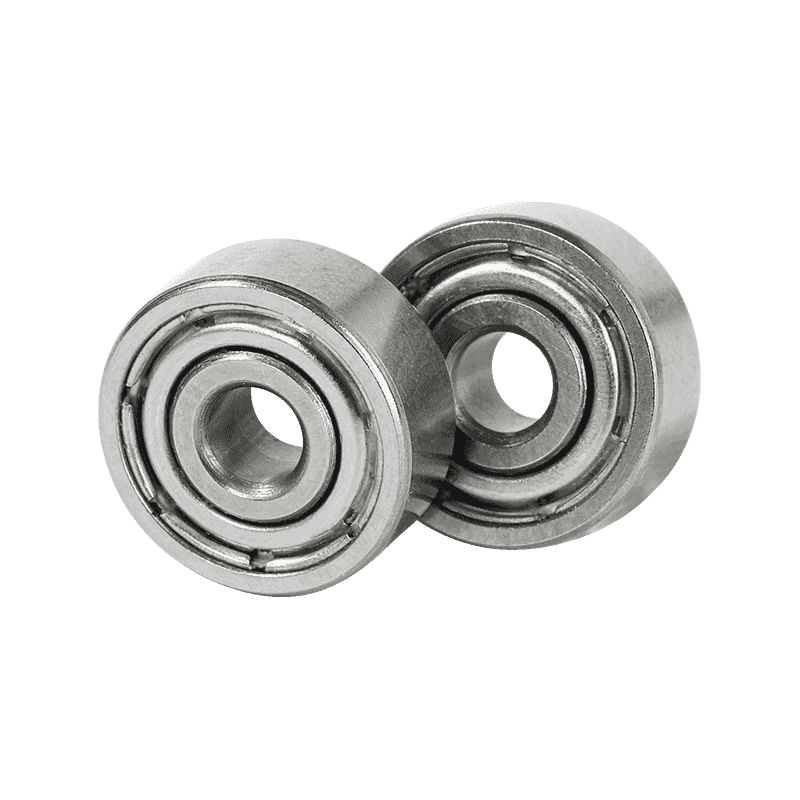

• Extremely small size: This is the most significant characteristic. Their diameter (outer ring size) is typically only a few millimeters to tens of millimeters, or even smaller. The tiny steel balls inside are as fine as grains of sand.

• Extremely high precision requirements: Because of the small size, even a small error is magnified. Therefore, the requirements for the smoothness and roundness of the inner and outer rings, the consistency and roundness of the steel balls, and the overall assembly precision are extremely stringent. It must be made with exceptional precision to function properly.

• High Material Requirements: Commonly made from very hard, wear-resistant, and rust-resistant materials, such as special steel, stainless steel, and even ceramics. Ceramic beads are particularly suitable for small bearings requiring rust prevention, high speed, or high temperature resistance.

● Where are they used?

• Wherever small, precise rotation is required, they are likely to be found:

• Precision Instruments: Adjustment knobs in microscopes, pointer shafts in measuring instruments, lens rotation mechanisms in small optical devices.

• Small Motors: Drone motors, small motors in electric toys, computer cooling fan motors, electric toothbrush motors, model car motors.

• Computer Components: Spindle motors in hard drives, laser head movement mechanisms in optical drives, some computer fans.

• Office Equipment: Paper feed rollers in printers/copiers, moving parts of scanning heads.

• Home Appliances: Small power tools (such as precision drill bits), blades in high-end electric shavers.

• Medical Devices: Dental tools, small surgical instruments, precision testing equipment (requiring extreme quietness, stability, and sterility).

• Models and Toys: Axles, transmission components, and internal servo mechanisms for remote-controlled cars/boats/airplanes.

● Special Requirements:

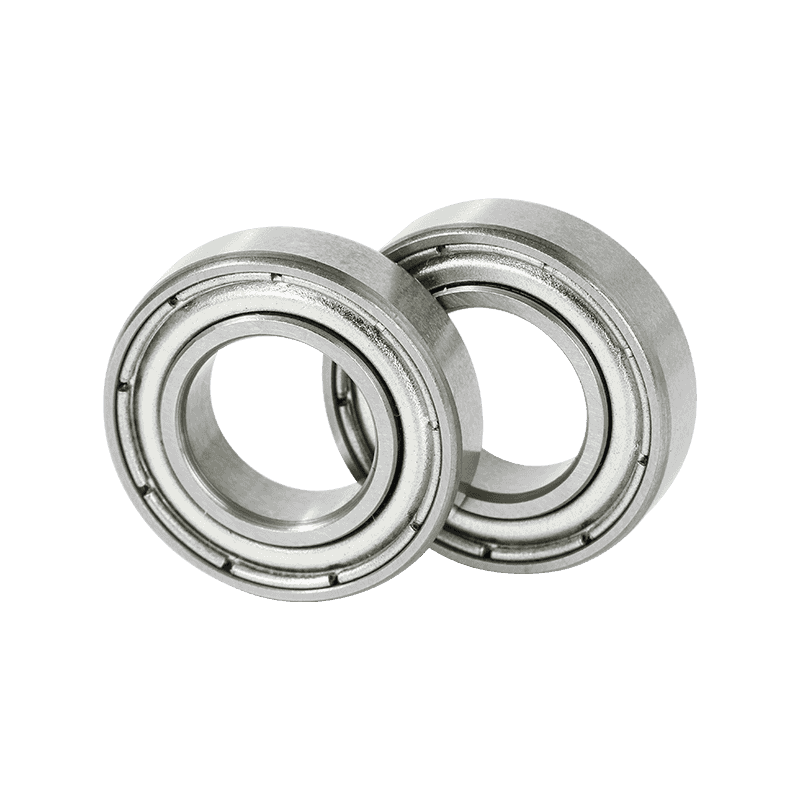

• Cleanliness: Due to the small space and high precision required, even a tiny amount of dust or impurities can cause jamming, noise, or even damage. Therefore, the manufacturing and usage environment must be clean. Some bearings are shipped sealed.

• Lubrication: The amount of grease added is very small, but the requirements are very high. It must be able to work stably for a long time in a small space, without leaking out or drying out.

• Dust and Water Protection: Many miniature ball bearings come with built-in seals or dust covers to prevent dirt and moisture from getting in.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch