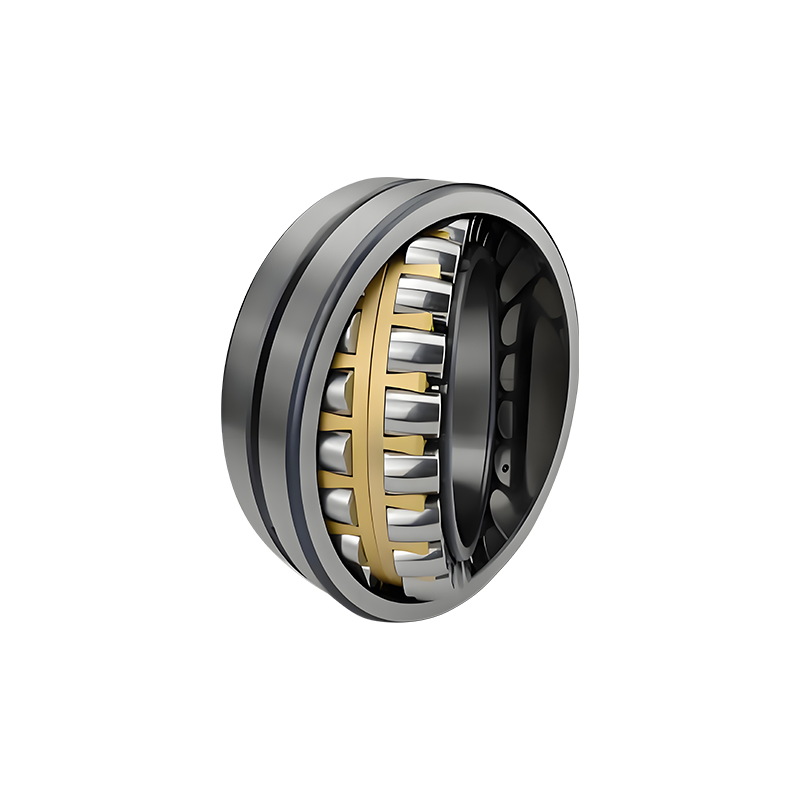

Bearings play a crucial role in industrial machinery, and double-row angular contact ball bearings, as a high-efficiency bearing type, have always been a focus of attention for engineers and manufacturers in terms of design principles and application value. Ningbo Jinxin Bearing Technology Co., Ltd., leveraging its strong R&D capabilities, is committed to providing customers with customized bearing solutions, especially in the field of double-row angular contact ball bearings, capable of precise development and production based on specific drawings or samples.

Question 1: What is the basic definition of a double-row angular contact ball bearing, and what is its position in the bearing family?

A double-row angular contact ball bearing is a common type of rolling bearing, its structure consisting of two single-row angular contact ball bearings combined, designed to simultaneously withstand radial and axial loads. The core feature of this bearing lies in its contact angle design, allowing it to operate stably in high-speed rotational environments, while the double-row layout enhances load-bearing capacity and rigidity. In bearing classification, it is considered a high-performance option, particularly suitable for applications requiring compact space and high reliability. When developing such bearings, Ningbo Jinxin Bearing Technology Co., Ltd. utilizes its team's expertise to optimize designs based on customer requirements, ensuring precise matching at the definition level, thus achieving a seamless transition from concept to finished product.

Question 2: How does the internal structure of a double-row angular contact ball bearing affect its performance?

This type of bearing typically includes multiple components such as inner and outer rings, rolling elements (spherical bodies), a cage, and seals. The double-row design means the balls are divided into two groups, each with a specific contact angle, allowing the bearing to handle combined loads—a combination of radial and axial forces—within a single unit. The advantage of this layout is that it increases overall rigidity and stability by increasing the number of contact points, while reducing the risk of wear. It is worth noting that the optimization of the internal structure directly affects the bearing's lifespan and efficiency; for example, the cage design can affect lubrication distribution and operating noise. In this field, the R&D team at Ningbo Jinxin Bearing Technology Co., Ltd. excels at analyzing structural details and performing reverse engineering based on customer samples or drawings to ensure that the manufactured bearings meet strict tolerance standards and the requirements of various demanding operating conditions.

Question 3: What are the unique advantages of double-row angular contact ball bearings compared to other bearing types?

The advantages of double-row angular contact ball bearings are mainly reflected in their versatility and durability. First, due to its double-row design, it can simultaneously handle high radial and axial loads, which is often difficult to achieve in single-row bearings. Second, the optimized contact angle allows it to maintain low friction and low heat generation during high-speed rotation, thereby improving overall mechanical efficiency. Furthermore, its compact structure makes it highly valuable in space-constrained applications, reducing equipment size and complexity. These advantages make double-row angular contact ball bearings the preferred choice in industrial automation, precision machinery, and other fields. Ningbo Jinxin Bearing Technology Co., Ltd. fully considers these characteristics during the development process, leveraging its R&D capabilities to customize bearing solutions for customers, ensuring that products not only leverage these advantages but also maximize performance in specific applications.

Question 4: In which industrial applications are double-row angular contact ball bearings commonly used, and how do they solve practical problems?

These bearings are widely used in scenarios with high rotational speeds and complex loads, such as machine tool spindles, motor drive systems, wind turbines, and automotive transmissions. In these applications, the double-row design helps solve problems such as equipment vibration, noise, and premature failure—by effectively distributing loads, it improves system stability and extends mechanical life. Crucially, bearing selection often depends on load type and installation environment. The versatility of double-row angular contact ball bearings makes them the preferred choice for applications requiring high precision and reliability. Leveraging the capabilities of Ningbo Jinxin Bearing Technology Co., Ltd., the company can customize production based on customer drawings to meet these application needs, ensuring seamless integration of bearings into specific industrial environments and helping customers avoid equipment failures and improve production efficiency.

Question 5: What key factors need to be considered when designing or customizing double-row angular contact ball bearings?

Core considerations when designing this type of bearing include contact angle selection, material compatibility, lubrication methods, and sealing performance. The contact angle directly affects load-bearing capacity and needs to be adjusted according to actual operating conditions; material selection relates to wear resistance and corrosion resistance, especially in harsh environments; and lubrication and sealing design are crucial for reducing maintenance needs and extending lifespan. These factors collectively determine the performance boundaries of the bearing. The R&D team at Ningbo Jinxin Bearing Technology Co., Ltd. plays a key role in this process. They can analyze customer-provided samples or drawings, optimize these design parameters, and utilize advanced processes to produce highly adaptable bearings, ensuring that each customized project meets unique technical specifications.

Question 6: Why choose Ningbo Jinxin Bearing Technology Co., Ltd. for the development and production of double-row angular contact ball bearings?

Ningbo Jinxin Bearing Technology Co., Ltd.'s core advantage lies in its strong R&D capabilities, enabling it to provide end-to-end customized services when handling double-row angular contact ball bearings. The company's team is proficient in bearing dynamics principles and can perform reverse engineering and innovative optimization based on customer drawings or samples, ensuring products meet specific performance requirements such as load capacity, speed limits, and durability. This capability not only shortens the development cycle but also reduces customer risk by avoiding the limitations of general-purpose bearings. In actual cooperation, Ningbo Jinxin Bearing Technology Co., Ltd. transforms knowledge and information into actual products through rigorous quality control processes, helping customers maintain a technologically leading position in a highly competitive market.

Question 7: What are the professional considerations for the maintenance and selection strategies of double-row angular contact ball bearings?

Maintaining this type of bearing focuses on regularly checking the lubrication condition, axial preload, and seal integrity to avoid excessive wear. Selection strategies require evaluating load direction, installation space, and environmental conditions—for example, in high-speed applications, the bearing contact angle design must be optimized to reduce vibration. Ningbo Jinxin Bearing Technology Co., Ltd. provides professional support in this field. Its R&D team can interpret customer needs, guide bearing selection and maintenance processes, and ensure long-term performance stability. This combination of expertise makes the company a reliable production partner, helping customers achieve efficient equipment operation.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch