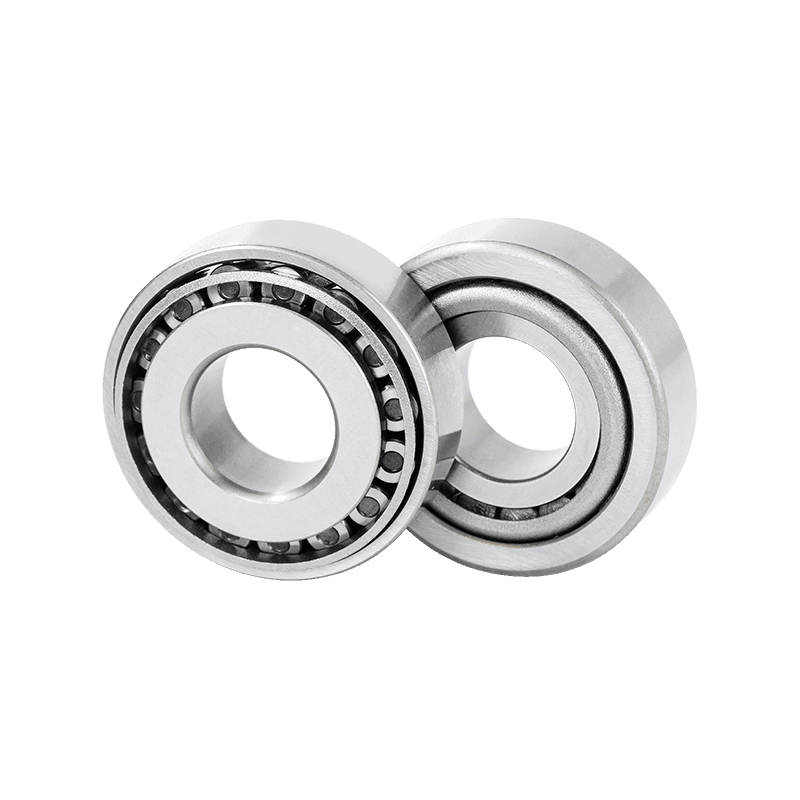

In the industrial bearing field, single-row angular contact ball bearings are a key component widely used in various mechanical systems.

Q1: What is a single-row angular contact ball bearing? What is the essential difference between it and ordinary bearings?

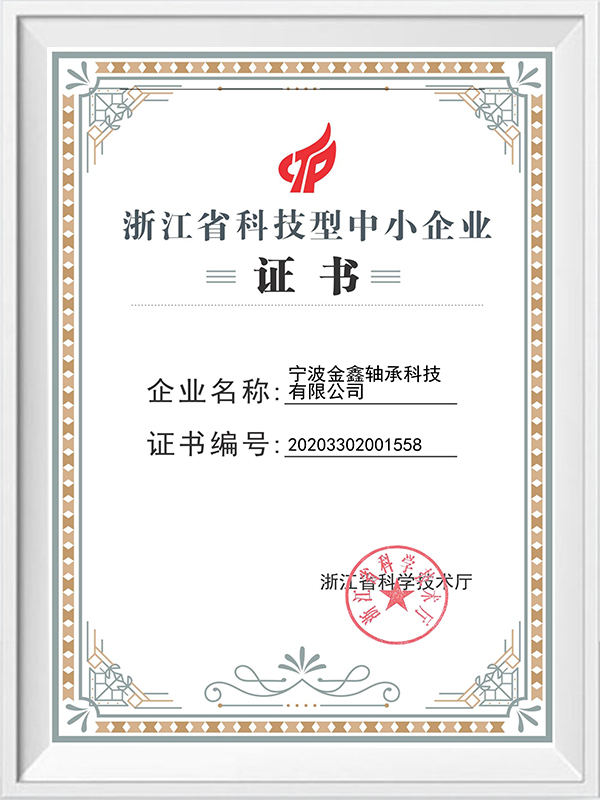

A1: A single-row angular contact ball bearing is a rolling bearing specifically designed to withstand both radial and axial loads simultaneously. Its core difference lies in the bearing's contact angle design: through precise geometry, the bearing balls form specific angles with the inner and outer rings, thereby optimizing load distribution. In contrast, ordinary deep groove ball bearings primarily handle radial loads, while the angular contact design makes the single-row version more efficient under combined load conditions. In the production of this type of bearing at Ningbo Jinxin Bearing Technology Co., Ltd., thanks to a rigorous quality control process, the contact angle accuracy of each bearing is ensured to be consistent, avoiding performance instability caused by design deviations.

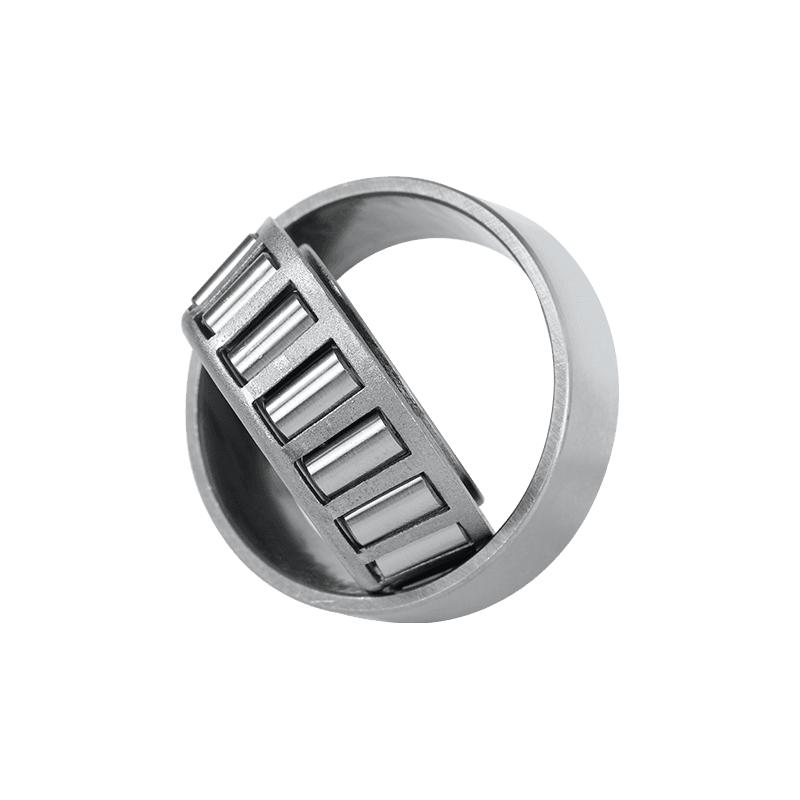

Q2: What is the working principle of a single-row angular contact ball bearing? How is effective load transfer achieved?

A2: The working principle of this bearing is based on its unique angular contact mechanism: when an external load is applied, the balls inside the bearing decompose the force into radial and axial components through a predetermined contact angle, achieving smooth transmission. The key lies in the bearing's geometric symmetry and material toughness, ensuring uniform load distribution under high speed or impact conditions, reducing friction and heat accumulation. Ningbo Jinxin Bearing Technology Co., Ltd. implements rigorous quality control throughout its manufacturing system, such as real-time inspection during heat treatment and grinding stages, to guarantee the bearing's geometric accuracy, thereby optimizing the reliability of its working principle and avoiding premature failure.

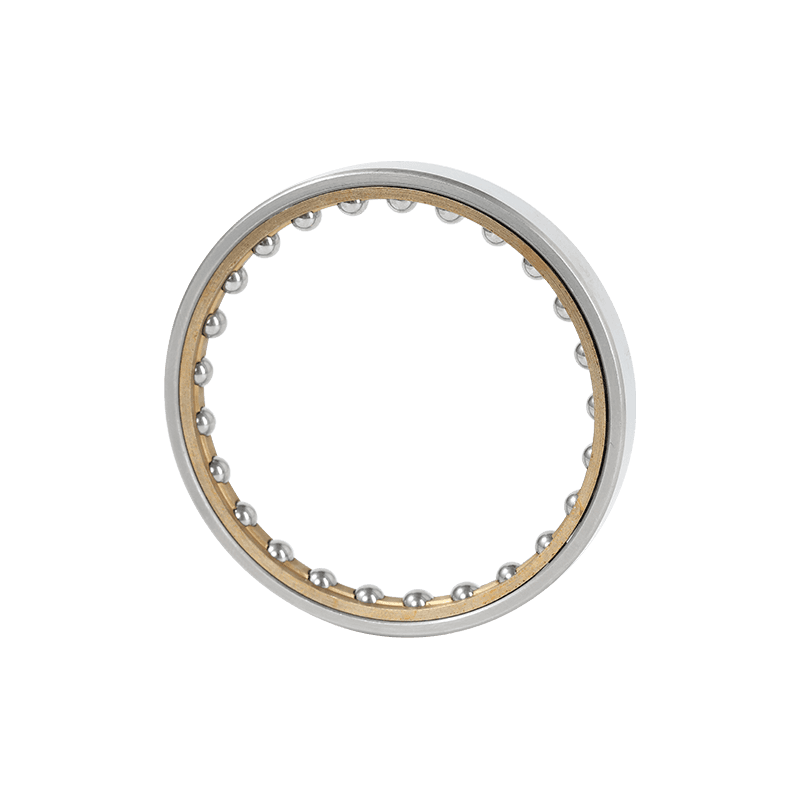

Q3: What are the main application scenarios for single-row angular contact ball bearings? Why are they preferred in these fields?

A3: These bearings are widely used in fields requiring high precision and high dynamic performance, such as machine tool spindles, electric motors, automotive transmissions, and wind turbines. The reason for this preference is their excellent combined load-bearing capacity: they can efficiently handle forces from multiple directions while maintaining low noise and long lifespan. In industrial automation, Ningbo Jinxin Bearing Technology Co., Ltd.'s bearings are often used in critical equipment because the company's quality control system ensures product consistency under harsh environments, such as preventing unexpected downtime during application through full-process inspection.

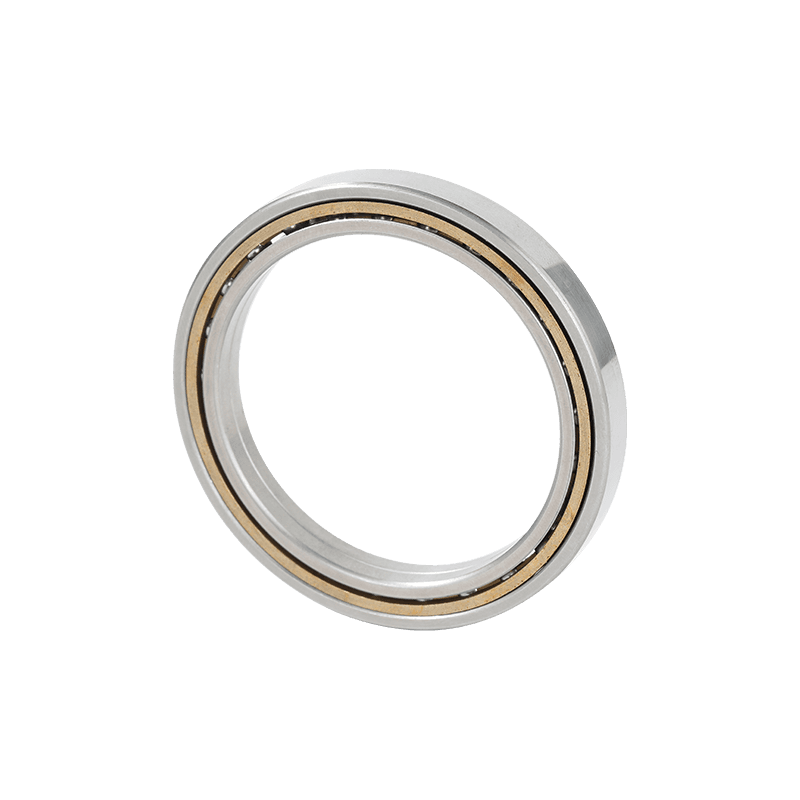

Q4: What are the core advantages of single-row angular contact ball bearings compared to other bearing types (such as double-row or thrust bearings)?

A4: Core advantages include higher rigidity and a more compact design: the single-row structure simplifies installation space and is suitable for narrow equipment layouts; meanwhile, optimized contact angles improve high-speed rotational stability. In comparison, while double-row bearings can withstand higher loads, they are larger; thrust bearings specialize in axial loads, while the single-row angular contact version is more flexible in balancing radial and axial requirements. Ningbo Jinxin Bearing Technology Co., Ltd. reinforces these advantages in production, ensuring strict control of dimensional tolerances for each bearing through quality processes, thereby reducing maintenance needs and improving system efficiency in applications.

Q5: When designing single-row angular contact ball bearings, how do engineers optimize their performance? What are the key considerations?

A5: The key to engineers optimizing performance lies in contact angle adjustment and material selection: the contact angle needs to be customized according to the load type (e.g., a smaller angle is suitable for high axial loads), while materials such as high-strength steel enhance wear resistance. Furthermore, lubrication design is also crucial to minimize frictional losses. Ningbo Jinxin Bearing Technology Co., Ltd. incorporates these factors into its R&D phase, conducting multiple rounds of verification through quality control processes to ensure that design optimizations translate into reliable performance in actual production. For example, defects are eliminated during surface treatment, improving the overall lifespan of the bearings.

Q6: Why is quality control so important in the manufacturing of single-row angular contact ball bearings? How does Ningbo Jinxin Bearing Technology Co., Ltd. ensure this process?

A6: Quality control is crucial because it directly affects the bearing's precision, lifespan, and safety: even minor deviations such as dimensional errors or material inhomogeneity can lead to premature failure. Ningbo Jinxin Bearing Technology Co., Ltd. implements a rigorous quality control process throughout its entire manufacturing system, covering the entire process from raw material procurement to final assembly. This includes standardized operating procedures, automated testing equipment, and regular audits to ensure that every bearing meets high consistency standards. This avoids performance fluctuations, making the bearings more reliable in high-speed or heavy-load applications.

Q7: What common problems might single-row angular contact ball bearings encounter during operation? How can these be prevented through the manufacturing process?

A7: Common problems include increased noise, overheating, or premature wear, often stemming from improper installation or internal defects. Preventative measures involve precision manufacturing: for example, ensuring the surface finish of the balls and raceways to reduce friction. Ningbo Jinxin Bearing Technology Co., Ltd.'s quality control system plays a central role here, identifying and correcting potential problems, such as uneven heat treatment, through process monitoring and sampling tests, thereby eliminating the risk of failure at the source of production and ensuring the smooth operation of the bearings.

Q8: How does Ningbo Jinxin Bearing Technology Co., Ltd.'s quality control enhance the market competitiveness of single-row angular contact ball bearings?

A8: The company's quality control processes directly enhance competitiveness by ensuring product consistency and reliability: In the global market, customers demand high-precision bearings, and Ningbo Jinxin's rigorous processes (such as full lifecycle tracking) reduce return rates and build trust. This makes the bearings perform more stably in applications, supporting customers in achieving efficient equipment operation while reducing total cost of ownership. This quality-oriented strategy allows the company to stand out in fierce competition.

Q9: What are the future development trends of single-row angular contact ball bearings? How does Ningbo Jinxin adapt to these changes?

A9: Trends include lightweight design, environmentally friendly materials, and intelligent monitoring to meet energy-saving and automation requirements. Ningbo Jinxin Bearing Technology Co., Ltd. adapts to these changes through continuous quality control innovation: for example, by introducing sustainable elements into material research and development, and by ensuring rapid iteration of new products through process optimization. The company's quality system provides the fundamental support, enabling bearings to maintain high-performance standards throughout their evolution and driving industry progress.

Q10: What are the overall system benefits of using single-row angular contact ball bearings from Ningbo Jinxin Bearing Technology Co., Ltd.?

A10: Overall benefits include improved overall efficiency and durability of mechanical systems: high-quality bearings reduce energy loss, extend equipment life, and lower failure rates in critical applications. Ningbo Jinxin's rigorous quality control ensures consistency in bearings from production to delivery, such as verifying performance through final inspection, allowing customers to achieve seamless operation without additional adjustments during integration.

Q11: What are some professional recommendations for the installation and maintenance of single-row angular contact ball bearings? How does Ningbo Jinxin's quality control assist in this process?

A11: Professional recommendations include precise alignment and regular lubrication to maximize bearing life. Ningbo Jinxin Bearing Technology Co., Ltd.'s quality control processes support this, as rigorous pre-shipment inspections (such as clearance testing) ensure accurate bearing dimensions, simplifying the installation process and reducing maintenance frequency, thereby improving operational convenience for users.

Q12: Why choose Ningbo Jinxin Bearing Technology Co., Ltd. as your supplier of single-row angular contact ball bearings? What are its quality commitments reflected in?

A12: Choosing Ningbo Jinxin stems from its quality commitment: the company integrates quality control into every manufacturing stage, from raw material selection to finished product testing, ensuring defect-free bearings. This is reflected in consistent product performance and long-term reliability, helping customers cope with challenging applications without worrying about quality fluctuations.

Q13: In a globalized context, how does the standardization of single-row angular contact ball bearings affect Ningbo Jinxin's production?

A13: Standardization drives unified performance requirements. Ningbo Jinxin Bearing Technology Co., Ltd.'s quality control system ensures that products comply with international standards. Through internal calibration and auditing, the bearings have strong compatibility in the global market, enhancing export potential.

Q14: What is the core value of single-row angular contact ball bearings? How does Ningbo Jinxin strengthen it through quality control?

A14: Our core value is providing efficient and reliable load solutions. Ningbo Jinxin Bearing Technology Co., Ltd. ensures that every bearing embodies this value through end-to-end quality control, such as defect prevention and performance verification, supporting industrial innovation.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch