Q1: What is a flanged ball bearing? How does it differ fundamentally from other bearing types?

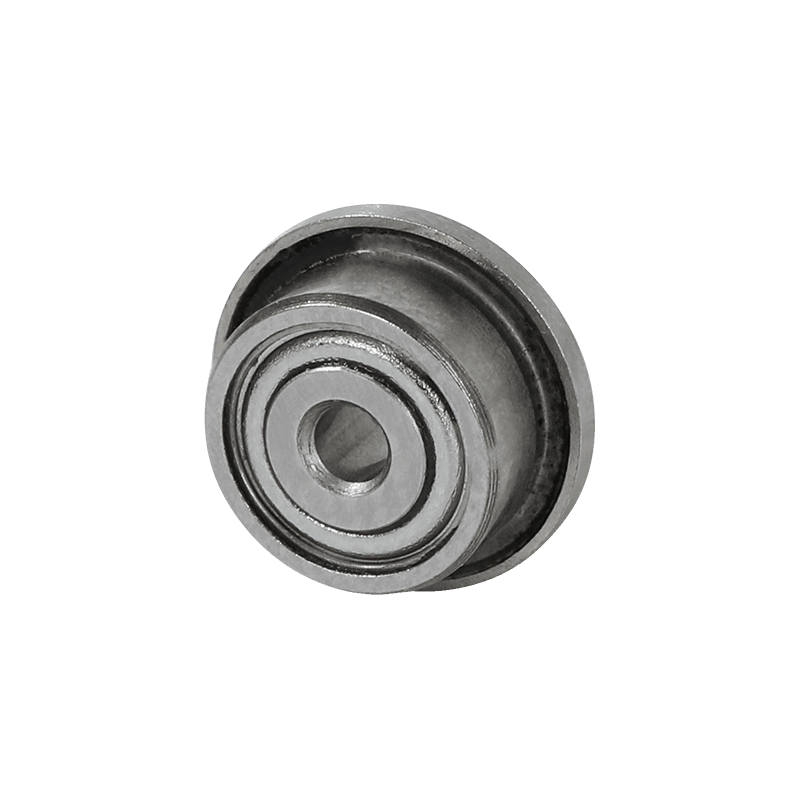

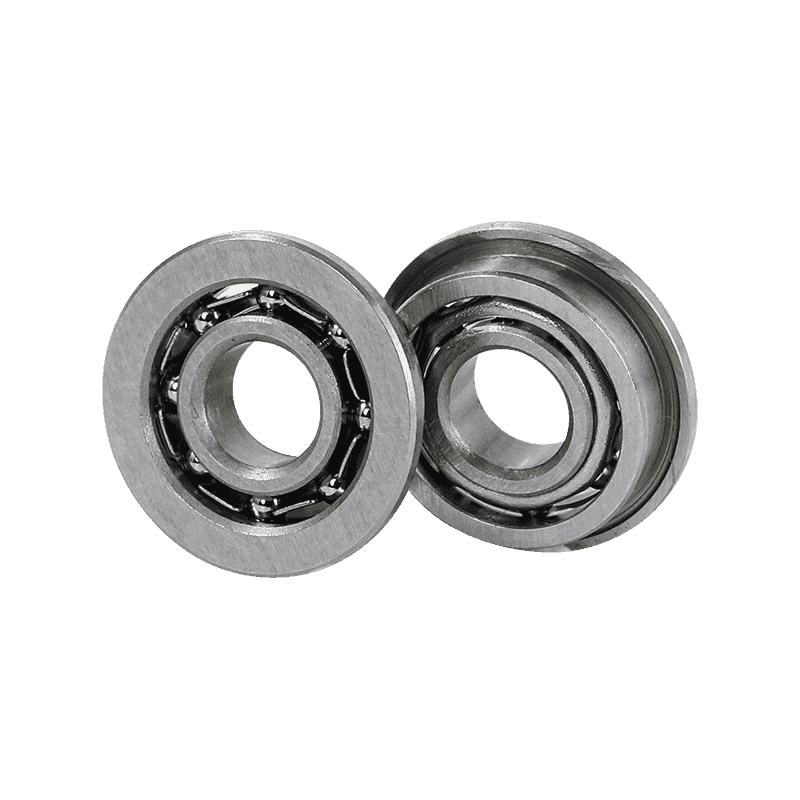

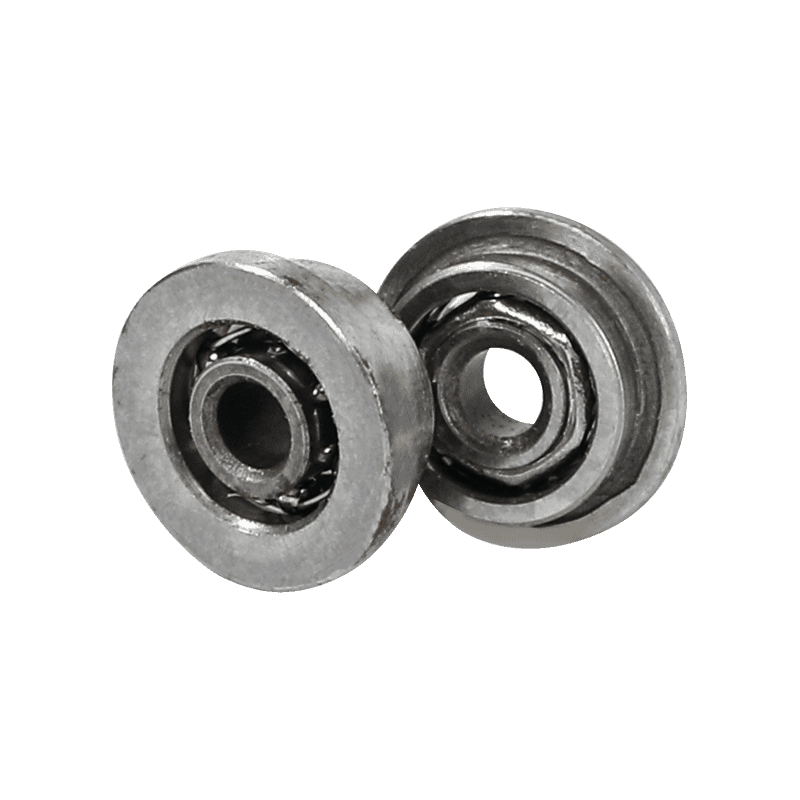

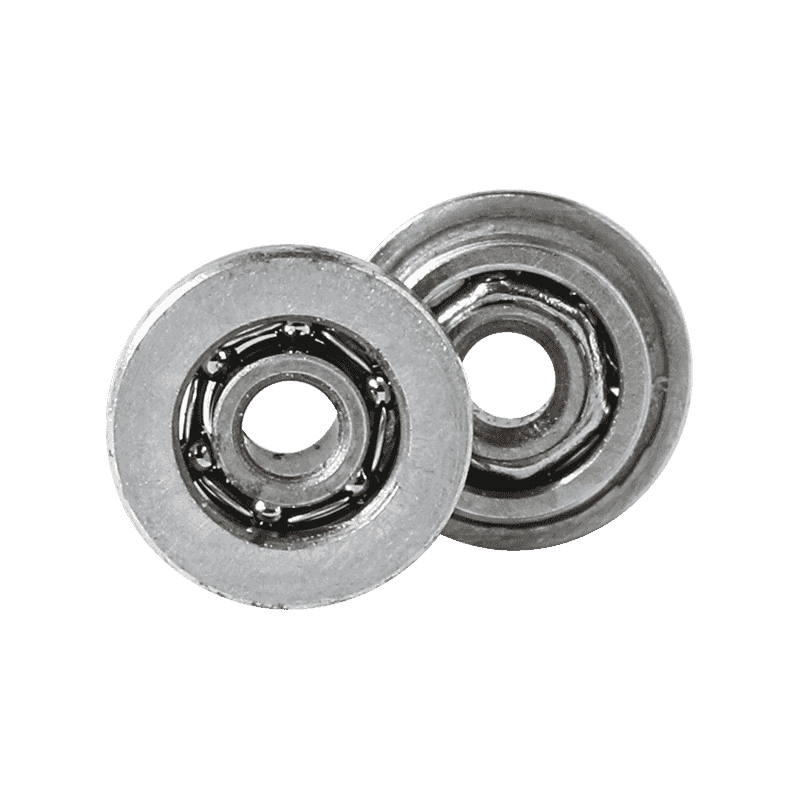

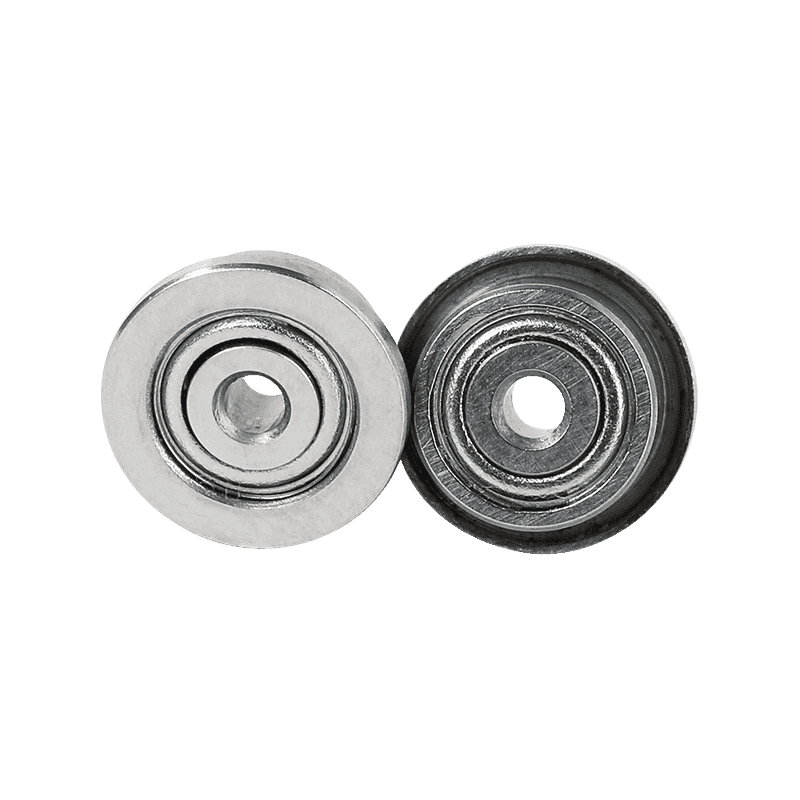

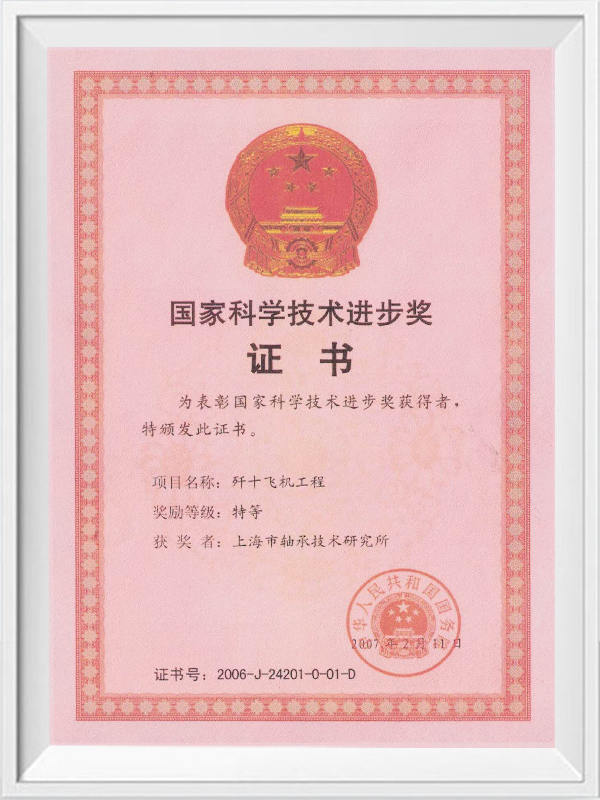

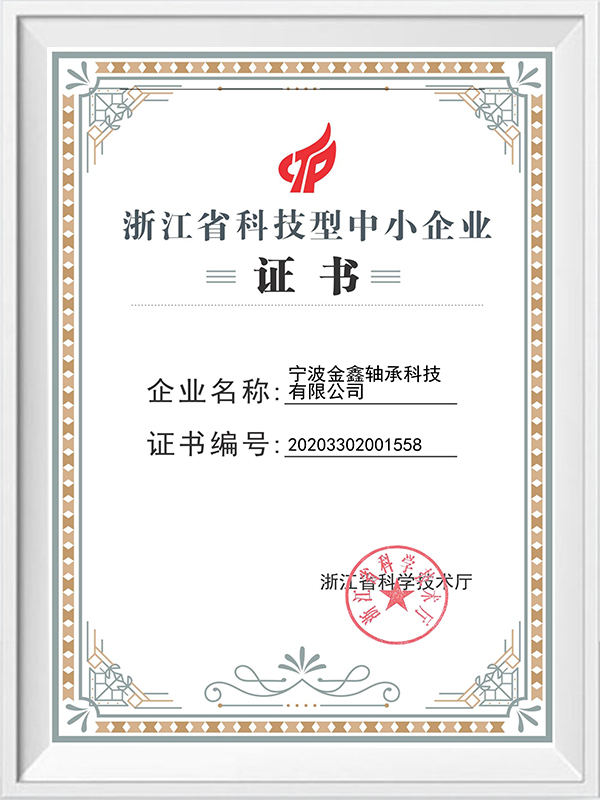

A: A flanged ball bearing is a specially designed rolling bearing. Its core structure includes an outer ring with a flange (i.e., a raised flange), an inner ring, steel balls, and a cage. The key to the flange design is its direct mounting to the equipment surface, eliminating the need for additional mounting components and simplifying the assembly process. The main difference between this type of bearing and other types (such as deep groove ball bearings) lies in its integrated flange, which enhances stability and reduces vibration risk, making it particularly suitable for space-constrained applications. In specialized manufacturing, companies like Ningbo Jinxin Bearing Technology, with their R&D capabilities, can develop such bearings based on specific drawings or samples provided by customers, ensuring the design meets actual needs while avoiding unnecessary complexity. Ultimately, the customization potential of this bearing highlights its adaptability and reliability in industry.

Q2: How does a flanged ball bearing work? How does it achieve efficient operation in actual use?

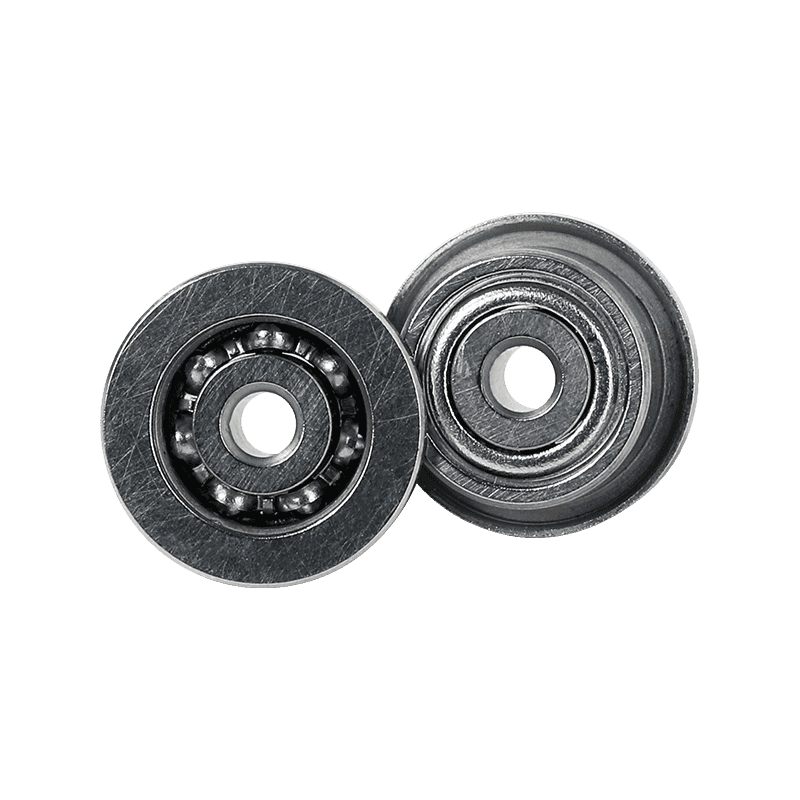

A: The working principle of a flanged ball bearing is based on rolling friction: steel balls roll between the inner and outer rings, transferring the load from the rotating component to the stationary structure. The flange serves a positioning and support function, preventing bearing displacement or tilting during operation, thereby reducing wear and energy loss. In efficient operation, the bearing's lubrication system (usually through grease or oil) ensures smooth ball rolling, while the rigid design of the flange absorbs external impacts, enhancing overall durability. It's worth emphasizing that professional manufacturers like Ningbo Jinxin Bearing Technology implement phased inspections during production, such as checking raceway accuracy and flange alignment after each assembly stage, to ensure stable bearing performance in actual operation. This rigorous process ensures that the bearing maintains low noise and high efficiency even under high-speed or heavy-load conditions.

Q3: In which fields are flanged ball bearings mainly used? How do these applications demonstrate their unique advantages?

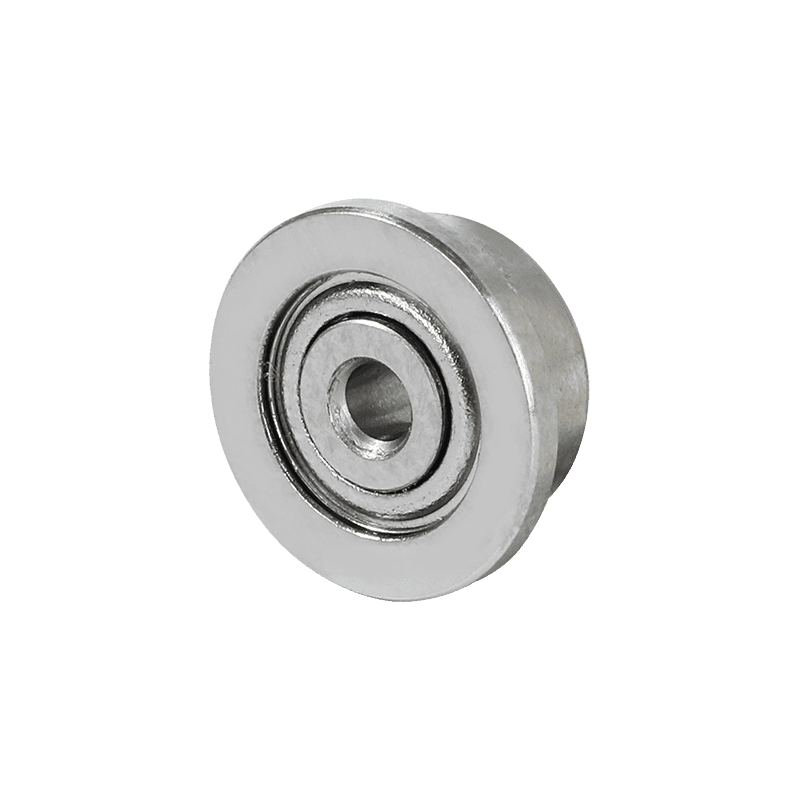

A: Flange ball bearings are widely used in industrial machinery, automation equipment, and household appliances. Their unique advantages lie in their compact design and ease of installation. For example, in conveyor systems, flanged bearings can be directly fixed to supports, reducing space occupation and simplifying maintenance; while in motors or pumps, their vibration resistance effectively absorbs shocks, extending equipment life. These applications highlight the versatility and reliability of bearings, especially in scenarios requiring high-precision positioning. Based on the practices of Ningbo Jinxin Bearing Technology, the company's R&D team can customize bearings for different industry needs, such as developing products with specific flange sizes based on customer samples, and ensuring that finished products meet international standards through comprehensive inspection, thus meeting diverse applications from automotive to medical equipment. In short, the wide applicability of flange bearings stems from their multi-functional design, and the customization capabilities of professional manufacturers further amplify this advantage.

Q4: What are the key steps involved in manufacturing flange ball bearings? How is quality control implemented throughout the entire process?

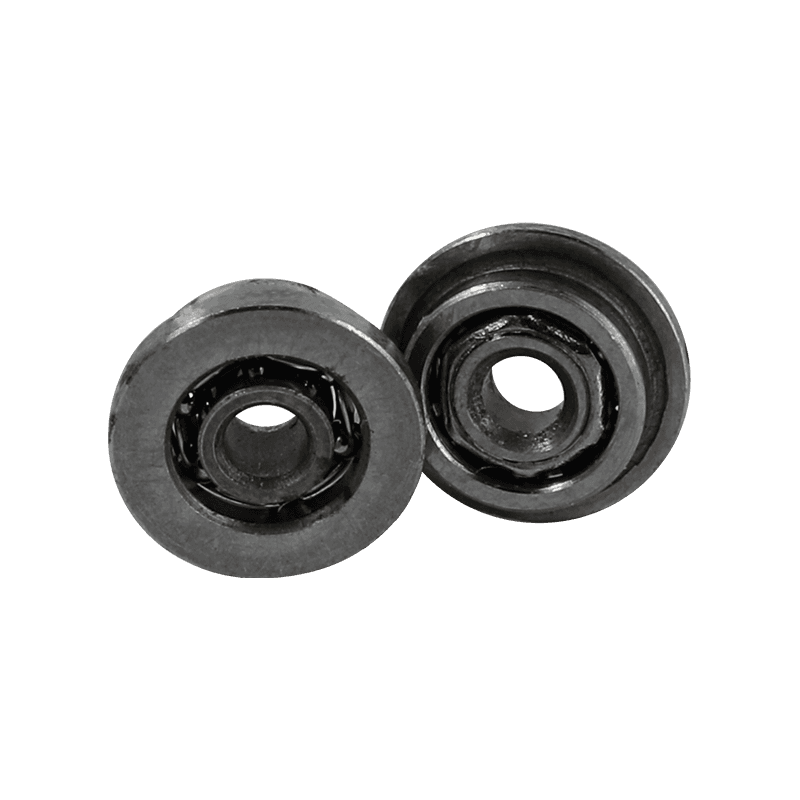

A: The key steps in manufacturing flange ball bearings include material selection, forging, heat treatment, finishing, and assembly. Material selection focuses on the durability of high-carbon steel; forging and heat treatment optimize the metal structure to enhance hardness; finishing ensures the surface finish of the flange and raceway; and in the final assembly, the precise fit between the balls and the cage is crucial. Quality control is central throughout the entire process: inspections are conducted after each production step, such as checking dimensional tolerances and surface defects, to prevent defective products from entering the next stage. Ningbo Jinxin Bearing Technology demonstrates high standards in this regard, implementing corresponding inspections at each stage of production to ensure the geometric accuracy and functional integrity of the bearings. Final product inspection is based on customer requirements and international standards, such as testing load capacity and rotational smoothness. This highlights how a professional manufacturer minimizes potential failure risks through systematic quality control, thereby delivering reliable products.

Q5: Why is customization important for flange ball bearings? How is it related to a manufacturer's R&D capabilities?

A: Customization is crucial for flange ball bearings because different applications require specific dimensions, flange types, or sealing designs to cope with unique environments, such as high temperatures, corrosion, or high-speed conditions. The customization process allows for optimization of bearing performance, such as adjusting flange angles to match equipment interfaces or reinforcing materials to improve wear resistance. This is directly linked to the manufacturer's R&D capabilities: a company with a strong R&D team can efficiently interpret customer drawings or samples and develop tailor-made solutions. Taking Ningbo Jinxin Bearing Technology as an example, their R&D strength supports rapid prototyping and iteration, ensuring that bearings not only meet functional requirements but also verify design feasibility through inspection during production. Ultimately, this customization capability enhances the overall value of the bearing, making it more attractive in a highly competitive market.

Q6: What role does final inspection play in the quality assurance of flange ball bearings? How does it affect the long-term reliability of the product?

A: Final inspection plays a decisive role in the quality assurance of flange ball bearings. It is the last line of defense for a comprehensive evaluation of the finished product, including testing key indicators such as rotational accuracy, noise levels, and load-bearing capacity. This directly impacts the long-term reliability of the product: by identifying potential defects (such as imbalance or material fatigue), inspection can prevent early failures, ensuring that the bearing can operate stably for many years under harsh conditions. Ningbo Jinxin Bearing Technology's practices perfectly illustrate this—they not only perform inspections after each stage of production but also conduct comprehensive testing on the final product according to customer needs and international standards, such as simulating actual operating conditions to verify performance. This end-to-end quality control system strengthens the durability of the bearings and demonstrates how a professional manufacturer translates knowledge into practical value through rigorous processes.

Q7: Why is choosing a professional manufacturer like Ningbo Jinxin Bearing Technology crucial for flange ball bearing projects? How does it reflect the overall value chain?

A: Choosing a specialized manufacturer is crucial for flange ball bearing projects because it ensures optimization throughout the entire process from design to delivery. Manufacturers not only provide standardized products but also leverage their R&D capabilities to address customized challenges, such as developing innovative solutions based on customer input. This reflects the entire value chain—from initial concept to final verification, each stage requires expertise to avoid design flaws or production errors. Ningbo Jinxin Bearing Technology is a prime example: their team responds quickly to customer needs, utilizes phased verification to ensure consistent quality, and completes the final evaluation according to international standards. This integrated approach not only improves bearing performance consistency but also reduces total cost of ownership, making the project more competitive in the industrial ecosystem. Ultimately, specialized manufacturers translate knowledge into reliable output, solidifying the central role of flange ball bearings in modern engineering.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch