In the industrial sector, bearings, as core components of mechanical equipment, directly impact the efficiency and reliability of the overall system. Non-standard custom bearings, as a highly personalized solution, are gaining increasing attention. Ningbo Jinxin Bearing Technology Co., Ltd., a company deeply rooted in the bearing industry, is always customer-oriented, adhering to the principles of quality first and reputation paramount, and committed to meeting diverse application scenarios through technological innovation.

1. What are non-standard custom bearings? Why are they so important in modern industry?

Non-standard custom bearings, as the name suggests, refer to bearing products that do not follow general standard dimensions or specifications, but are designed and manufactured according to the specific needs of customers. Their importance stems from the complexity of industrial applications: different equipment varies significantly in operating conditions, load requirements, or environmental factors, and standard bearings often cannot fully adapt. For example, in high-temperature, high-speed, or corrosive environments, general-purpose bearings may be at risk of failure, while custom solutions can precisely match these challenges. Ningbo Jinxin Bearing Technology Co., Ltd. emphasizes this by deeply understanding the potential needs of customers, transforming the customization process into a preventative solution: not simply providing products, but building a customer-centric engineering dialogue. This allows companies to avoid the limitations of a "one-size-fits-all" approach and ensure that bearings perform at their maximum efficiency in critical applications.

2. In which application scenarios are non-standard customized bearings necessary? How do they meet the specific working conditions of customers?

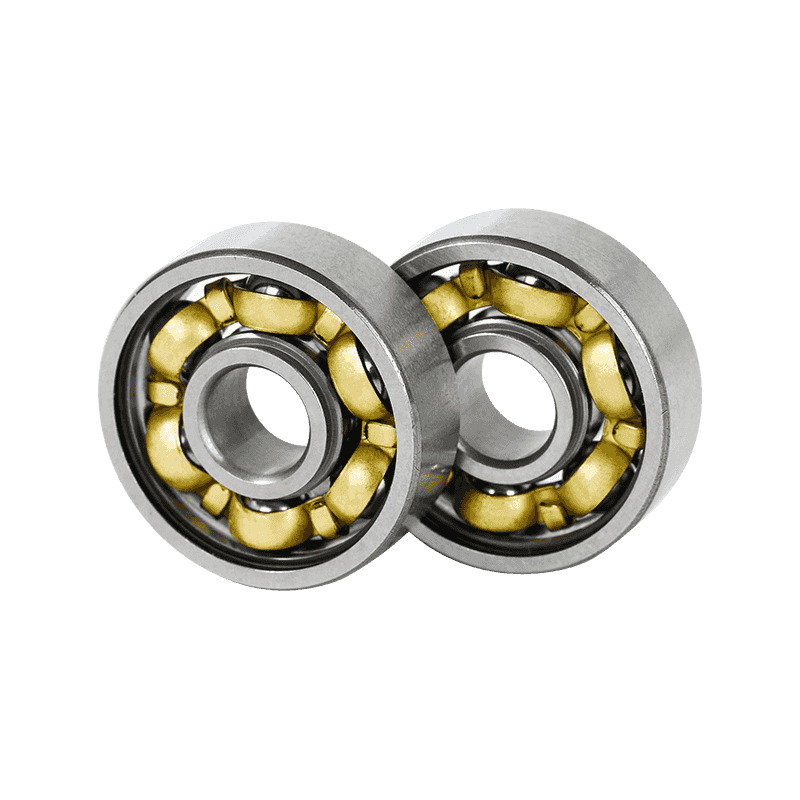

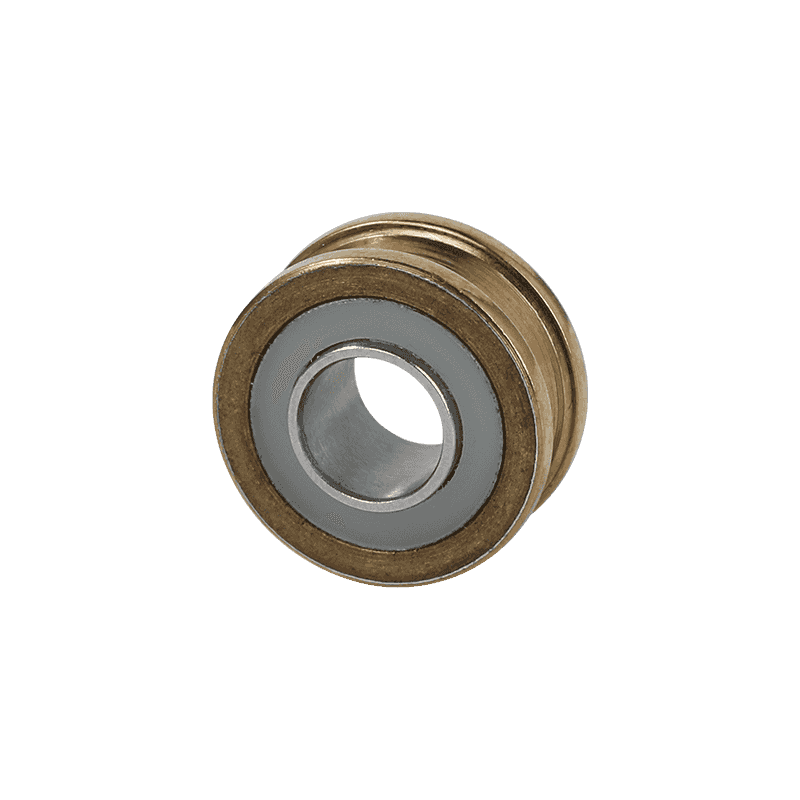

Non-standard customized bearings have a wide range of applications, mainly concentrated in areas that standard products cannot cover. For example, in special mechanical devices, such as precision instruments, medical devices, or aerospace equipment, working conditions often involve extreme temperatures, high speeds, or irregular loads, requiring bearings with unique material selection, structural optimization, or lubrication design. Ningbo Jinxin Bearing Technology Co., Ltd. adheres to the principle of "customer-centricity" when handling such needs: First, it understands the equipment's operating environment, potential failure points, and performance targets through professional consultation; second, it uses technological innovation to adjust the internal structure of the bearing, such as optimizing raceway design or enhancing sealing performance, thereby ensuring stable operation under specific working conditions. This customization process is not only a technical adjustment but also a deep response to the customer's actual working conditions, helping companies solve the fundamental problem of "why standard bearings fail."

3. How do non-standard customized bearings bring faster speeds, lower noise, and a more comfortable user experience?

One of the core advantages of customized bearings lies in their ability to significantly improve the overall performance of equipment, including speed, noise control, and user experience. This stems from meticulous adjustments during the design phase: for example, by optimizing the bearing's geometry and material composition, frictional losses can be reduced, resulting in more stable speeds at high speeds; simultaneously, to address noise issues, customized solutions can introduce vibration-damping structures or special coatings to effectively absorb vibration energy and reduce operating noise. Ningbo Jinxin Bearing Technology Co., Ltd., in pursuing these goals, adheres to the philosophy of "quality first": every customized project is controlled from the source, ensuring material purity and manufacturing precision to avoid performance degradation due to minor defects. Ultimately, this not only improves equipment efficiency but also allows users to experience a smoother and quieter experience in daily operation, reflecting the core value of "a more comfortable user experience."

4. How does Ningbo Jinxin Bearing Technology Co., Ltd. achieve the development of non-standard customized bearings through technological innovation? What role does technological innovation play in this process?

Technological innovation is the key driving force for the success of non-standard customized bearings, involving optimization across the entire chain from design to production. In the practice of Ningbo Jinxin Bearing Technology Co., Ltd., technological innovation is reflected on multiple levels: First, advanced simulation tools are used for virtual testing to predict bearing behavior under specific operating conditions, reducing the cost of physical trial and error; second, new materials or surface treatment technologies are developed to address challenges such as corrosion and wear. The company adheres to the principle of "reputation first," ensuring that every innovation stems from a genuine understanding of customer needs: for example, when customers face high-temperature environments, the technical team explores the application of heat-resistant alloys rather than relying on off-the-shelf solutions. This innovation process emphasizes a "problem-oriented" approach, meaning that technology is not isolated but serves to solve practical pain points and help customers overcome performance bottlenecks.

5. How is quality and integrity ensured in the production of custom bearings? How is Ningbo Jinxin Bearing Technology Co., Ltd.'s mission reflected in this?

Quality and integrity are the cornerstones of custom bearings, relating to product reliability and long-term cooperation. In the production process, this involves strict process control: from raw material procurement to final inspection, every step must ensure compliance with design specifications to avoid functional deviations caused by accumulated tolerances. Ningbo Jinxin Bearing Technology Co., Ltd. adheres to the principle of "quality as the foundation and integrity as the cornerstone," integrating this philosophy into its daily operations. On the one hand, it establishes a transparent communication mechanism, allowing customers to participate in the entire design review process to ensure that customized solutions truly reflect their needs. On the other hand, through its internal quality system, it eliminates any compromises, maintaining product consistency and durability. This practice of integrity not only reduces after-sales issues but also builds lasting customer trust—as the company advocates, every collaboration is a verification of its "reputation first" commitment.

6. For potential customers, how to evaluate and select service providers for non-standard customized bearings? How does Ningbo Jinxin Bearing Technology Co., Ltd.'s customer-oriented principle play a role?

When choosing a suitable customized bearing service provider, customers should focus on the company's comprehensive capabilities, including technical strength, responsiveness, and value alignment. Ningbo Jinxin Bearing Technology Co., Ltd. provides a reference framework through its customer-oriented principle: First, the company emphasizes "understanding the customer's potential needs," meaning that in the initial consultation phase, the team will conduct in-depth analysis of the equipment background rather than rushing to sell solutions; second, based on "customer-centric" interaction, it focuses on balancing feasibility and cost-effectiveness when providing customized suggestions. This principle helps clients avoid the risks of "blindly customizing": for example, when evaluating suppliers, clients can examine whether they truly value long-term relationships rather than short-term transactions. Ningbo Jinxin Bearing Technology Co., Ltd.'s enthusiastic attitude—welcoming new and old friends to consult and discuss—is a reflection of this philosophy, encouraging open dialogue and the co-creation of efficient solutions.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch