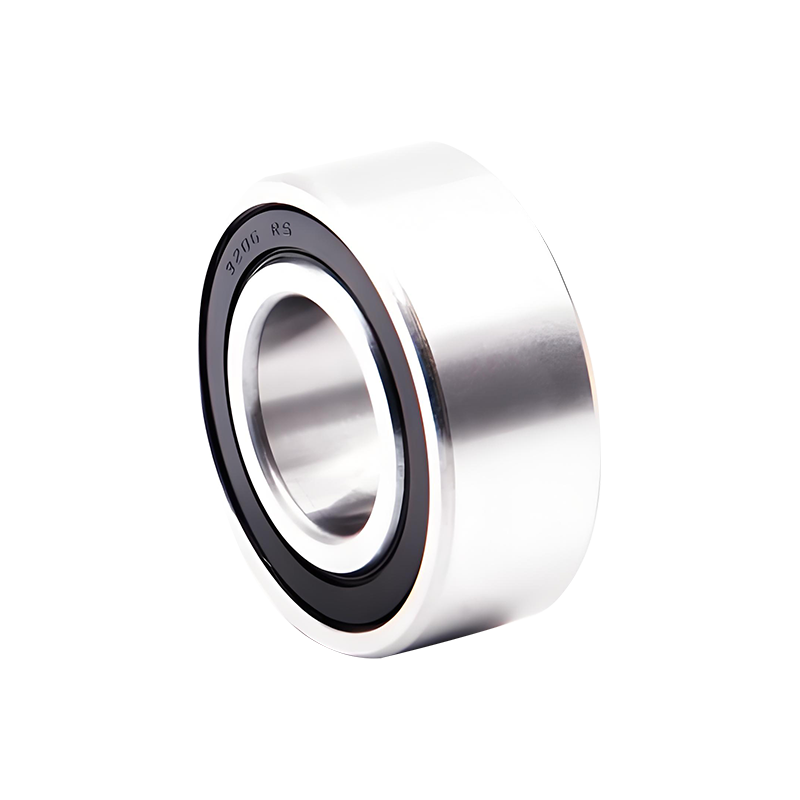

In the bearing industry, double-row deep groove ball bearings are a key component, attracting significant attention due to their unique design and wide applicability. Ningbo Jinxin Bearing Technology Co., Ltd., always prioritizing customer needs, is committed to optimizing bearing performance to meet diverse operating conditions through technological innovation and quality assurance.

What is a double-row deep groove ball bearing? What are the fundamental differences between it and a single-row version?

A double-row deep groove ball bearing is a bearing structure with two rows of balls between the inner and outer rings, designed to increase overall load-bearing capacity by increasing the number of balls. In contrast, a single-row deep groove ball bearing has only one row of balls. Therefore, the double-row design better distributes loads, enhancing bearing rigidity and stability. Ningbo Jinxin Bearing Technology Co., Ltd. focuses on understanding customers' potential needs for high-load operating conditions during research and development. Through precise design and material selection, they ensure that bearings maintain stable performance under high-speed operation, thereby reducing the risk of equipment failure.

Why are double-row deep groove ball bearings preferred in certain applications? What are their main advantages?

The main advantages of double-row deep groove ball bearings lie in their excellent radial and axial load-carrying capacity and higher rigidity, making them particularly suitable for space-constrained but demanding environments. For example, in industrial machinery or automotive transmission systems, the double-row design effectively absorbs vibration and shock, extending equipment life. Ningbo Jinxin Bearing Technology Co., Ltd., based on quality and reputation, optimizes the internal structure of bearings through innovative processes, thereby reducing noise while improving operating efficiency, meeting customers' pursuit of a "more comfortable user experience."

In which industries or equipment are double-row deep groove ball bearings commonly used? How do they adapt to different operating conditions?

These bearings are widely used in motors, pumps, gearboxes, and precision instruments, performing exceptionally well in high-speed or heavy-load scenarios. Their adaptability stems from design flexibility, enabling them to cope with complex operating conditions such as high temperature, high humidity, or polluted environments. Ningbo Jinxin Bearing Technology Co., Ltd., through continuous technological innovation, such as optimizing raceway geometry and lubrication systems, helps bearings achieve "faster speeds" and "lower noise" under varying conditions, ensuring smooth and reliable equipment operation.

How can technological innovation improve the performance of double-row deep groove ball bearings? What unique approaches does Ningbo Jinxin Bearing Technology Co., Ltd. take in this regard?

Technological innovation includes material upgrades, surface treatments, and optimized thermal management to enhance the wear resistance and fatigue resistance of bearings. Ningbo Jinxin Bearing Technology Co., Ltd. focuses on developing customized solutions, such as using advanced simulation technology to predict bearing behavior under different operating conditions, thereby optimizing the design in advance. This approach not only improves the overall efficiency of bearings but also achieves energy-saving goals by reducing frictional losses, directly responding to customers' needs for a "more comfortable user experience."

How does the design of double-row deep groove ball bearings contribute to the pursuit of faster speeds and lower noise? How does Ningbo Jinxin ensure these performance characteristics?

Double-row deep groove ball bearings significantly reduce operating noise and increase speed limits through optimized ball arrangement and clearance control, thanks to reduced internal friction and vibration. During the manufacturing process, Ningbo Jinxin Bearing Technology Co., Ltd. strictly adheres to a quality control system, combined with high-precision machining technology, to ensure the balance and consistency of each bearing. This commitment to "quality and reputation" ensures that the bearings remain quiet and stable during high-speed operation, helping customers' equipment achieve superior performance.

What role do quality and reputation play in bearing manufacturing? How does Ningbo Jinxin integrate this concept into the production of double-row deep groove ball bearings?

Quality and reputation are the cornerstones of bearing reliability, directly impacting equipment lifespan and user safety. Ningbo Jinxin Bearing Technology Co., Ltd. ensures defect-free bearing delivery by establishing a full-process monitoring system, from raw material selection to finished product testing. Simultaneously, the company values customer feedback and continuously iterates designs to meet specific operating conditions, demonstrating its commitment to a "customer-centric" approach. This focus not only improves the overall durability of double-row deep groove ball bearings but also strengthens the brand's credibility in the industry.

What are the future development trends of double-row deep groove ball bearings? How does Ningbo Jinxin address these challenges through innovation?

With the rise of industrial automation and green manufacturing, bearings are evolving towards higher efficiency and environmental friendliness, such as integrating intelligent monitoring functions or using sustainable materials. Ningbo Jinxin Bearing Technology Co., Ltd. actively embraces technological innovation, driving bearings to achieve higher performance under extreme conditions through the development of new coatings and vibration reduction technologies. This forward-thinking approach aims to help customers meet the challenges of future operating conditions while delivering on the vision of "faster speeds, lower noise, and a more comfortable user experience."

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch