Single-row deep groove ball bearings are a fundamental and widely used type of bearing in mechanical engineering. They are renowned for their simple structure and high reliability, and are suitable for various rotating equipment. Ningbo Jinxin Bearing Technology Co., Ltd., as a professional manufacturer certified by the IATF 16949 international quality system, consistently integrates high standards into bearing design and production.

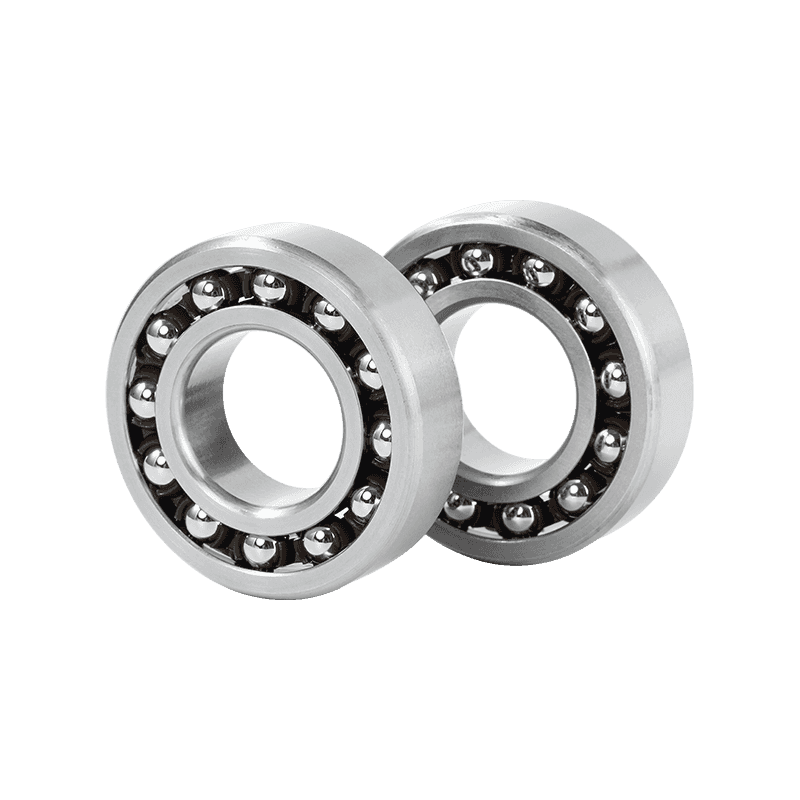

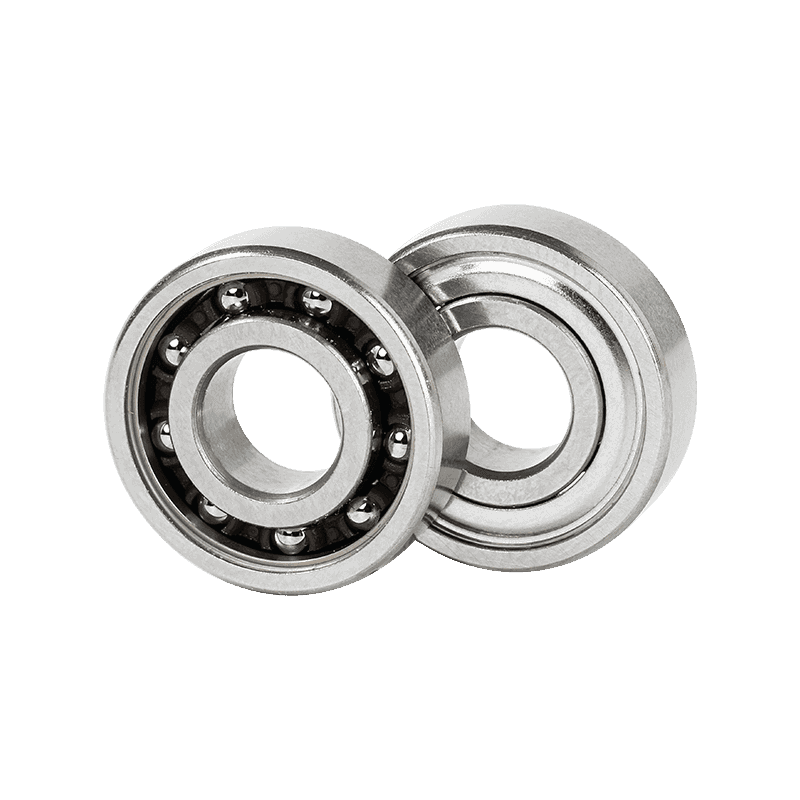

Q: What is the basic structure and working principle of a single-row deep groove ball bearing?

A: A single-row deep groove ball bearing consists of an inner ring, an outer ring, steel balls, and a cage. Both the inner and outer rings have deep grooves, within which the steel balls roll, forming continuous contact points. This design allows the bearing to withstand both radial and axial loads simultaneously, achieving smooth rotation. The working principle is based on rolling friction: the steel balls roll between the inner and outer rings, reducing friction loss and improving efficiency. Ningbo Jinxin Bearing Technology Co., Ltd. strictly adheres to the IATF 16949 standard during manufacturing, ensuring the geometric accuracy and surface finish of each component, thereby optimizing the bearing's dynamic performance. This helps extend service life and reduce the risk of equipment failure.

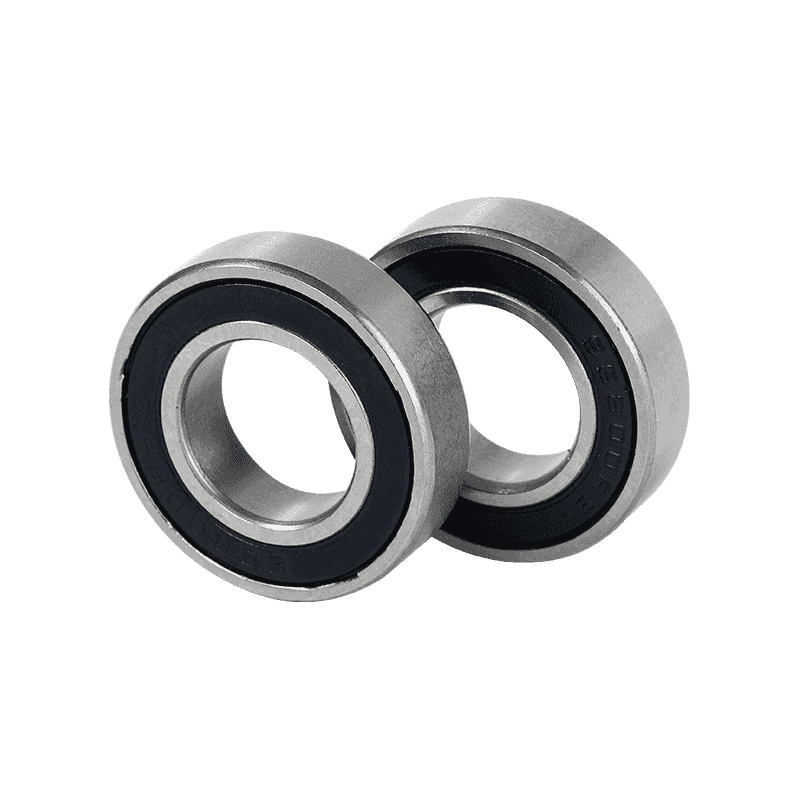

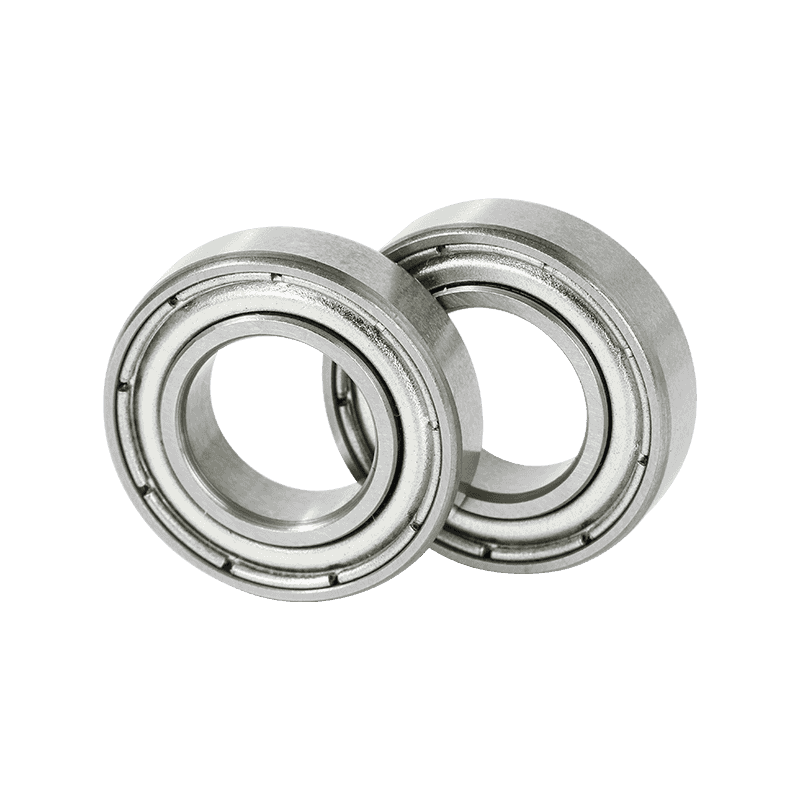

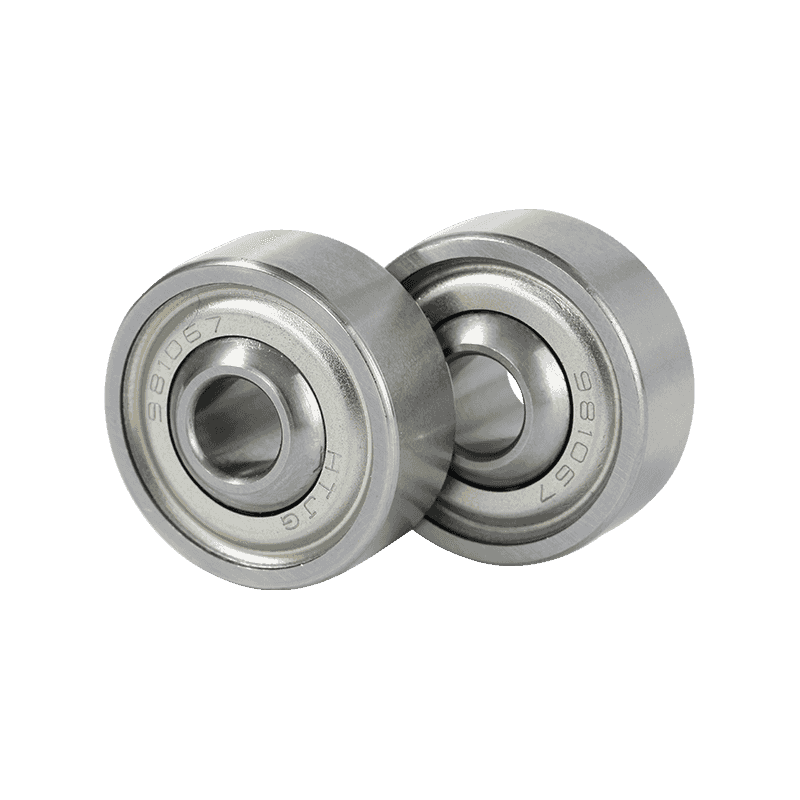

Q: What are the unique design advantages of single-row deep groove ball bearings?

A: Its core advantages lie in its high load-bearing capacity and low maintenance requirements. In terms of design, the deep groove structure provides uniform load distribution, avoiding localized stress concentration; simultaneously, sealed or dustproof designs prevent contaminant intrusion. These features ensure bearing stability at high speeds, reducing energy consumption. Ningbo Jinxin Bearing Technology Co., Ltd., certified by IATF 16949, emphasizes systematic control of the design process. For example, in material selection and heat treatment, the company employs advanced processes to ensure a balance between bearing hardness and toughness, thereby improving overall durability. This professional manufacturing approach ensures consistent performance even in harsh environments.

Q: What role do single-row deep groove ball bearings play in industrial applications?

A: These bearings are widely used in rotating equipment such as motors, pumps, fans, and automotive components. They effectively handle combined radial and axial loads and are suitable for applications requiring high precision and low noise. In automated production lines or vehicle transmission systems, the reliability of single-row deep groove ball bearings is crucial. Ningbo Jinxin Bearing Technology Co., Ltd., with its IATF 16949 certification, emphasizes risk assessment for application scenarios. For example, in the automotive industry, companies ensure bearings meet performance requirements under high-speed, high-temperature conditions through rigorous quality control. This demonstrates how certification systems drive bearing adaptability in complex applications.

Q: Why do single-row deep groove ball bearings require high-quality manufacturing standards?

A: High-quality manufacturing standards are crucial for ensuring bearing performance and safety. Manufacturing deviations can lead to vibration, noise, or premature failure, impacting overall equipment efficiency. IATF 16949 certification emphasizes process control and continuous improvement, including monitoring from raw material procurement to finished product testing. Ningbo Jinxin Bearing Technology Co., Ltd. has established a preventative quality system through this certification. For example, during the bearing assembly stage, the company implements precision measurements and functional tests to eliminate potential defects. This professional approach not only improves bearing precision but also enhances its resilience under harsh conditions, meeting the reliability needs of industrial users.

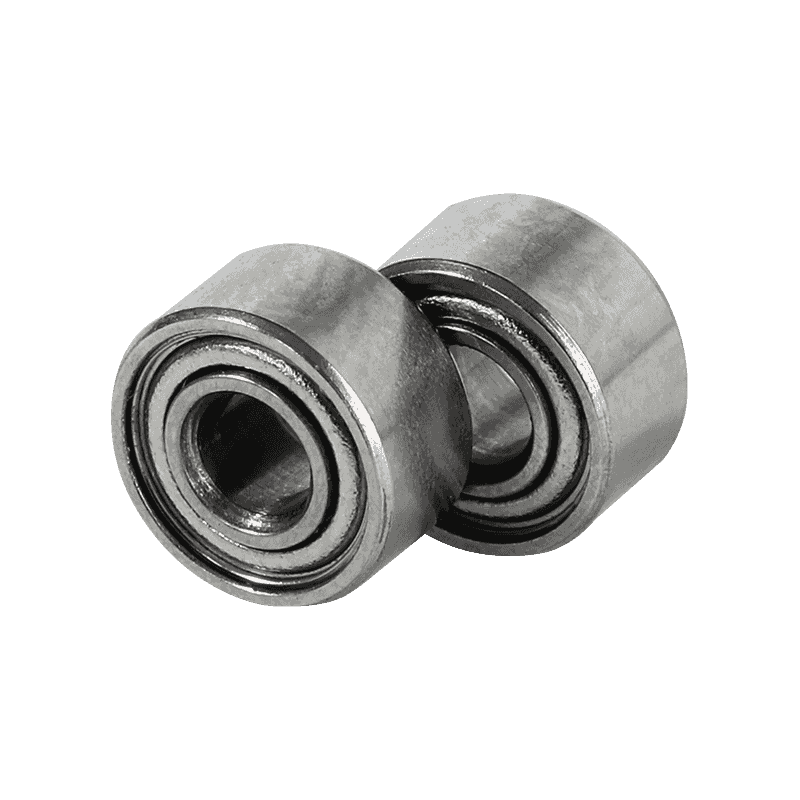

Q: How to evaluate and select suitable single-row deep groove ball bearings?

A: The selection process considers load type, speed, and environmental factors. For example, high-load applications require optimized ball size and groove depth; corrosive environments necessitate special coatings or seals. Engineers need to conduct dynamic analysis based on equipment requirements to avoid overload or failure. Ningbo Jinxin Bearing Technology Co., Ltd. provides technical support services under the IATF 16949 framework. The company helps customers identify key parameters, such as bearing fatigue life prediction, through the data-driven approach of the certification system. This professional guidance ensures accurate selection and reduces engineering risks.

Q: How can the maintenance and lifespan of single-row deep groove ball bearings be optimized?

A: Optimized maintenance involves regular lubrication and condition monitoring. Lubricants reduce friction and wear, extending lifespan; monitoring vibration or temperature changes allows for early detection of problems. Furthermore, the installation accuracy of the bearing directly affects performance, such as the fit tolerances between the shaft and housing bore. Ningbo Jinxin Bearing Technology Co., Ltd., certified by IATF 16949, strengthens its maintenance strategies. The company emphasizes preventative maintenance training, such as pre-setting lubrication channels during manufacturing for easy on-site maintenance. This stems from the certification system's requirement for customer support, ensuring bearings maintain efficient operation throughout their lifespan.

Q: How does Ningbo Jinxin Bearing Technology Co., Ltd.'s professional background influence the manufacturing of single-row deep groove ball bearings?

A: As an IATF 16949 certified company, Ningbo Jinxin Bearing Technology Co., Ltd. integrates international quality standards into every aspect of bearing production. This certification, geared towards the automotive industry, requires a zero-defect target, which directly improves the reliability and consistency of bearings. For example, in the material handling stage, the company employs advanced surface strengthening technology to enhance wear resistance; in the testing stage, performance is verified by simulating actual working conditions. This professional manufacturing not only meets industry specifications but also ensures the performance of single-row deep groove ball bearings in high-speed, high-load applications. Ultimately, users benefit from longer service life and reduced operating costs.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch