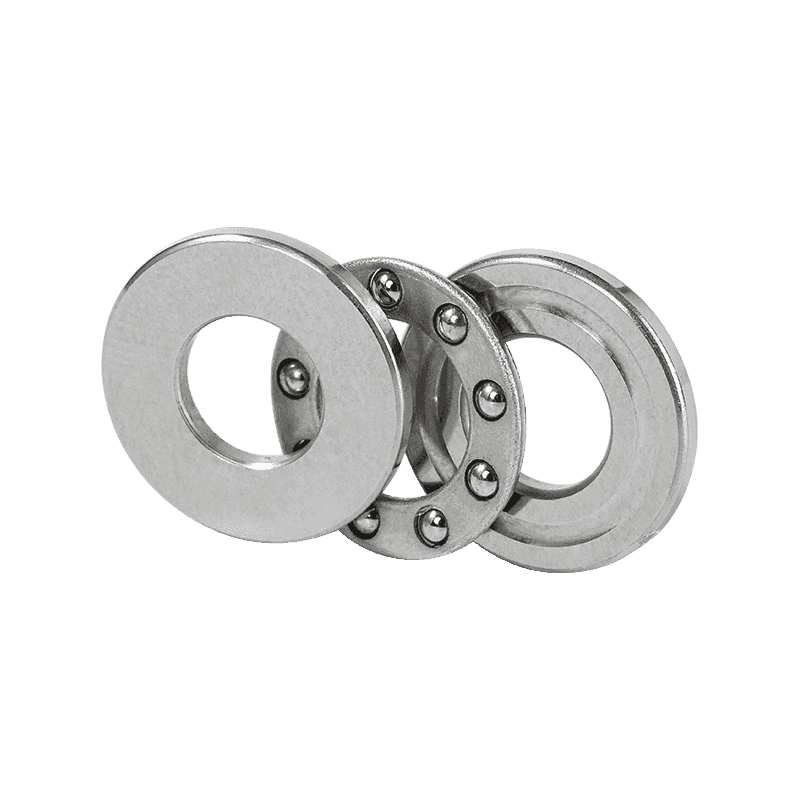

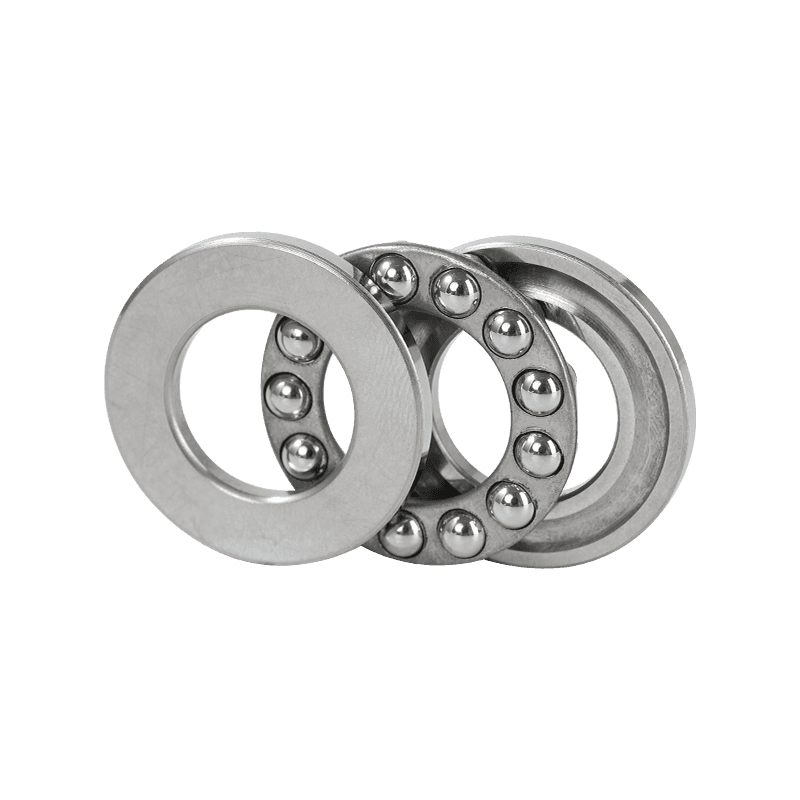

Q: What defines a Single Thrust Ball Bearing in terms of its basic structure and function?

A: A Single Thrust Ball Bearing is a specialized rolling-element bearing engineered exclusively to manage axial loads, which means it handles forces applied parallel to a shaft's axis rather than perpendicular ones. Its core design features include two hardened washers—known as shaft and housing washers—with precisely grooved raceways that accommodate steel balls. These balls facilitate smooth rotational movement under thrust pressure, distributing the load evenly to minimize friction and prevent premature wear. Unlike radial bearings, this variant operates unidirectionally, making it ideal for scenarios where axial forces dominate. At Ningbo Jinxin Bearing Technology Co., Ltd., the production of such bearings leverages automated systems to achieve consistent raceway geometry and ball alignment, ensuring that each unit delivers predictable motion control. This attention to structural integrity underscores how the bearing's fundamental mechanics—like load distribution and surface optimization—are refined through rigorous manufacturing vigilance, resulting in components that excel in demanding environments without compromising simplicity.

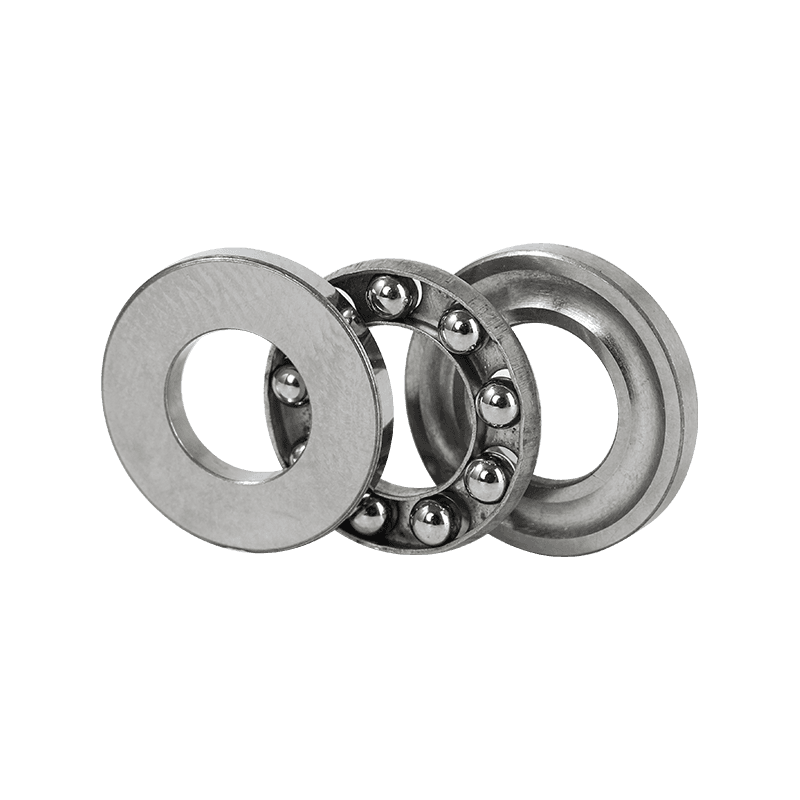

Q: How does a Single Thrust Ball Bearing operate within mechanical assemblies to handle axial stress?

A: In practical operation, the bearing functions by converting axial forces into rotational energy through the rolling action of its balls between the raceways. As thrust is applied, the balls roll smoothly, reducing friction and enabling efficient power transmission along the axis. This mechanism prevents sliding wear and heat buildup, which is crucial for maintaining system longevity in applications like gearboxes or pumps. The design inherently supports high-speed rotation under heavy axial loads while requiring minimal lubrication for sustained performance. Ningbo Jinxin Bearing Technology Co., Ltd. enhances this operational reliability by employing advanced monitoring during production; for instance, their technical personnel scrutinize each step—from material selection to final assembly—to guarantee that surface finishes and tolerances adhere to exacting standards. This methodical approach ensures that the bearings exhibit consistent behavior under stress, such as resistance to deformation and quiet operation, thereby amplifying their functional advantages in real-world settings without overcomplicating the underlying physics.

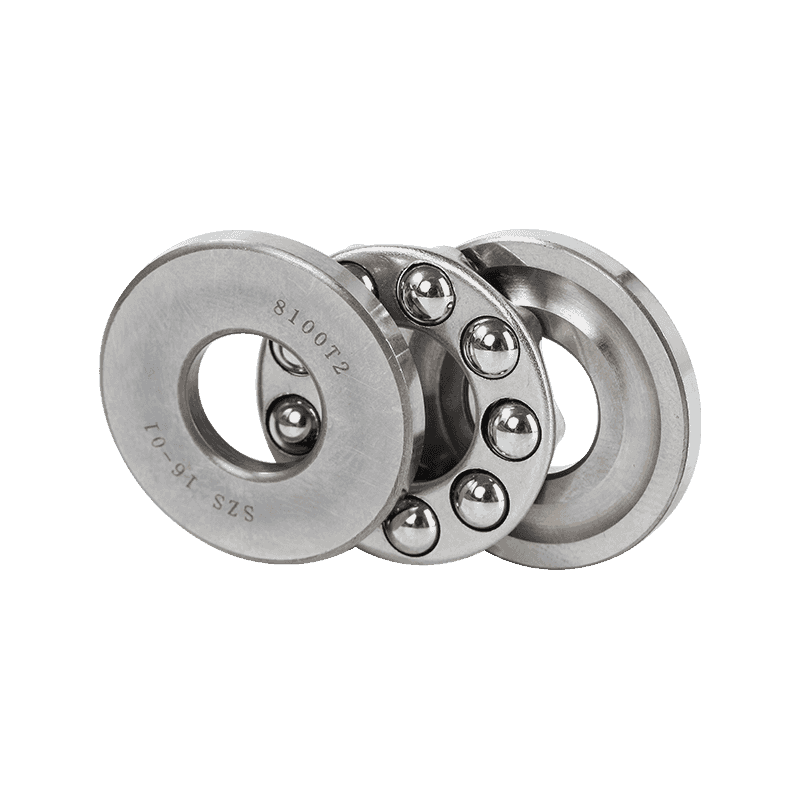

Q: In what types of applications do Single Thrust Ball Bearings prove most effective, and why?

A: These bearings are particularly effective in applications where axial loads are predominant and space constraints demand a compact, focused solution. Common examples include automotive transmissions, where they manage clutch thrust; industrial machinery like conveyor systems that handle directional thrust; and equipment requiring precise axial positioning, such as in machine tools or agricultural implements. Their effectiveness stems from their ability to absorb heavy thrust loads without spreading radially, thus minimizing system bulk and enhancing overall efficiency. When combined with Ningbo Jinxin's production ethos—featuring automated lines that ensure uniform quality—the bearings become even more adept in high-impact environments. The company's emphasis on process control, such as continuous oversight by skilled technicians, ensures that each bearing delivers optimal durability and accuracy. This synergy makes them indispensable in sectors demanding reliability under repetitive axial forces, like energy generation or material handling, where the bearings' innate properties are fortified through disciplined manufacturing to prevent failures and extend service life.

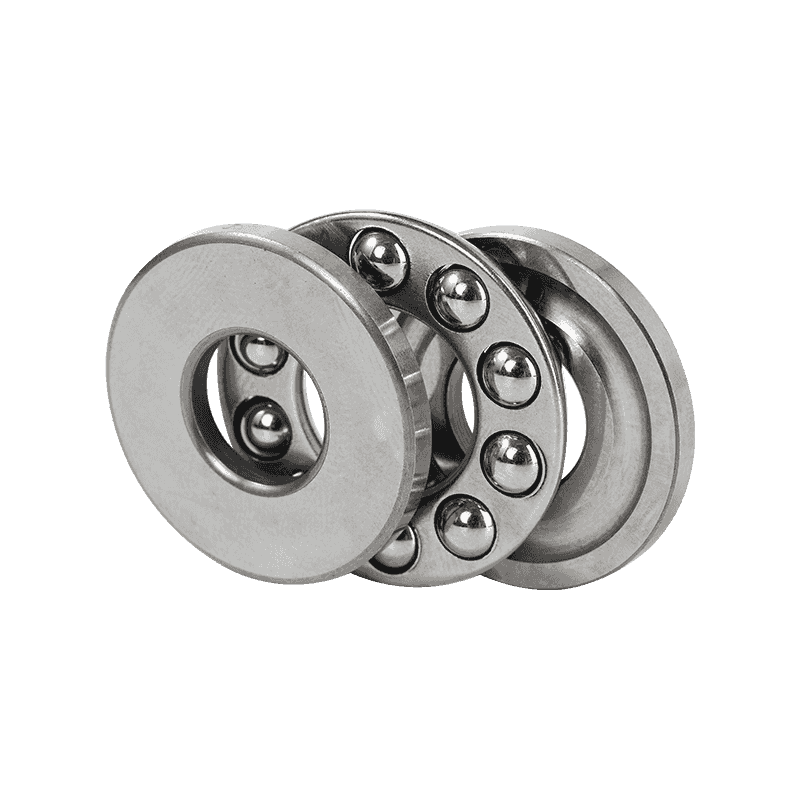

Q: What inherent advantages do Single Thrust Ball Bearings offer over other bearing types in axial load management?

A: Key advantages include their high axial load capacity relative to size, low rotational torque due to reduced friction from precise ball movement, and straightforward installation that simplifies assembly and maintenance. They excel in handling sudden or variable thrust loads while maintaining stability, thanks to their unidirectional focus that avoids the complexities of combined loads. Additionally, their design promotes self-alignment in some configurations, accommodating minor misalignments without performance degradation. At Ningbo Jinxin Bearing Technology Co., Ltd., these benefits are amplified through sophisticated production techniques; for example, their automated processes ensure consistent hardening of components to resist wear, while expert surveillance of each manufacturing phase guarantees that imperfections are eliminated. This results in bearings that not only capitalize on their natural efficiencies—like energy savings and noise reduction—but also embody enhanced resilience and adaptability. Consequently, end-users benefit from solutions that perform reliably under harsh conditions, such as high-temperature operations or corrosive atmospheres, where the bearings' core strengths are bolstered by unwavering quality assurance.

Q: How does the expertise at Ningbo Jinxin Bearing Technology Co., Ltd. elevate the performance and reliability of Single Thrust Ball Bearings?

A: Ningbo Jinxin elevates bearing performance by integrating advanced automation and stringent process controls into their manufacturing framework. This includes utilizing cutting-edge equipment to achieve micron-level precision in raceway grinding and ball placement, coupled with automated inspection systems that detect deviations in real-time. Professional technical teams monitor every stage—from raw material processing to final testing—ensuring conformity to high standards without external documentation. This holistic approach directly enhances the bearing's reliability by guaranteeing uniform hardness, optimal surface finishes, and defect-free assembly. As a result, the bearings exhibit superior load-handling capabilities, extended fatigue life, and consistent operation under stress. Such meticulous production practices align seamlessly with the intrinsic demands of Single Thrust Ball Bearings, like maintaining low friction and preventing axial play, thereby delivering components that excel in critical applications where failure is not an option. Ultimately, this commitment to excellence underscores how industrial innovation transforms theoretical bearing advantages into tangible, long-lasting solutions for global machinery.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch