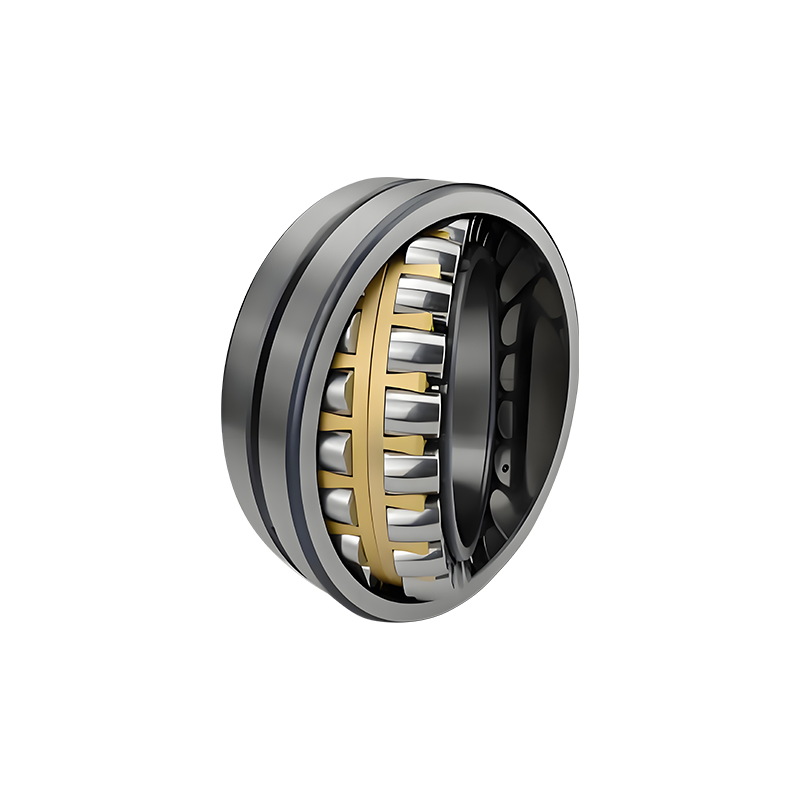

In the field of precision mechanical transmission, angular contact bearings play a crucial role. Their unique design and performance enable them to withstand many demanding operating conditions. As a professional enterprise deeply rooted in the bearing manufacturing industry, Ningbo Jinxin Bearing Technology Co., Ltd.'s technical team frequently engages in in-depth discussions and practical applications of the core technologies of angular contact bearings.

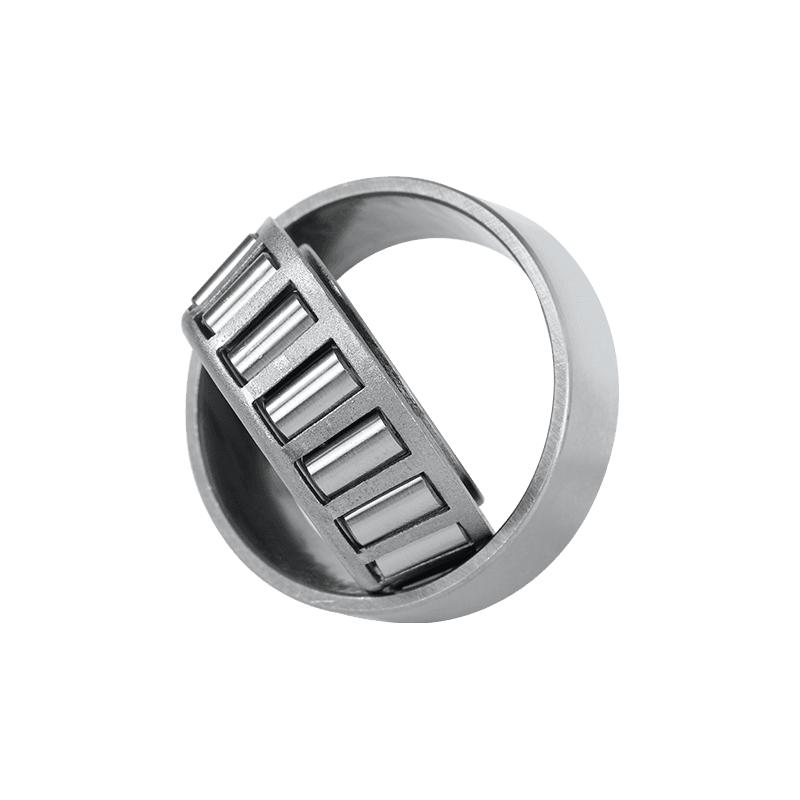

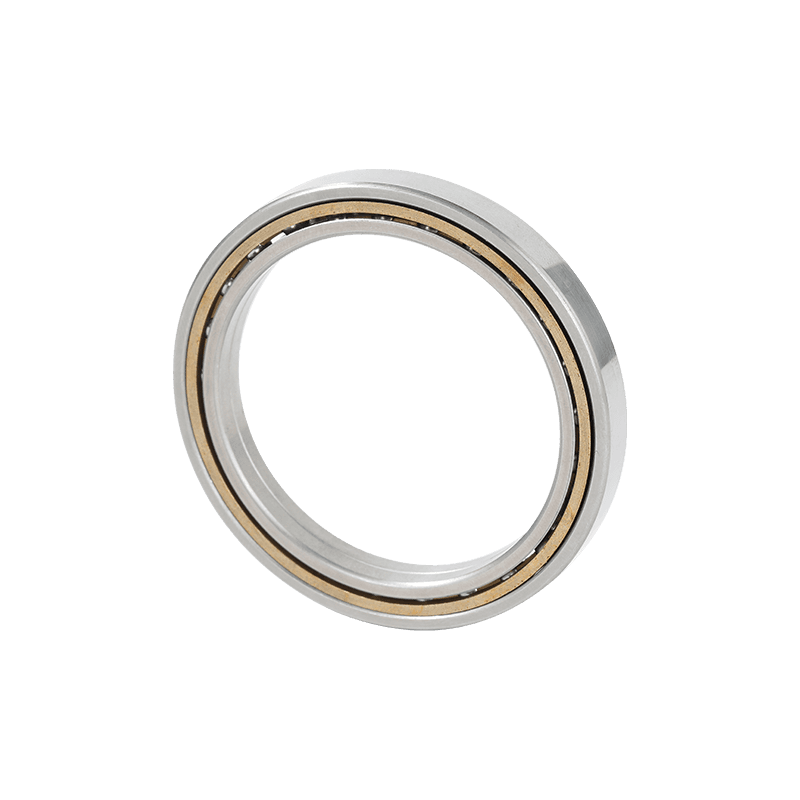

1. Q: What are the core structural features of angular contact bearings? How do they differ from deep groove ball bearings?

* A: The most significant feature of angular contact bearings is the specific contact angle in their inner and outer raceway design. This contact angle is not zero (as in deep groove ball bearings), but rather designed at a certain angle. This allows the bearing to effectively and necessaryly withstand unidirectional axial loads while bearing radial loads. Its raceway profile is precisely calculated to ensure that the rolling elements (steel balls) transmit loads at a specific angle within the raceway, thereby optimizing the bearing's performance under combined loads (radial and axial combinations). During the manufacturing process, Ningbo Jinxin Bearing Technology Co., Ltd. strictly controls the precision of raceway curvature, groove position, and contact angle to ensure that each bearing meets its design mechanical characteristics.

2. Q: What is the decisive influence of contact angle on the performance of angular contact bearings?

* A: Contact angle is a key design parameter of angular contact bearings, directly defining the bearing's load-carrying characteristics and stiffness. Generally, the larger the contact angle (commonly 25°, 30°, 40°), the stronger the bearing's axial load-bearing capacity and the higher its axial stiffness; while a smaller contact angle (such as 15°) can better adapt to higher speed requirements while maintaining a certain axial load-carrying capacity. Choosing the appropriate contact angle requires comprehensive consideration of the main load direction in the application (radial or axial), the required stiffness level, and speed limitations. Ningbo Jinxin engineers will focus on analyzing these factors when assisting customers with model selection and recommend the most suitable contact angle specification.

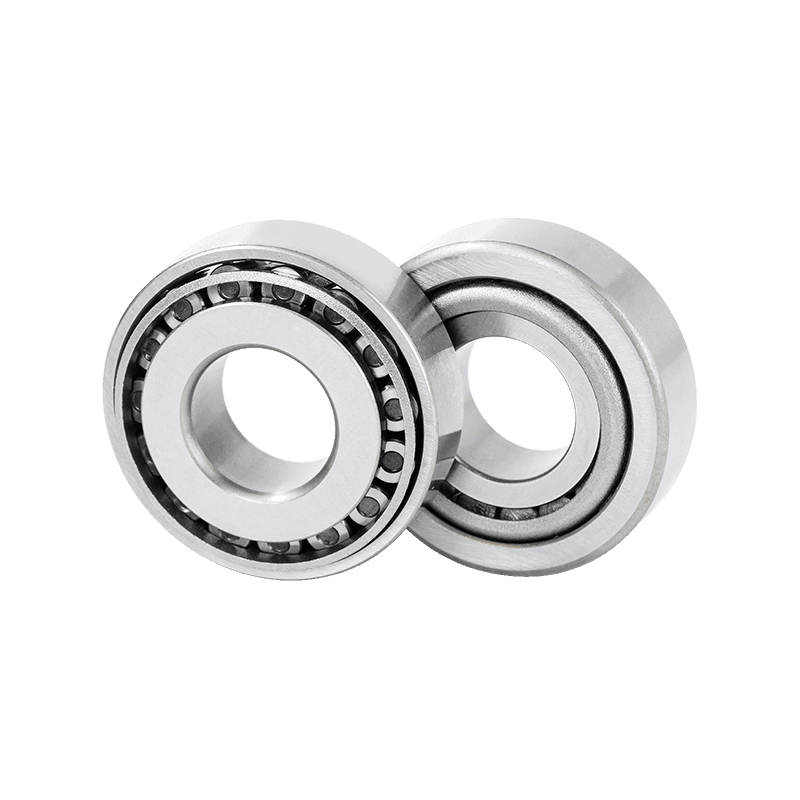

3. Q: Why are angular contact bearings usually installed in pairs? What are some common pairing configurations?

* A: Because angular contact bearings are designed to primarily bear unidirectional axial loads, when there are bidirectional axial loads in the application or when higher system stiffness and stability are required, two or more bearings are usually installed in pairs. Common pairing configurations include:

* Back-to-back (DB): The wide end faces of the bearing outer rings face each other. This configuration provides high moment stiffness and good shaft bending compensation, suitable for applications requiring high rigidity and resistance to overturning moments.

* Face-to-face (DF): The narrow end faces of the bearing outer rings face each other. This configuration has slightly better self-aligning capability than back-to-back, but its resistance to overturning moments is relatively weaker.

* Tandem (DT): Bearings are arranged in the same direction. This configuration is mainly used when very large unidirectional axial loads need to be borne, distributing the load across multiple bearings.

Ningbo Jinxin Bearing Technology Co., Ltd. not only provides single angular contact bearings, but also has professional paired bearing supply capabilities. We can provide pre-adjusted clearance and preload paired bearing sets according to the operating conditions and rigidity requirements of customer equipment, ensuring the operating accuracy and stability of the equipment spindle.

4. Q: What role does preload play in angular contact ball bearing applications? How is it applied and selected?

* A: Preload is a key means of optimizing the performance of angular contact bearings (especially when used in pairs). The main purposes of applying preload are:

* Eliminating internal clearance: Improving bearing rigidity and rotational accuracy, reducing displacement and vibration during operation.

* Preventing ball slippage: Under high-speed, light-load conditions, preload ensures stable rolling of the balls within the raceway.

* Extending life (moderate preload): Proper preload optimizes load distribution among the rolling elements.

Preload methods mainly include positioning preload (achieving a fixed preload amount through precise control of the bearing end face distance) and constant pressure preload (providing constant pressure through springs, etc.). Choosing the right preload is a delicate art of balance: too little preload is ineffective; too much leads to a surge in frictional heat generation, accelerated wear, and a sharp reduction in lifespan. Ningbo Jinxin's technical support emphasizes that rigorous calculations and experimental verification must be performed based on bearing dimensions, speed, load, and desired rigidity requirements.

5. Question: What are the special requirements for installation accuracy of angular contact bearings?

* A: angular contact bearings require extremely high geometric accuracy from the mounting base, including:

* Dimensional and form tolerances of the shaft and bearing housing: Roundness and cylindricity must be strictly controlled.

* Perpendicularity/coaxiality of mating surfaces: The bearing housing bore shoulder and shaft shoulder must maintain high perpendicularity to the axis to ensure no misalignment after the bearing is installed.

* Coaxiality of mating installations: For mating bearing assemblies, the locating surfaces of the two bearing housings must be on the same axis to avoid generating harmful additional loads.

Any installation deviation will lead to uneven load distribution within the bearing, creating additional stress concentration points, significantly reducing bearing life, and increasing vibration and noise. Ningbo Jinxin Bearing Technology Co., Ltd. understands this and conducts rigorous geometric accuracy testing on its products before leaving the factory. We also advise customers to follow high-precision assembly processes during installation and can provide professional installation guidance when necessary.

6. Q: In which key application areas are angular contact bearings mainly suitable?

* A: Due to their superior high-speed performance, high precision, and ability to withstand combined loads, angular contact bearings have become the preferred choice for many demanding applications:

* Machine tool spindles: Require extremely high rotational accuracy, rigidity, and temperature rise control.

* Gearboxes (especially high-speed gearboxes): Bear the radial and axial forces generated by gear meshing.

* Pumps (such as multistage centrifugal pumps): Bear the axial thrust generated by the impeller.

* Gearboxes (high-speed end): Bear the load on the input shaft.

* Motors (especially high-speed motors): Support the rotor and withstand possible axial magnetic pull.

* Precision instruments and testing equipment: Require low vibration and high operational smoothness.

Ningbo Jinxin Bearing Technology Co., Ltd.'s products are widely used in these high-end industrial fields. Its "quality first" principle is reflected in its commitment to the reliability of every angular contact ball bearing used in critical equipment.

7. Q: What key factors need to be considered when selecting angular contact ball bearing materials?

* A: Materials are the fundamental guarantee of bearing performance. Key considerations include:

* High strength and toughness: To withstand alternating contact stress.

* High hardness and wear resistance: To resist rolling contact fatigue and wear.

* Dimensional stability: To maintain accuracy during long-term operation or temperature variations.

* Purity and uniformity: To reduce early failure caused by material defects.

For general applications, high-carbon chromium bearing steel is typically selected, with toughness enhanced through special heat treatment processes (such as bainitic hardening) to meet higher impact or low-temperature requirements. For applications requiring higher corrosion resistance, high-temperature resistance, or special operating conditions, stainless steel bearing steel or high-temperature bearing steel will be considered. Ningbo Jinxin Bearing Technology Co., Ltd. rigorously selects raw material suppliers, implements scientific material inspection standards, and employs advanced heat treatment processes to ensure that material performance meets or even exceeds standard requirements, laying the foundation for long-life bearing operation.

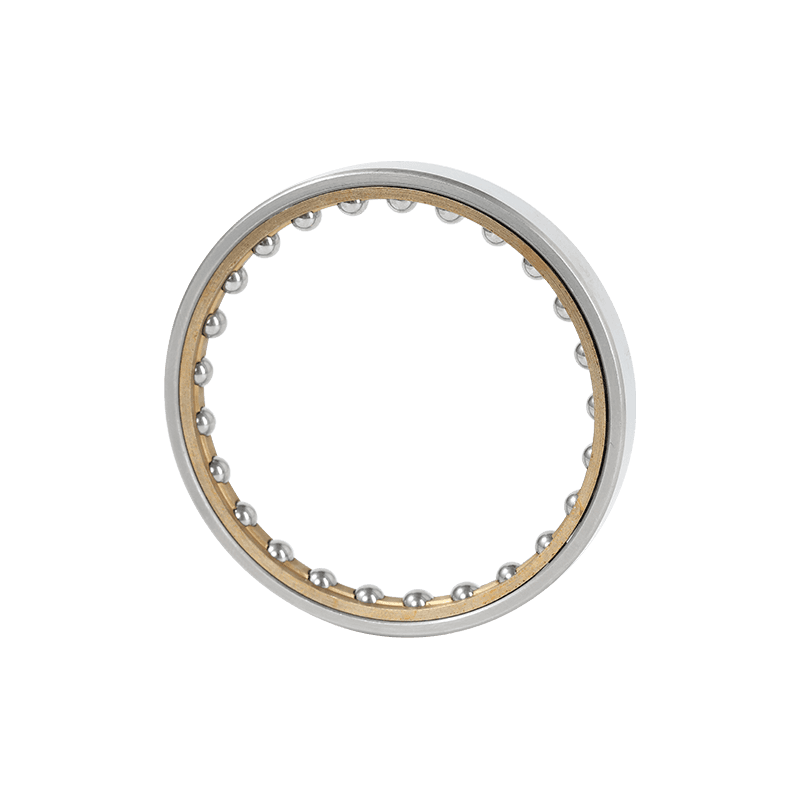

8. Question: What impact does the cage have on the performance of angular contact bearings? What are the common types of cages?

* A: Although the cage is not the main load-bearing component, its function is crucial:

* Separating the rolling elements: Preventing them from colliding and rubbing against each other, especially at high speeds. * Guiding rolling element movement: Maintaining uniform spacing and optimizing load distribution.

* Lubricant channels: Designed to influence the flow and distribution of lubricating oil.

Common cage types:

* Stamped steel cage: Low cost, high strength, widely used.

* Machined brass cage: High strength, good wear resistance, excellent thermal conductivity, suitable for high-speed, heavy-load, or impact conditions; a common choice for high-performance bearings.

* Engineering plastic cage (e.g., PEEK, PA66): Lightweight, low coefficient of friction, self-lubricating, suitable for high-speed applications requiring low noise and low friction, but sensitive to high temperatures and certain chemical media.

Ningbo Jinxin Bearing Technology Co., Ltd. selects the most suitable cage material and structure according to different bearing series and application requirements to optimize the overall performance of the bearing.

9. Question: How critical is the lubrication of angular contact bearings to their lifespan and performance? What should be considered when selecting a lubricant?

* A: Lubrication is the "lifeline" of bearings, and its core functions are:

* Reducing friction and wear: Forming an oil film between the rolling elements and raceways.

* Heat dissipation: Removing heat generated during bearing operation.

* Rust and corrosion prevention: Protecting metal surfaces.

* Sealing: Helping to block contaminants.

When selecting a lubricant (grease or oil), the following must be considered:

* Operating temperature range: The lubricant must maintain effective performance at both the lowest and highest operating temperatures.

* Speed (DN value): Low-viscosity, low-friction, and anti-volatile lubricants are required for high speeds.

* Load type and magnitude: High-viscosity lubricants or those containing extreme pressure additives are required for heavy loads.

* Environmental factors: Such as exposure to moisture, dust, and chemicals.

* Seal type: Compatibility with sealing materials.

Ningbo Jinxin Bearing Technology Co., Ltd. provides standard lubrication with its products upon delivery. Furthermore, its technical team can offer professional lubrication selection advice tailored to specific customer operating conditions (such as extreme temperatures, high speeds, heavy loads, vacuum, and clean environments). This reflects its commitment to providing comprehensive solutions based on integrity.

10. Q: How to assess the operating condition and potential faults of angular contact bearings?

* A: Effective condition monitoring is crucial for preventing faults and ensuring reliable equipment operation. Key monitoring methods include:

* Vibration analysis: Detecting abnormal vibration spectra caused by bearing damage (pitting, spalling) or installation problems.

* Temperature monitoring: Abnormal temperature rises often indicate lubrication failure, excessive preload, or severe wear.

* Noise monitoring: Abnormal noise is one of the early signs of bearing damage.

* Lubricant condition analysis: Detecting the degree of oil deterioration and the composition and morphology of abrasive particles.

* Regular disassembly and inspection: Inspecting bearing wear, fatigue marks, cage condition, etc., during planned maintenance.

Ningbo Jinxin Bearing Technology Co., Ltd. understands the value of reliability. Its rigorous quality control during product design and manufacturing provides a solid foundation for end-users to achieve effective condition monitoring and long-life operation.

The design and application of angular contact bearings is a systems engineering project integrating materials science, mechanics, tribology, and precision manufacturing. Every technical detail directly affects the performance of the final equipment. Ningbo Jinxin Bearing Technology Co., Ltd., adhering to the core philosophy of "quality as the foundation, integrity as the cornerstone," focuses on the research and development and manufacturing of precision bearings such as angular contact bearings. Its professional engineering team is dedicated to deeply understanding the principles of bearing technology and translating this understanding into product reliability and performance advantages.

Whether facing the challenges of bearing selection under complex operating conditions or seeking optimization solutions for existing equipment performance, Ningbo Jinxin Bearing Technology Co., Ltd. looks forward to in-depth technical exchanges and cooperation with industry peers. We believe that through professional knowledge sharing and reliable bearing products, we can jointly promote the efficiency improvement and reliable operation of industrial equipment.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch