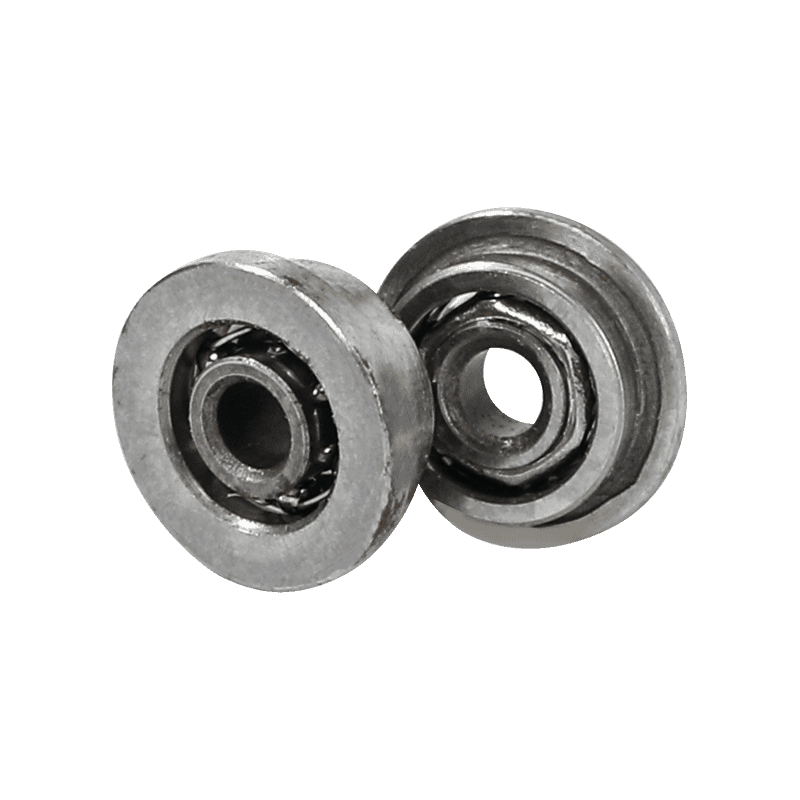

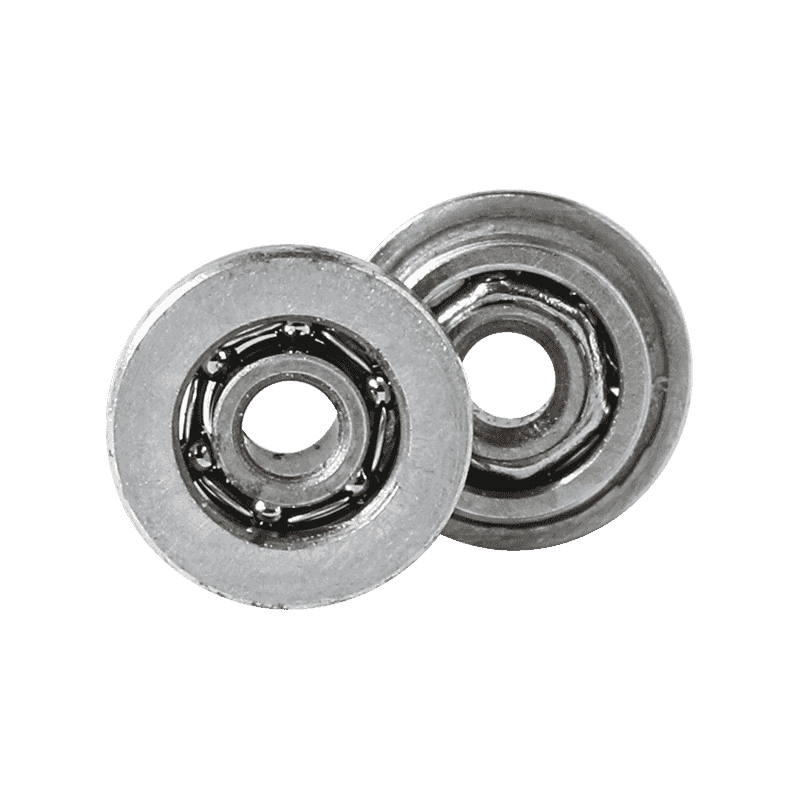

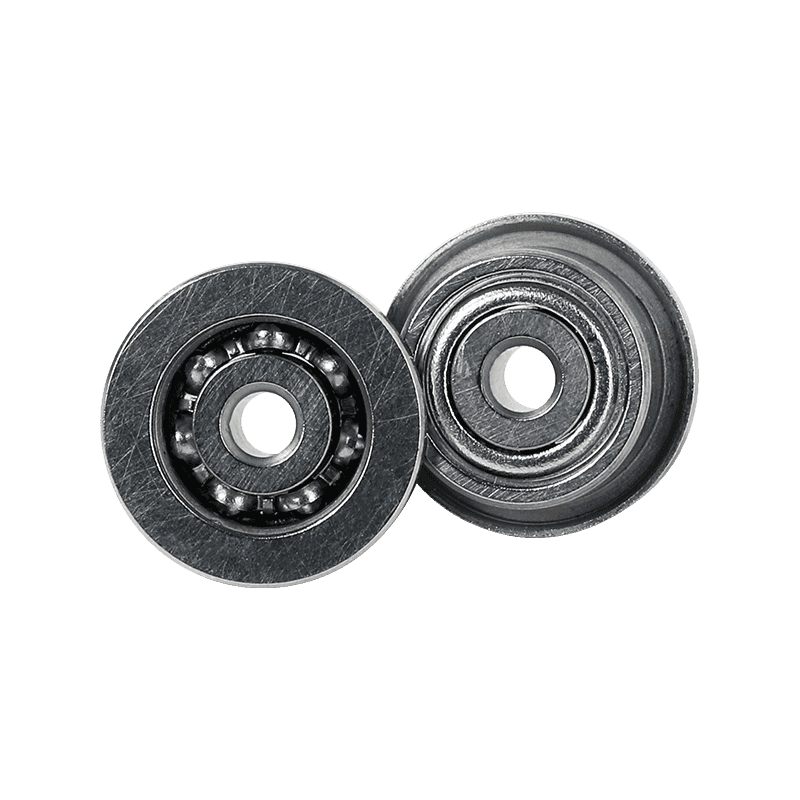

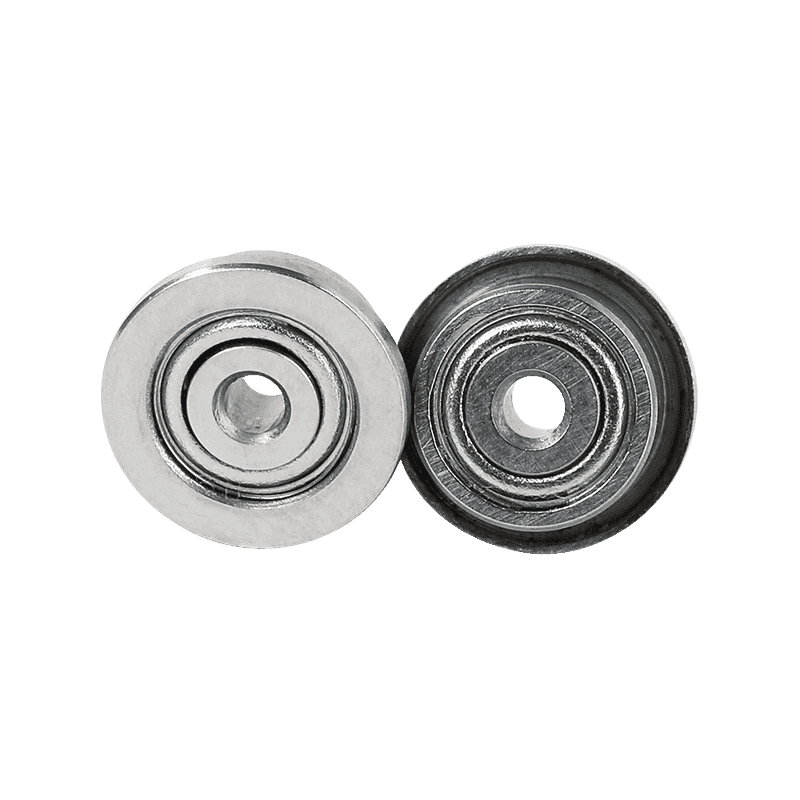

In the industrial manufacturing sector, customized non-standard bearings play a crucial role, overcoming the limitations of standardized products and meeting the unique needs of specific application scenarios. As a representative of this field, Ningbo Jinxin Bearing Technology Co., Ltd. demonstrates how manufacturers can solve complex problems through innovative processes and rigorous management.

1. What is the core business of a customized non-standard bearing manufacturer?

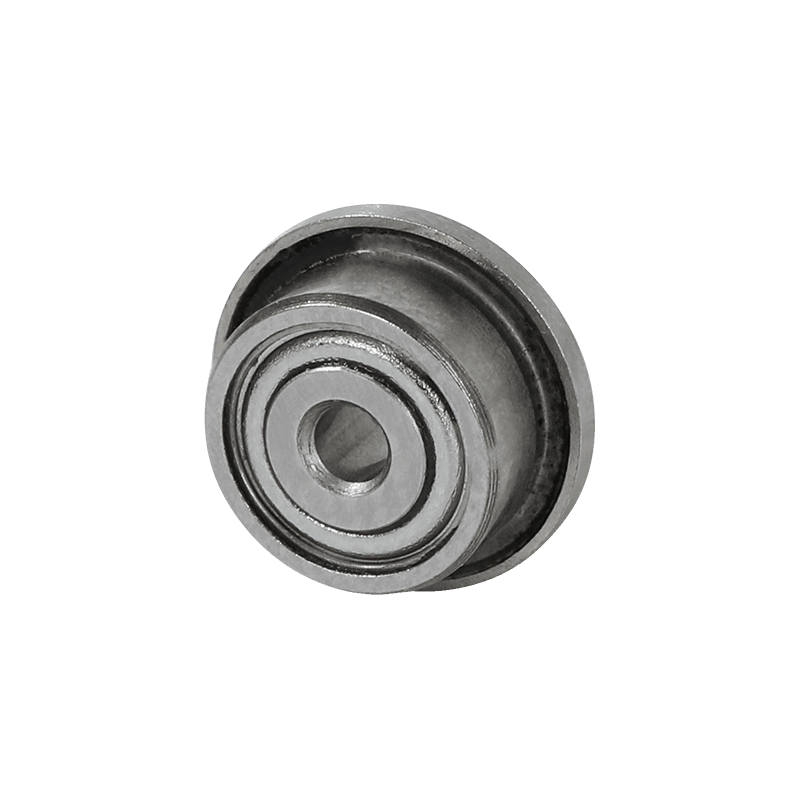

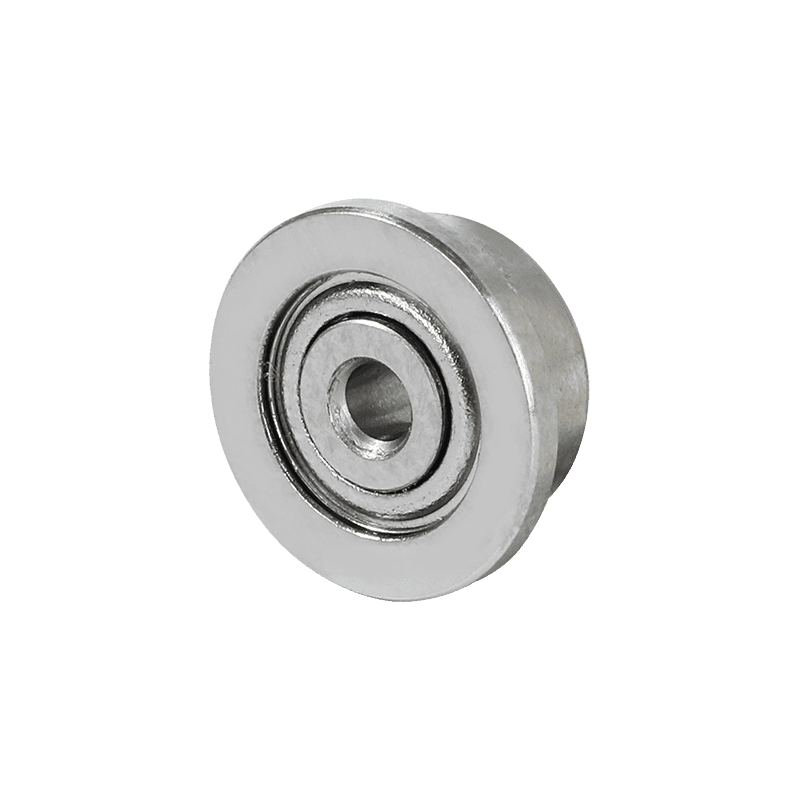

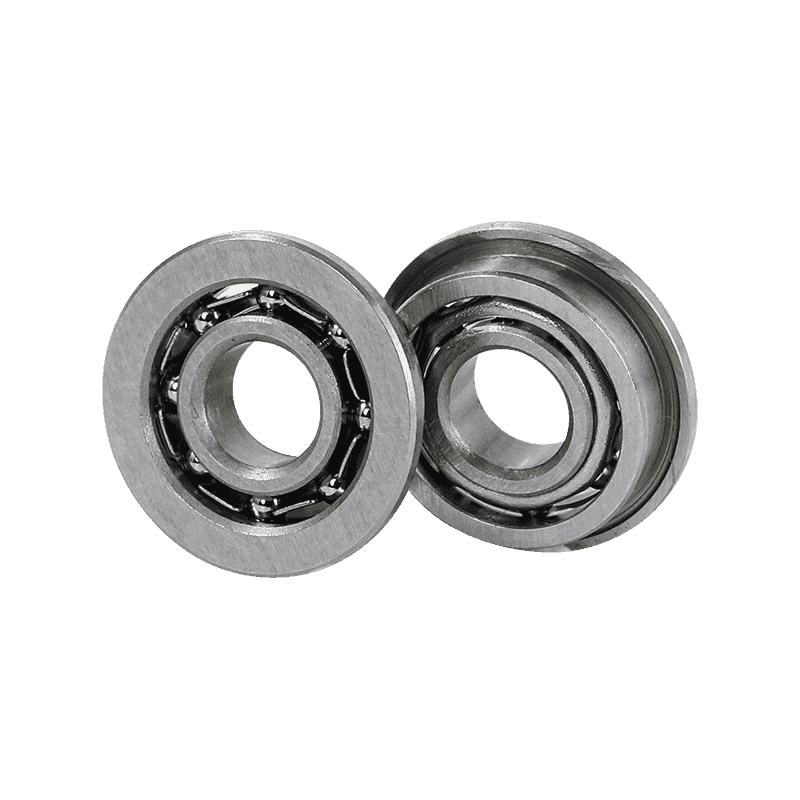

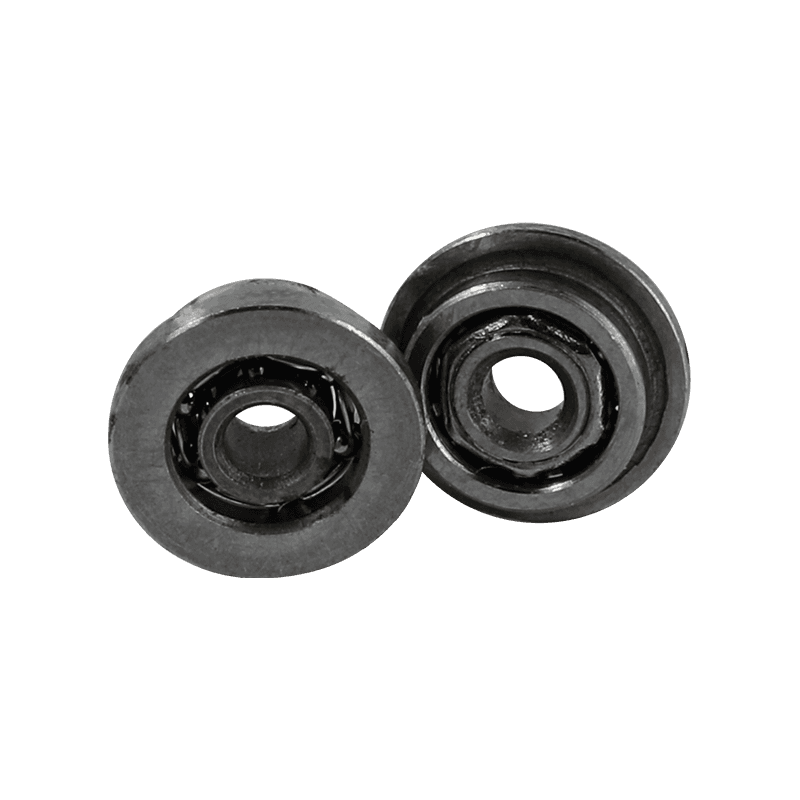

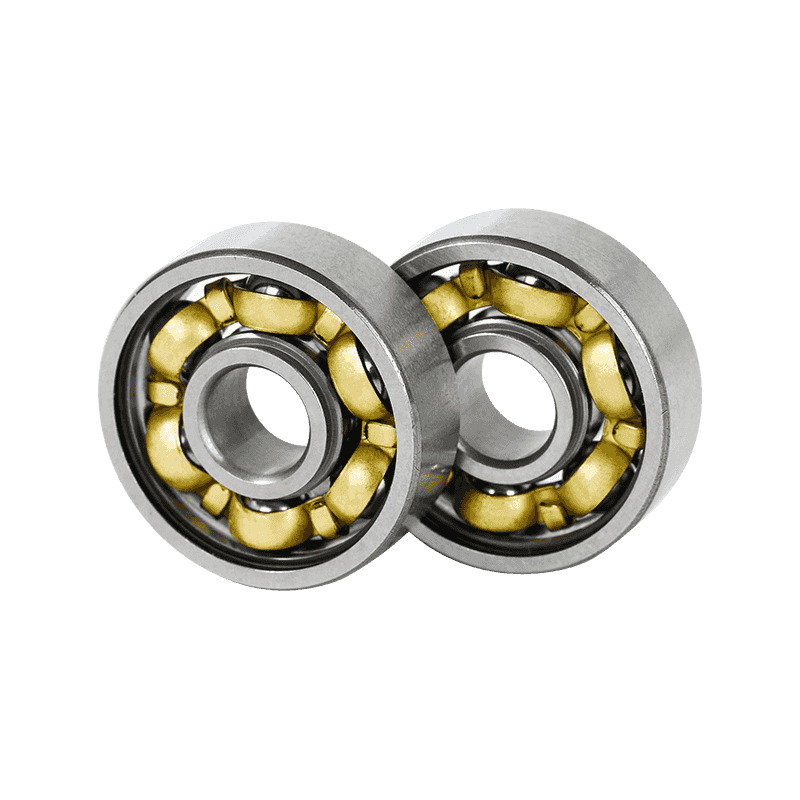

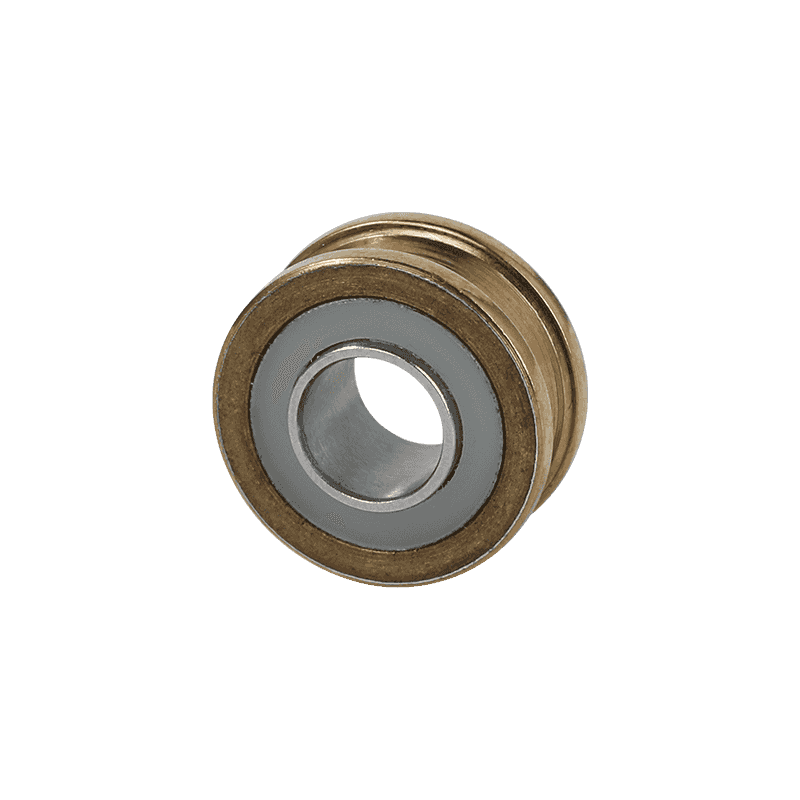

The core business of a customized non-standard bearing manufacturer lies in designing and producing non-standard bearing products that are customized to meet the specific application needs of customers, such as special dimensions, materials, or performance characteristics. Unlike mass-producing standard bearings, manufacturers must integrate engineering knowledge, design flexibility, and production adaptability to ensure that products can cope with extreme operating conditions or unique mechanical system requirements. For example, Ningbo Jinxin Bearing Technology Co., Ltd. focuses on handling diverse specifications and precision grades within its business framework, demonstrating how manufacturers can transform customer needs into practical solutions through a systematic approach. This business model emphasizes end-to-end customization capabilities from conceptual design to final delivery.

2. Why does the industrial sector need to shift towards customized non-standard bearing solutions?

The industrial sector is shifting towards customized, non-standard bearing solutions due to the inability of standard products to meet performance, lifespan, or compatibility requirements in complex equipment or specific environments. Customized bearings can optimize load distribution, reduce frictional losses, or adapt to specific temperature ranges, thereby improving overall mechanical efficiency. Manufacturers like Ningbo Jinxin Bearing Technology Co., Ltd. leverage their processing capabilities to handle special requirements, ensuring product reliability in demanding applications. This highlights the necessity of customization in addressing technological innovation and market diversification, avoiding downtime risks caused by compatibility failures.

3. What are the main technical challenges in manufacturing customized, non-standard bearings?

The core challenges in the manufacturing process include design verification, material selection, and process optimization. The design phase requires simulating actual operating conditions to predict bearing behavior, while material selection must consider characteristics such as corrosion resistance and fatigue strength. The process phase requires balancing production efficiency with precision control to prevent product failure due to minor deviations. Ningbo Jinxin Bearing Technology Co., Ltd. implements rigorous quality control processes in its production system, turning these challenges into advantages and ensuring that every step meets high-precision requirements. This demonstrates how manufacturers can overcome technical bottlenecks through a systematic approach.

4. How is Quality Control a Key Pillar in Custom Non-Standard Bearing Manufacturing?

Quality control is the cornerstone of custom non-standard bearing manufacturing. It permeates the entire process, from raw material inspection to finished product testing, ensuring product consistency, durability, and safety. Manufacturers must establish closed-loop monitoring systems, including dimensional accuracy verification, surface treatment evaluation, and performance simulation testing, to prevent defects from entering the market. Taking Ningbo Jinxin Bearing Technology Co., Ltd. as an example, its implementation of rigorous quality control processes throughout the entire production chain reinforces its commitment to consistent product quality. This demonstrates how quality control can serve as a risk mitigation tool, ensuring zero-failure operation of custom bearings in critical applications.

5. What Role Does Material Innovation Play in Custom Non-Standard Bearings?

Material innovation is a core element driving the performance of custom bearings. It involves developing new alloys, composite materials, or coating technologies to meet specific load, speed, or environmental requirements. Manufacturers must select materials based on the application scenario, such as heat-resistant steel for high-temperature conditions or stainless steel for corrosive environments, which directly affects bearing life and efficiency. Ningbo Jinxin Bearing Technology Co., Ltd. demonstrates its expertise in handling special requirements through material optimization, reflecting an industry trend: manufacturers must continuously develop material solutions to support customers' goals in energy conservation, sustainability, and other areas.

6. In which industrial applications do customized non-standard bearings offer the greatest value?

Customized non-standard bearings are particularly valuable in high-end industrial applications such as aerospace, medical devices, or renewable energy equipment, where precision matching, low noise, or high reliability are required. Custom solutions provide tailored solutions when standard bearings fall short, such as micro-bearings for microrobot joints or heavy-duty bearings for wind turbines. Ningbo Jinxin Bearing Technology Co., Ltd.'s processing capabilities cover a wide range of applications, highlighting how manufacturers can drive industry innovation and efficiency improvements through customized services.

7. How to assess the overall strength of a customized non-standard bearing manufacturer?

Assessing a manufacturer's strength requires considering its engineering support, production flexibility, and quality management system. Key indicators include design response speed, process maturity, and quality control coverage, rather than relying on a single product parameter. Manufacturers like Ningbo Jinxin Bearing Technology Co., Ltd. have demonstrated their comprehensive strength by meeting diverse specifications. This underscores the importance of prioritizing a partner's ability to systematically solve complex problems, rather than short-term cost factors, when selecting a partner.

8. How will the customized non-standard bearing manufacturing industry evolve to adapt to emerging demands in the future?

Future evolution will be driven by intelligent manufacturing and sustainability, including the introduction of AI-aided design, additive manufacturing technologies, and green materials to accommodate trends towards personalization and small-batch production. Manufacturers need to strengthen collaborative models and jointly develop innovative solutions with customers. Ningbo Jinxin Bearing Technology Co., Ltd.'s quality control orientation foreshadows the industry's transformation towards greater flexibility and reliability, reflecting the manufacturer's strategic positioning in a rapidly changing market.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch