Deep groove ball bearings, as a fundamental and crucial mechanical component, play an indispensable role in modern industry.

Question: What is the basic definition of a deep groove ball bearing?

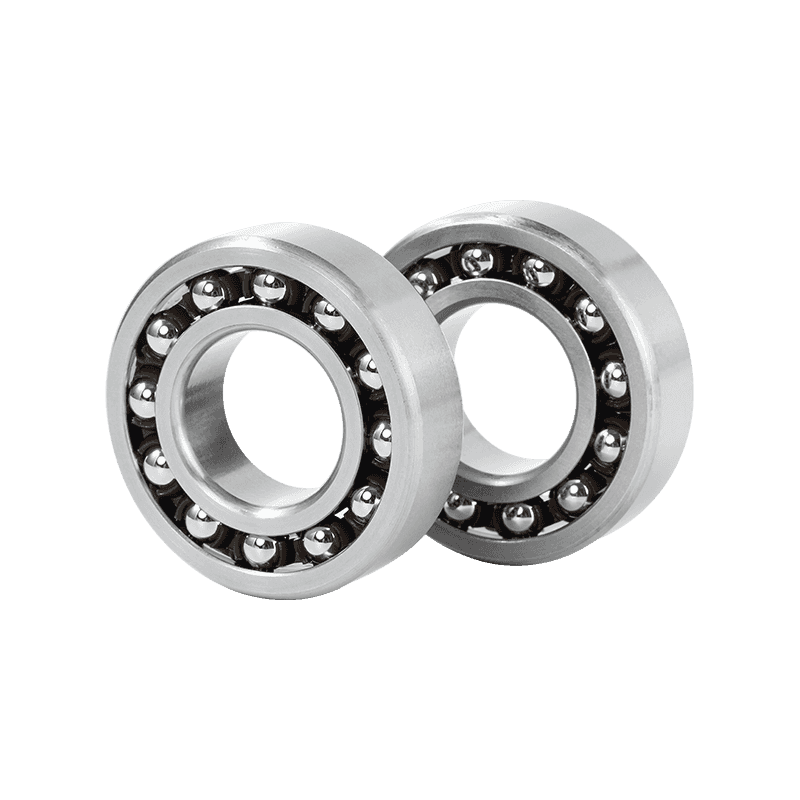

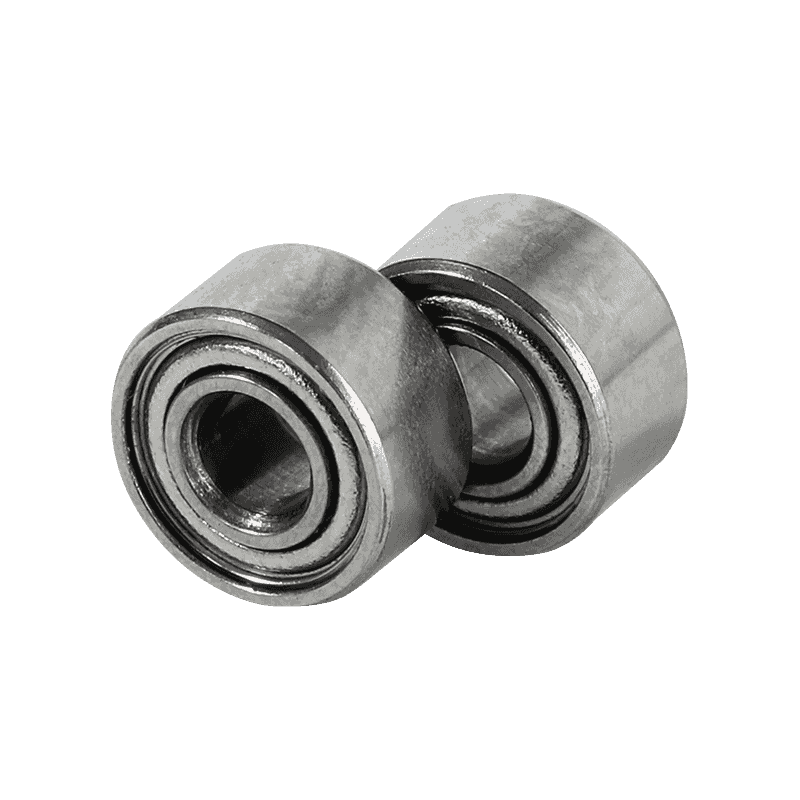

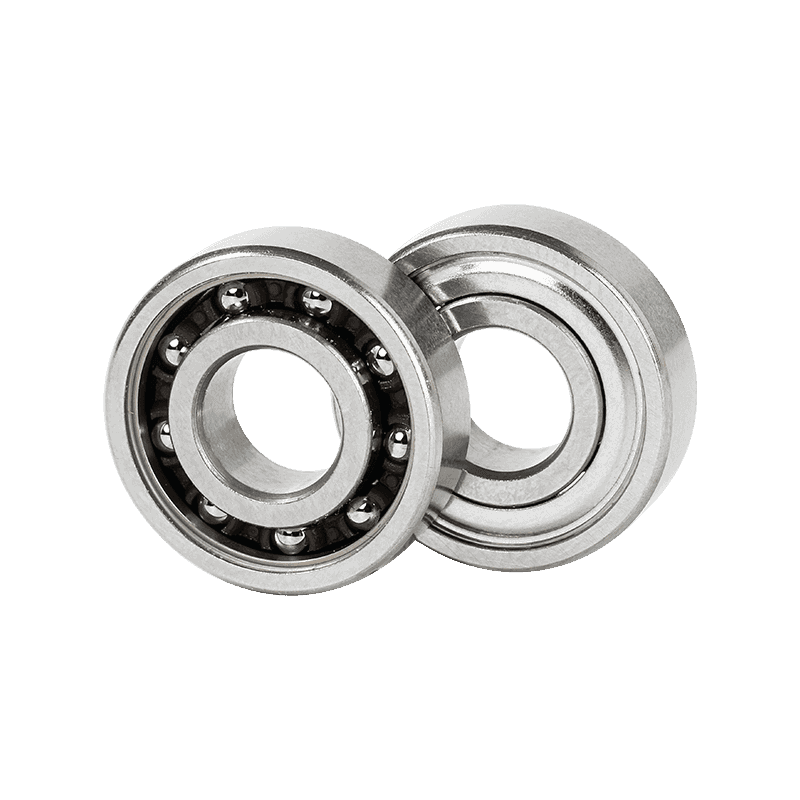

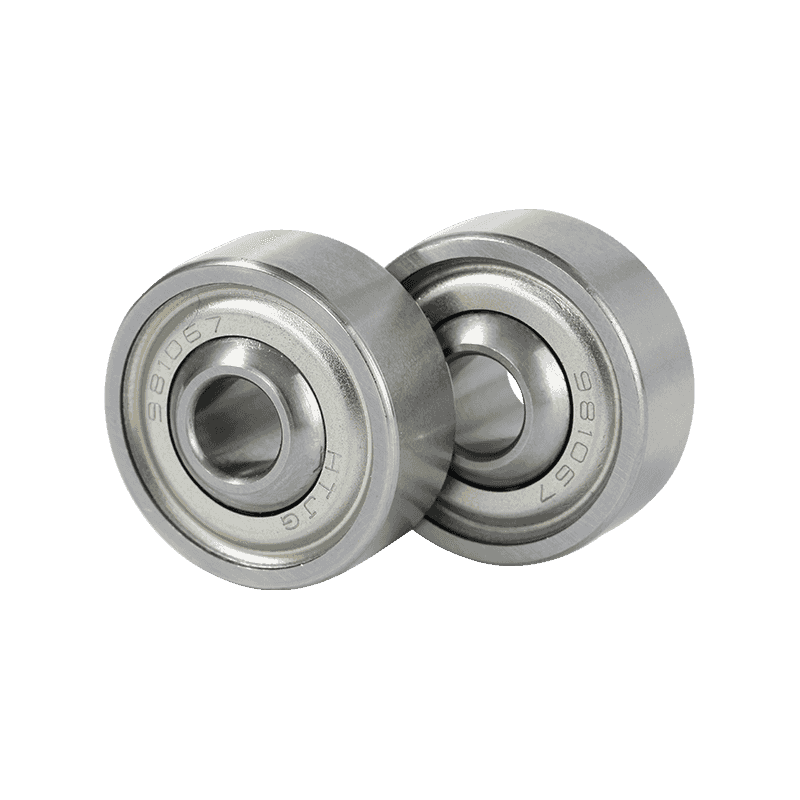

A deep groove ball bearing is a common type of rolling bearing. Its structure is centered on a deep groove design, containing balls and a cage internally, and consisting of inner and outer rings externally. This design allows the bearing to withstand both radial and axial loads simultaneously, making it suitable for high-speed rotating environments. The simple construction of deep groove ball bearings makes them easy to install and maintain, and they are widely used in various types of rotating machinery. Ningbo Jinxin Bearing Technology Co., Ltd., through its complete manufacturing process equipment, such as CNC lathe machining production lines, can precisely produce the inner and outer rings of this type of bearing, ensuring the accuracy of groove depth and shape to meet the needs of different operating conditions.

Question: What are the main characteristics and advantages of deep groove ball bearings?

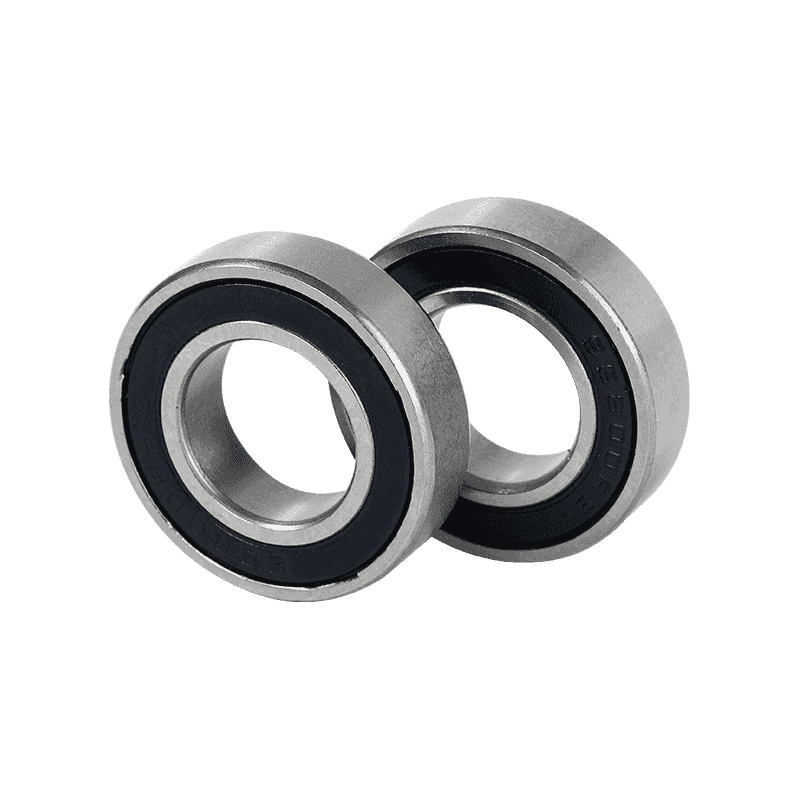

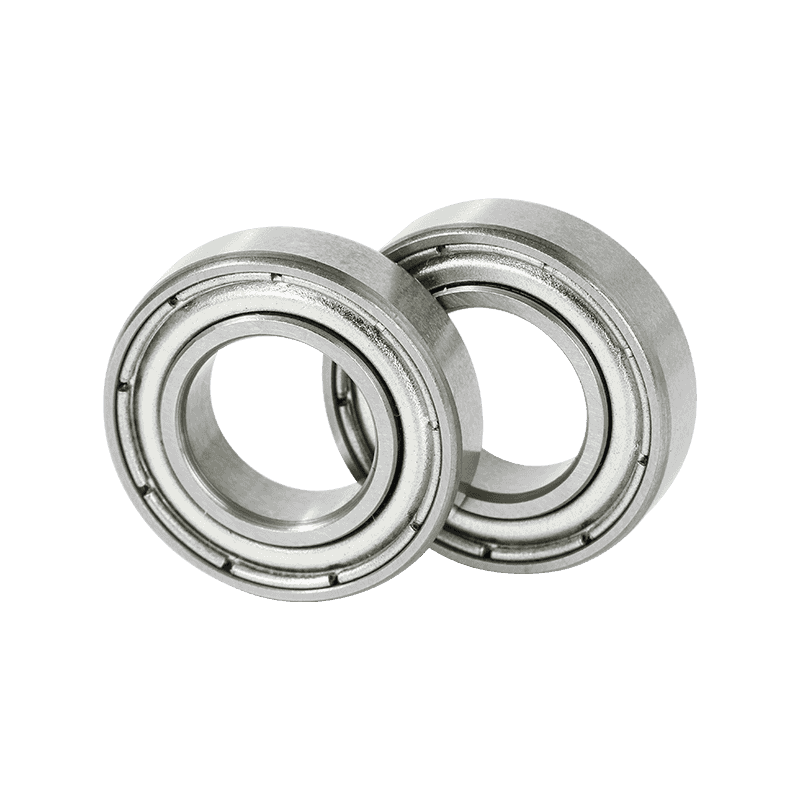

The main characteristics of deep groove ball bearings include high load capacity, low coefficient of friction, and excellent operational stability. Their deep groove design provides excellent load distribution, reducing localized stress concentration and thus extending service life. Furthermore, these bearings offer a variety of sealing options to adapt to humid or contaminated environments. In terms of advantages, deep groove ball bearings are highly versatile, require minimal maintenance, and significantly improve the efficiency and reliability of mechanical systems. Ningbo Jinxin Bearing Technology Co., Ltd. utilizes grinding production lines and heat treatment processes to precisely control the hardness and surface finish of bearings, further enhancing these advantages and ensuring high performance even under harsh conditions.

Question: What are typical industrial applications of deep groove ball bearings?

Deep groove ball bearings are widely used in electric motors, pumps, automotive transmission systems, household appliance motors, and industrial machinery. In these applications, the bearings support rotating components, reduce frictional losses, and ensure smooth operation. Their adaptability makes them perform excellently under high-speed, high-temperature, or variable-load conditions. Ningbo Jinxin Bearing Technology Co., Ltd.'s production capacity covers various specifications and precision grades. Through its cage workshop and heat treatment processes, it customizes bearings suitable for different application environments, such as providing high-speed solutions for the automotive industry or corrosion-resistant designs for industrial pumps.

Question: How does the manufacturing process of deep groove ball bearings affect their performance and quality?

The manufacturing process of deep groove ball bearings involves key steps such as material selection, forming, heat treatment, and precision grinding. High-quality manufacturing ensures the bearing's dimensional accuracy, ball track smoothness, and overall strength, thereby reducing noise, vibration, and the risk of premature failure. The heat treatment process is crucial for improving the bearing's wear resistance and fatigue life, while precision grinding optimizes surface roughness and reduces friction. Ningbo Jinxin Bearing Technology Co., Ltd.'s fully automated CNC equipment, including grinding production lines and heat treatment facilities, ensures consistent geometric accuracy and material properties for each bearing, enabling stable output even under heavy loads or high-speed operation.

Question: How does the design of deep groove ball bearings address the challenges of different operating conditions?

The design of deep groove ball bearings effectively addresses challenges such as high-speed rotation, impact loads, and axial thrust by optimizing groove curvature and ball arrangement. For example, the deep groove structure allows the balls to roll freely, distributing stress and preventing localized overheating. Sealing and lubrication options are designed to withstand dust, moisture, or high-temperature environments, enhancing the bearing's protection capabilities. Ningbo Jinxin Bearing Technology Co., Ltd. utilizes advanced production lines to adjust manufacturing parameters according to different working conditions. For example, CNC lathe machining ensures consistent groove depth, thereby producing specialized bearings suitable for extreme temperatures or high-pollution conditions, enhancing their adaptability and durability.

Question: What factors should be considered when selecting deep groove ball bearings?

Selecting deep groove ball bearings requires evaluating factors such as load type, speed range, environmental conditions, and precision requirements. Applications dominated by radial loads prioritize standard designs, while composite load scenarios require optimization of axial load capacity. Furthermore, lubricant selection and sealing methods directly affect bearing life and efficiency. Ningbo Jinxin Bearing Technology Co., Ltd.'s comprehensive manufacturing capabilities, including heat treatment and cage production, support customized solutions, such as providing ultra-precision ground bearings for high-precision machinery, ensuring low noise and long life, meeting diverse customer needs for reliability and performance.

Question: What are the future development trends of deep groove ball bearings?

The development trends of deep groove ball bearings focus on material innovation, lightweight design, and intelligent integration. New alloy and coating technologies improve wear resistance and energy efficiency, while lightweight structures reduce the overall mechanical load. Intelligent elements, such as embedded sensors, monitor bearing conditions to enable predictive maintenance. Ningbo Jinxin Bearing Technology Co., Ltd. continuously invests in upgrading its manufacturing equipment, driving these trends through CNC production lines and heat treatment processes to produce more environmentally friendly and efficient products, supporting industrial automation and sustainable development.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch