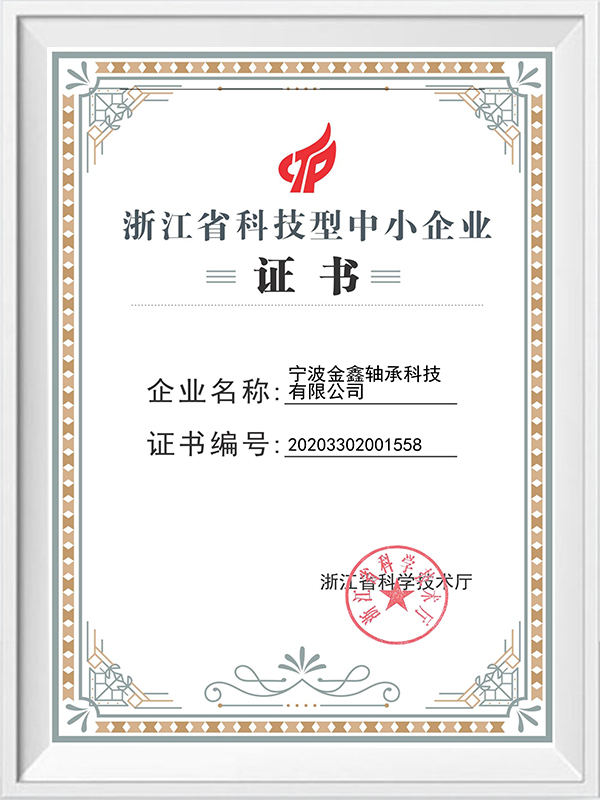

In the field of bearing technology, four-point contact ball bearings have become the preferred choice for many demanding applications due to their unique design and performance advantages. Ningbo Jinxin Bearing Technology Co., Ltd., an IATF 16949 certified company, demonstrates its outstanding capabilities in meeting various special bearing requirements through its advanced CNC lathe machining production lines, grinding production lines, heat treatment workshops, and cage workshops.

1. Q: What is a four-point contact ball bearing? What are the essential differences between it and traditional bearing designs?

A: A four-point contact ball bearing is a special type of rolling bearing. Its core design lies in utilizing four contact points between the balls and the inner and outer rings to achieve load distribution. Compared to traditional single-row or double-row ball bearings, this structure allows the bearing to maintain higher rigidity and stability when subjected to radial and axial loads. The key lies in the bearing's raceway geometry, which optimizes the ball contact angles, ensuring reduced stress concentration during dynamic operation. Ningbo Jinxin Bearing Technology Co., Ltd., relying on its heat treatment workshop and grinding production line, can precisely control the raceway precision level when producing these types of bearings, thereby ensuring the adaptability of the bearings in various applications and avoiding performance losses caused by design deviations. The difference lies in the fact that four-point contact bearings provide greater load-bearing capacity within a limited space without the need for additional support structures, making them particularly efficient in compact equipment.

2. Q: What is the working principle of a four-point contact ball bearing? How does it maintain performance under high load conditions?

A: The working principle of this type of bearing relies on the dynamic distribution of contact points: when a load is applied, the ball forms four-point contact with the inner and outer rings, thereby dispersing stress and reducing local deformation. Under high load or impact conditions, this design strengthens the rigidity of the bearing and prevents raceway slippage or fretting wear. The core mechanism lies in the optimization of the contact angle, which allows the bearing to handle combined loads (such as radial, axial, and moment loads) simultaneously, whereas traditional bearings often require multiple components. Ningbo Jinxin Bearing Technology Co., Ltd., through its CNC lathe machining production line, can achieve precise raceway forming, ensuring that the contact points remain consistent during the manufacturing process and avoiding performance fluctuations. In terms of high load maintenance, the cage design of the bearing is also crucial. It guides the movement of the balls and reduces frictional heat, which is enhanced by the heat treatment process—Ningbo Jinxin's heat treatment workshop can stabilize the microstructure of materials and improve the overall durability of the bearing.

3. Q: What are the main advantages of four-point contact ball bearings? In what aspects are they superior to other types of bearings?

A: The biggest advantage of four-point contact ball bearings lies in their versatility and reliability. First, they significantly simplify equipment design because a single bearing can replace multiple components, saving space and weight. Second, under high precision requirements, the bearing provides excellent rotational accuracy and low noise characteristics, thanks to its evenly distributed contact points, reducing vibration transmission. Compared to deep groove ball bearings or angular contact bearings, it excels in axial load capacity while maintaining comparable radial load performance. Ningbo Jinxin Bearing Technology Co., Ltd. uses grinding production lines in its manufacturing process to ensure surface finish and geometric accuracy, enabling the bearings to easily meet stringent precision requirements, such as in industrial equipment requiring low-tolerance operation. The advantages also extend to service life: optimized contact point distribution reduces the risk of fatigue failure. Ningbo Jinxin, through its cage workshop's customization capabilities, can produce durable cages, further enhancing the bearing's reliability in harsh environments.

4. Q: What are some typical industrial applications of four-point contact ball bearings? How do these applications demonstrate their unique value?

A: These bearings are widely used in fields requiring high load-carrying efficiency and compact design, such as wind turbine generators, robot joint systems, aerospace equipment, and high-end medical devices. In these applications, the core value of the bearing lies in its ability to handle multi-directional loads. For example, in wind turbines, it withstands the enormous torque and wind loads generated by the rotor, ensuring stable operation. Robot joints rely on their compact size and high rigidity to achieve precise motion control. Ningbo Jinxin Bearing Technology Co., Ltd.'s production capacity allows it to customize bearings to meet special requirements, such as enhancing material toughness through heat treatment processes to cope with extreme temperatures or corrosive environments. The application value also lies in reducing maintenance needs: the four-point contact design reduces the wear rate, and Ningbo Jinxin's complete production line ensures that the bearings undergo strict quality control before leaving the factory, meeting high-precision standards, thereby extending the overall lifespan of the equipment.

5. Q: What are the key technical challenges in manufacturing high-quality four-point contact ball bearings? How does the company overcome these challenges through its processes?

A: The key challenges in manufacturing this type of bearing lie in ensuring the consistency of contact points, material strength, and surface integrity. Among these, the accuracy of the raceway forming is a core challenge—any deviation can lead to uneven load distribution and premature failure. Secondly, the heat treatment process requires precise control of the hardness gradient to avoid cracking or deformation. Furthermore, the cage manufacturing must optimize the guiding mechanism to prevent ball slippage or jamming. Ningbo Jinxin Bearing Technology Co., Ltd. achieves micron-level tolerance control through its integrated grinding production line and CNC lathe machining system, ensuring perfect geometric symmetry at each contact point. The heat treatment workshop uses advanced processes to stabilize material properties and improve the bearing's fatigue resistance. The cage workshop focuses on customized design to reduce friction loss. Through these processes, Ningbo Jinxin can handle various specifications and precision levels, demonstrating its professional strength in overcoming challenges in complex manufacturing environments without relying on external documents or regulations.

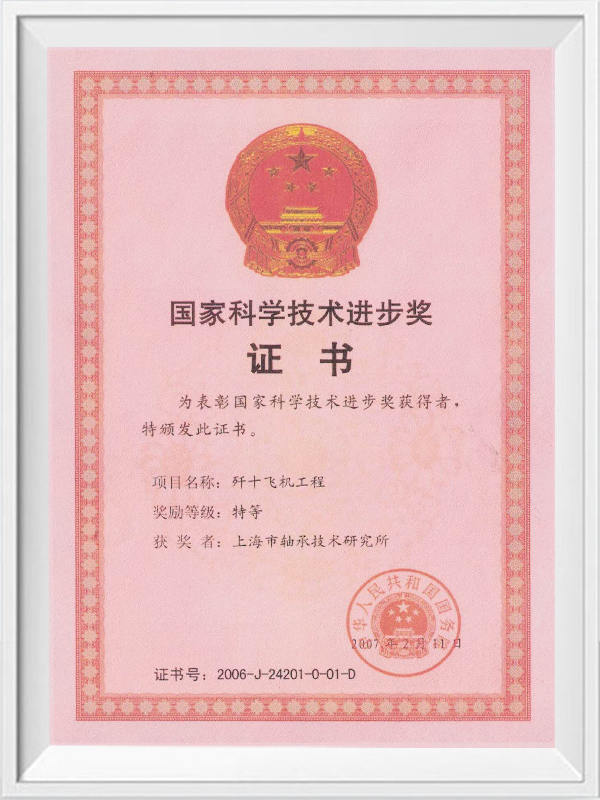

6. Q: How do quality certifications (such as IATF 16949) affect the performance reliability of four-point contact ball bearings? How is it related to company practices?

A: Quality certification systems provide a framework for bearing manufacturing, ensuring that every step from raw materials to finished products meets international standards, thereby improving performance reliability. IATF 16949 emphasizes process control and risk management, which directly affects bearing life and safety: for example, reducing batch-to-batch variation and ensuring the repeatability of contact point design. Ningbo Jinxin Bearing Technology Co., Ltd.'s certification practices are integrated into its daily operations, achieving full-process monitoring through production line integration. From heat treatment to grinding, each step verifies geometric accuracy and material consistency. This relates to core bearing knowledge—certification strengthens preventative maintenance, avoids defect accumulation, and enables bearings to reliably cope with high-load scenarios. Ningbo Jinxin's certification is more than just a label; it's part of its manufacturing philosophy, ensuring customers receive flawless products under specific requirements, reflecting a deep integration of knowledge and industrial practice.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch