In the field of bearing technology, thin section bearings have become key components in high-end industrial applications due to their unique design and performance advantages. The thin-walled structure of these bearings makes them ideal for space-constrained environments, while requiring manufacturers to implement rigorous quality control systems during the design and production processes.

What is the basic definition of thin section bearings? How do they fundamentally differ from traditional bearings?

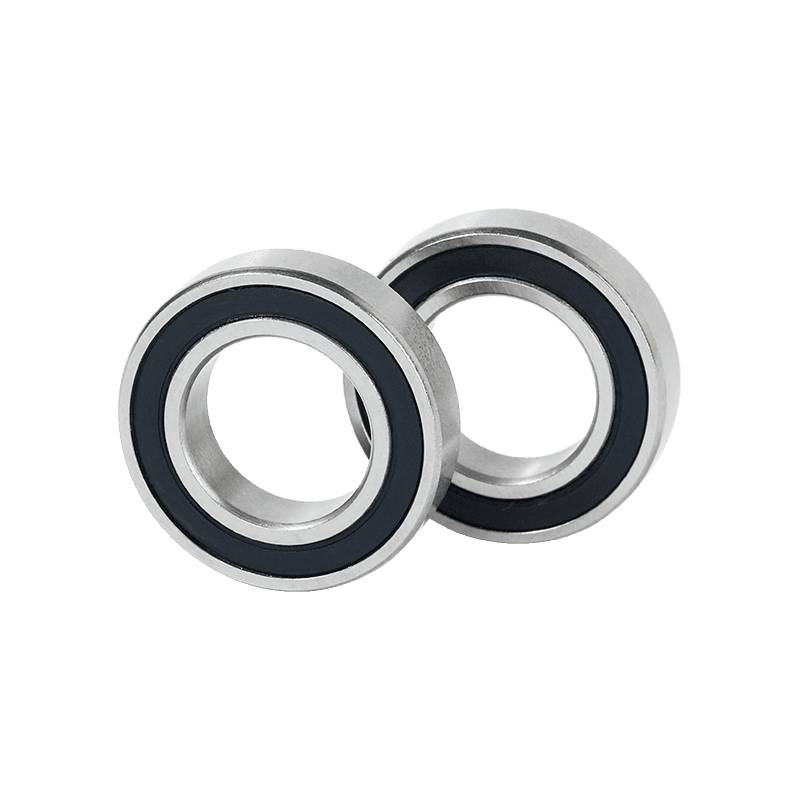

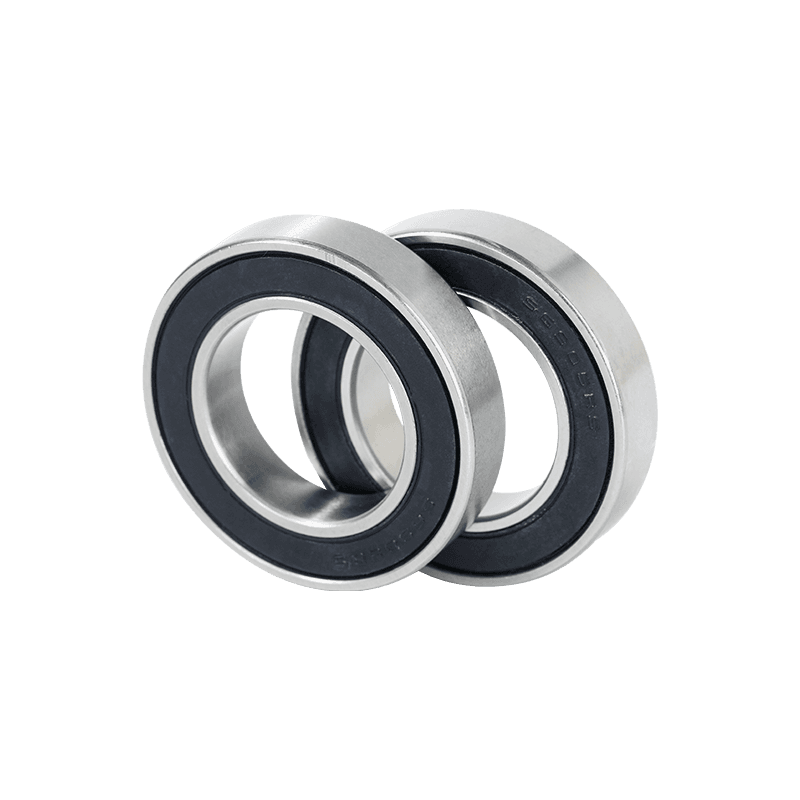

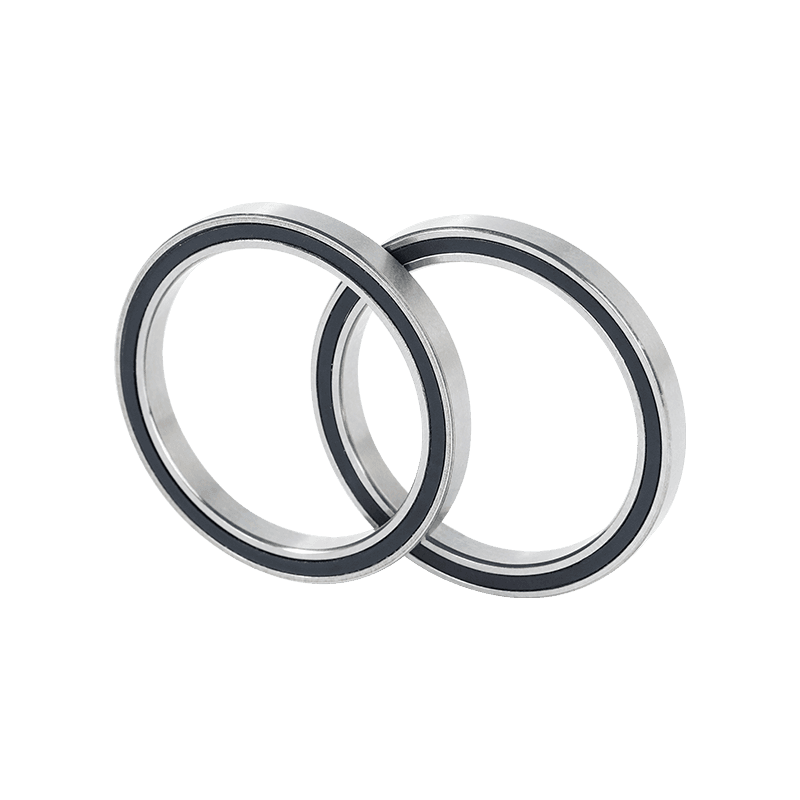

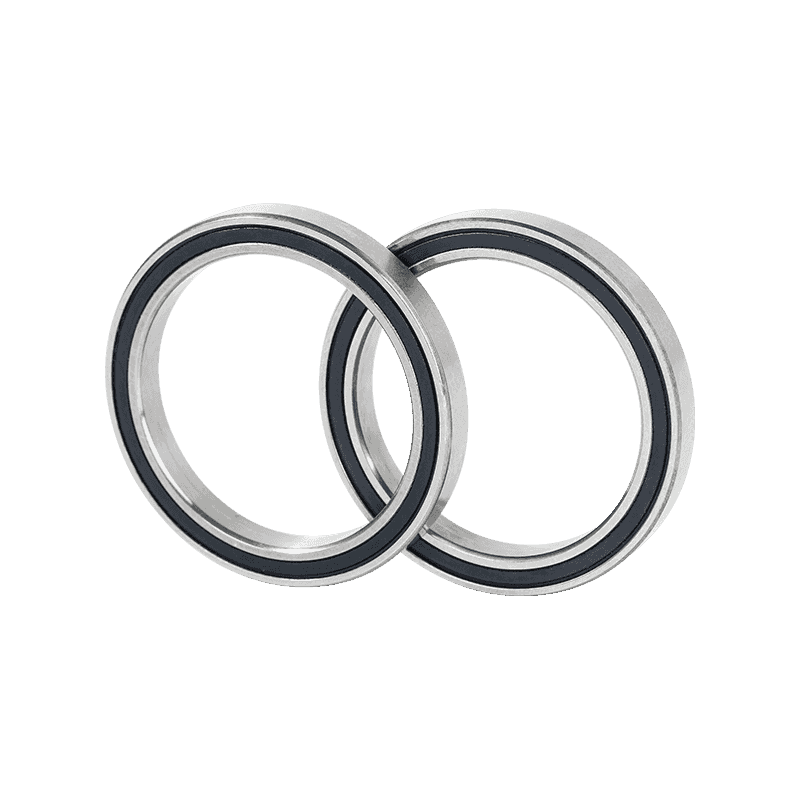

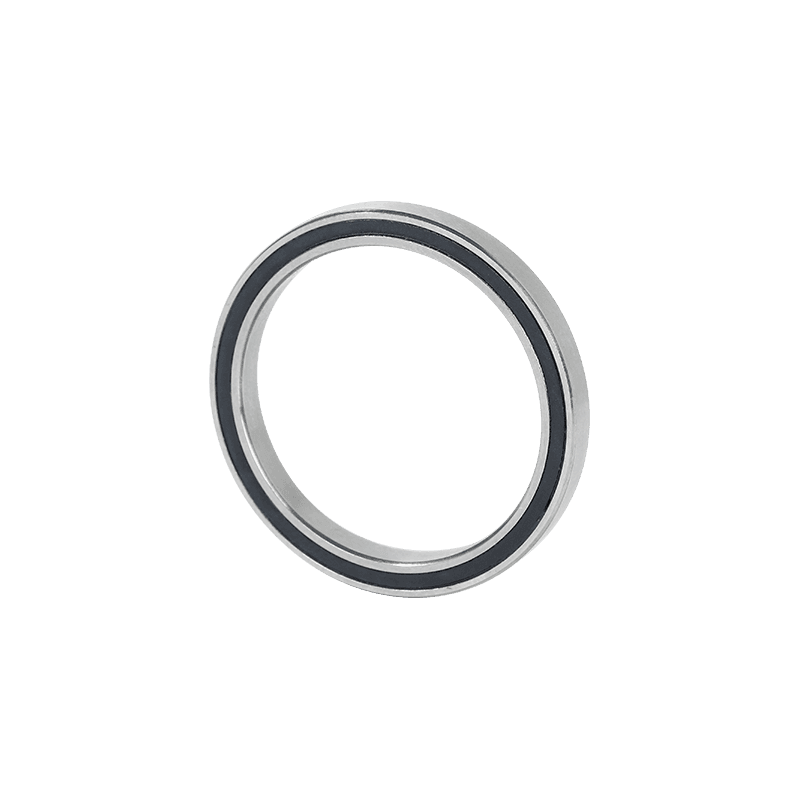

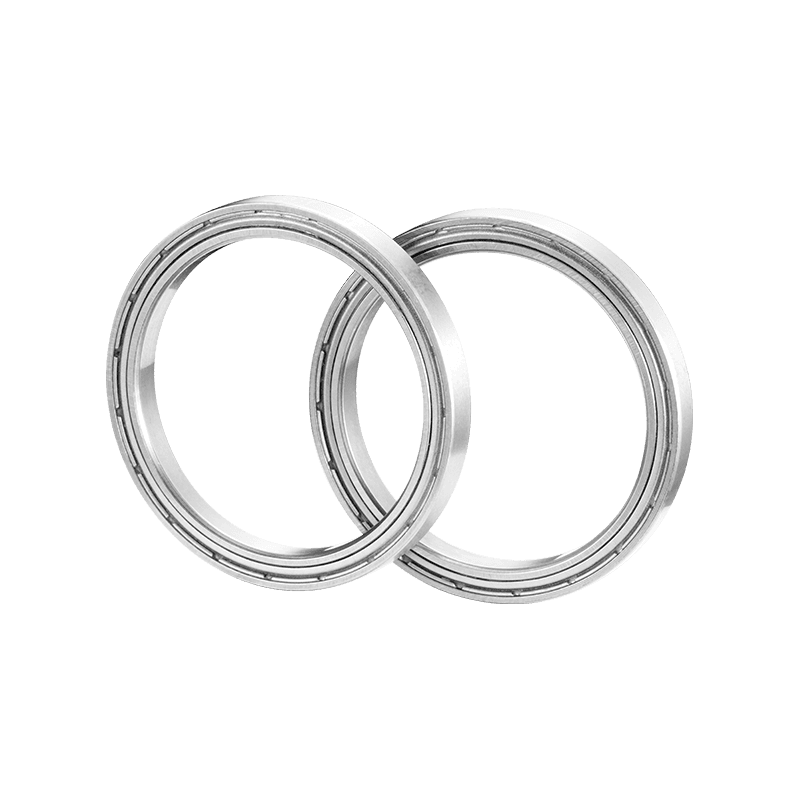

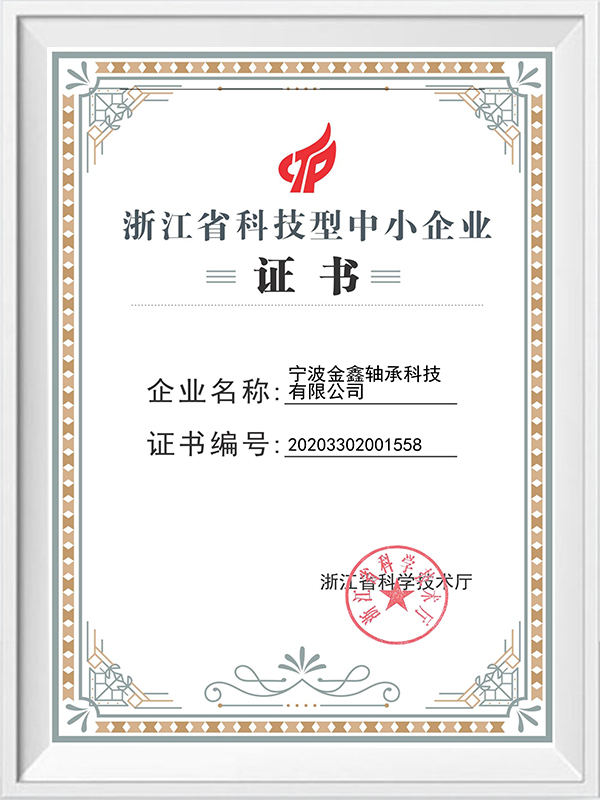

Thin section bearings are compact rolling bearings whose core feature is their thin-walled cross-section structure. This significantly reduces overall size and weight while maintaining high load-bearing capacity. Compared to traditional bearings, they achieve efficient operation within limited space by optimizing the thickness of the inner and outer rings and the rolling element layout. This design not only reduces inertial effects but also improves the dynamic response performance of the system. In the manufacturing process, the pursuit of extreme precision is the differentiating factor, as even the slightest deviation can lead to performance degradation. Ningbo Jinxin Bearing Technology Co., Ltd. demonstrates this emphasis on precision in its pre-shipment dimensional accuracy testing, verifying the geometric tolerances of each bearing with high-precision equipment to ensure seamless integration in practical applications.

Why are thin section bearings so favored in industrial automation? In which key areas do they play a role?

The advantages of these bearings lie in their lightweight and high rigidity, making them ideal for applications requiring high speed, low friction, and precise positioning. For example, in industrial automation systems, thin section bearings effectively reduce the inertial load on robotic arms, thereby improving motion accuracy and efficiency. They are also widely used in medical devices, aerospace, and robotics, where components often need to withstand complex loads within confined spaces. However, the thin-walled design also presents challenges, such as higher requirements for material uniformity and surface finish. Quality control measures, such as hardness testing implemented by Ningbo Jinxin Bearing Technology Co., Ltd., ensure that bearing materials maintain stable strength and wear resistance throughout their lifespan, preventing premature failure due to stress concentration.

What are the main technical challenges engineers face when designing and manufacturing thin section bearings? How can these obstacles be overcome?

Key challenges include uneven stress distribution under thin-walled structures, the risk of thermal deformation, and maintaining accuracy during installation. Engineers must optimize bearing geometry, for example, by simulating load paths through finite element analysis, to minimize the negative impact of wall thickness on rigidity. Material selection is also crucial, requiring a balance between lightweight and high strength. Common solutions include using special alloys or surface treatments to enhance durability. Precise control of heat treatment and grinding processes is critical during manufacturing; any deviation can affect the bearing's fatigue life. Ningbo Jinxin Bearing Technology Co., Ltd.'s fatigue life testing process addresses these challenges by simulating long-term operating conditions to verify bearing reliability, ensuring consistent performance even in extreme environments.

What role does materials science play in thin-section bearings? How do different materials affect the overall performance of bearings?

Material selection directly determines the bearing's load-bearing capacity, corrosion resistance, and service life. Engineers typically choose high-purity steel or ceramic composites to optimize the balance between hardness and toughness. For example, high-carbon steel provides excellent compressive strength, while adding alloying elements improves fatigue resistance. The heat treatment process also requires meticulous control to avoid microcracks caused by internal stress. This necessitates manufacturers implementing comprehensive hardness testing to ensure uniformity from the core to the surface of the material. Ningbo Jinxin Bearing Technology Co., Ltd. uses advanced equipment in its testing to accurately assess material hardness distribution, ensuring that bearings do not undergo plastic deformation or premature wear in high-load applications.

Why is quality control a core aspect of thin section bearing manufacturing? How does it guarantee the performance consistency of the final product?

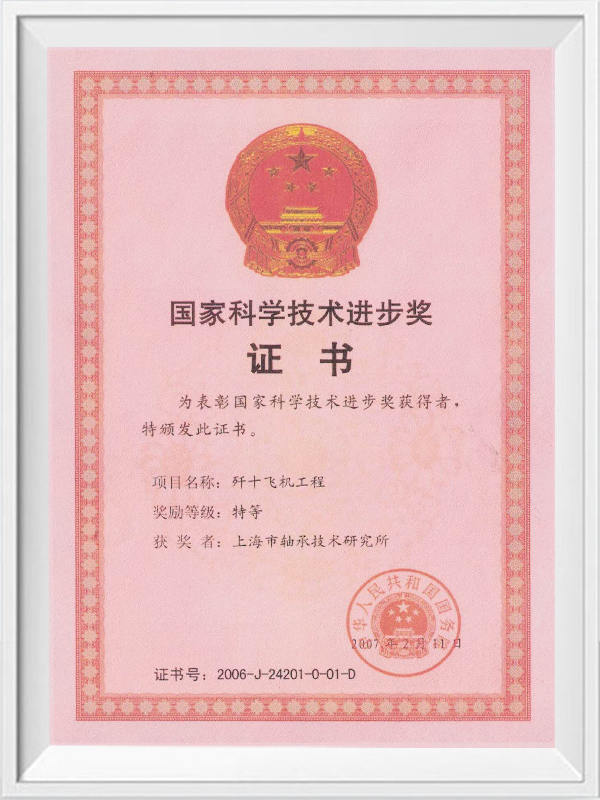

Quality control is fundamental to ensuring reliable bearing operation in demanding applications because the sensitivity of thin-walled designs amplifies the impact of any manufacturing defects. Through multi-stage testing protocols, manufacturers can identify and correct dimensional deviations, material defects, or assembly issues. This includes dimensional accuracy testing to verify tolerance compliance, hardness testing to monitor material integrity, and fatigue life testing to predict long-term durability. Ningbo Jinxin Bearing Technology Co., Ltd.'s practices highlight this: they perform these rigorous testing procedures before each batch of products leaves the factory, using industry-leading equipment to generate authoritative data, thereby ensuring stable bearing performance in high-speed, high-precision scenarios. This system not only enhances product reliability but also drives the evolution of industry standards.

How should users optimize system design based on their knowledge of thin section bearings during bearing maintenance and selection?

Users need to consider the load type, speed, and space constraints of the application environment to select a suitable bearing configuration. For example, in robot joints, thin-section bearings capable of withstanding combined radial and axial loads are preferred, while preload design reduces the impact of clearance. In terms of maintenance, regular checks of lubrication and installation accuracy can extend lifespan, as thin-walled bearings are more sensitive to contamination and misalignment. The quality control philosophy of Ningbo Jinxin Bearing Technology Co., Ltd. can be adopted in this regard: their testing processes emphasize preventative verification to help users avoid system downtime due to component failure. Ultimately, knowledge-driven selection maximizes bearing efficiency and reliability.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch