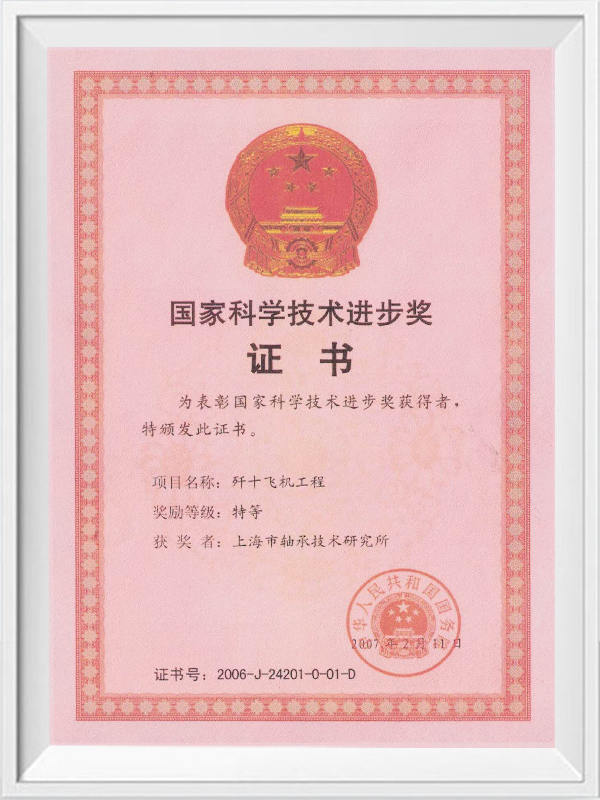

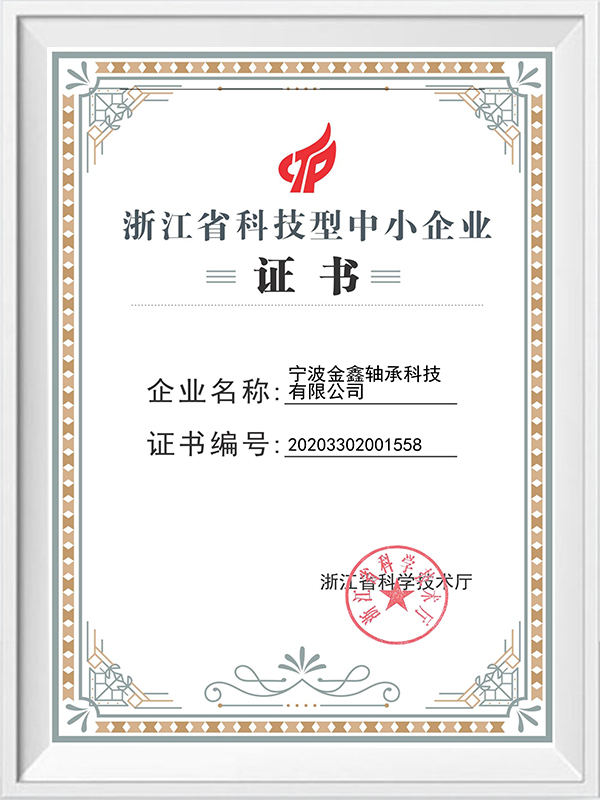

Large bore thin-wall bearings play a crucial role in industrial applications, especially when space is limited but high load capacity and lightweight design are required. As a leading provider of bearing solutions, Ningbo Jinxin Bearing Technology Co., Ltd., with its professional sales team, frequently answers various questions for customers. Team members not only possess in-depth product knowledge but also provide precise advice tailored to specific challenges, helping customers find the optimal solution.

1. What are large bore thin-wall bearings? Why are they so critical in certain industries?

The core design of large bore thin-wall bearings lies in their large bore diameter and ultra-thin wall characteristics, typically used to achieve efficient load transfer within limited space. These bearings reduce overall weight while maintaining high rigidity and precise rotational performance by optimizing the wall thickness to bore ratio. Why are they the preferred choice in industrial automation or precision equipment? Because their design significantly saves installation space and adapts to dynamic requirements under high or low speed operation. For example, in robot joints or medical imaging systems, the thin-wall structure allows for more compact assembly, while the large bore facilitates the integration of drive shafts or other components. The expert team at Ningbo Jinxin Bearing Technology Co., Ltd. frequently emphasizes that when selecting these types of bearings, priority should be given to the spatial constraints and load type of the application environment, rather than blindly pursuing specifications. Their real-time consultation helps customers avoid common pitfalls and ensures a perfect match between the bearing and the system.

2. What are the main characteristics of large-bore thin-walled bearings? How do these characteristics affect actual performance?

The outstanding features of these bearings include lightweight construction, high load density, and excellent elastic deformation control. Lightweight construction stems from the thin-walled design, which significantly reduces the inertia of moving parts and improves system response speed; while high load density ensures the ability to withstand large radial or axial forces in confined spaces. However, how do these characteristics translate into practical advantages? In actual operation, the thin walls may lead to higher tolerance sensitivity, therefore material selection and manufacturing precision are crucial—for example, using high-strength alloys or special heat treatments can enhance wear resistance and prevent performance degradation due to minor deformations. The sales team at Ningbo Jinxin Bearing Technology Co., Ltd. often reminds customers that these bearings must be properly aligned during installation, otherwise eccentric wear may occur. Through their professional guidance, customers can learn how to assess bearing fatigue life and dynamic stability, thus anticipating potential problems before procurement.

3. In which industrial applications are large-bore thin-walled bearings most common? What unique requirements do these applications place on bearings?

Large-bore thin-walled bearings are widely used in robotics, aerospace components, and medical devices. Why are they capable of high-speed rotation in robotic arms? Because the thin-walled structure allows for more flexible joint designs, reducing overall weight and improving precision. In aerospace components, the large bore facilitates the integration of sensors or cables, while lightweight construction contributes to fuel efficiency. However, these applications often bring demanding requirements: for example, medical devices require sterile environments and low-noise operation, demanding bearing materials with corrosion resistance and ultra-smooth surfaces. Aerospace emphasizes stability under extreme temperatures, requiring bearings to withstand thermal expansion and contraction without loss of precision. Experts at Ningbo Jinxin Bearing Technology Co., Ltd. point out that the needs of different industries vary greatly, and their team, through in-depth dialogue, can help customers identify these implicit requirements—such as prioritizing seal design and lubrication compatibility to avoid unexpected failures in applications.

4. What are the key factors to consider when selecting large-bore, thin-walled bearings? How to avoid common mistakes?

Key factors in the selection process include load type, speed range, environmental conditions (such as temperature, humidity, or chemical exposure), and geometric limitations of the installation space. Why is load type so important? Because applications dominated by radial loads may require bearings with different designs, and thin-walled structures are prone to deformation under axial loads, requiring additional reinforcement. The speed range affects lubrication requirements—high-speed operation generates heat, requiring bearings with excellent heat dissipation and low-friction coatings. Common mistakes include ignoring environmental compatibility (such as humidity causing corrosion) or misjudging space constraints (such as insufficient wall thickness leading to installation cracks). The sales team at Ningbo Jinxin Bearing Technology Co., Ltd. excels at guiding customers through comprehensive evaluation by troubleshooting: they recommend working backward from the application scenario rather than simply looking at the product catalog—for example, stainless steel is recommended in humid environments; in compact spaces, the importance of pre-assembly testing is emphasized. This proactive consultation significantly reduces the risk of rework.

5. What are the best practices for the maintenance and life extension of large-bore, thin-walled bearings? How can professional support provide value?

Maintenance strategies should be primarily preventative, focusing on regular checks of lubrication conditions, monitoring vibration signals, and calibrating installation accuracy. Why is lubrication so crucial? Because the narrow clearances of thin-walled bearings easily accumulate contaminants, and failure often stems from grease degradation or the intrusion of external impurities, leading to accelerated wear. Extended lifespan depends on optimizing operating conditions: for example, avoiding overload operation or shock loads, which reduces material fatigue; simultaneously, a clean installation environment prevents particulate matter from embedding in the raceways. However, how do these practices translate into long-term benefits? Through systematic monitoring, customers can anticipate failure signs rather than resorting to reactive measures. The team at Ningbo Jinxin Bearing Technology Co., Ltd. frequently shares these insights during their services: they not only provide verbal guidance but also assist in developing maintenance plans—for example, recommending the use of specialized tools for disassembly to protect the thin-walled structure. For complex systems, their expertise helps customers integrate bearing health monitoring, thereby improving overall equipment lifespan.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch