In the field of mechanical engineering, thrust ball bearings are a key component widely used in various types of equipment. Their design and performance directly affect the efficiency and reliability of the overall system. Ningbo Jinxin emphasizes strict control in all production stages: after each process, they conduct independent inspections; the final product undergoes comprehensive testing according to customer requirements and recognized international standards to ensure the bearing's precision and durability.

Q1: What is the basic definition of a thrust ball bearing? How does it differ from other bearing types?

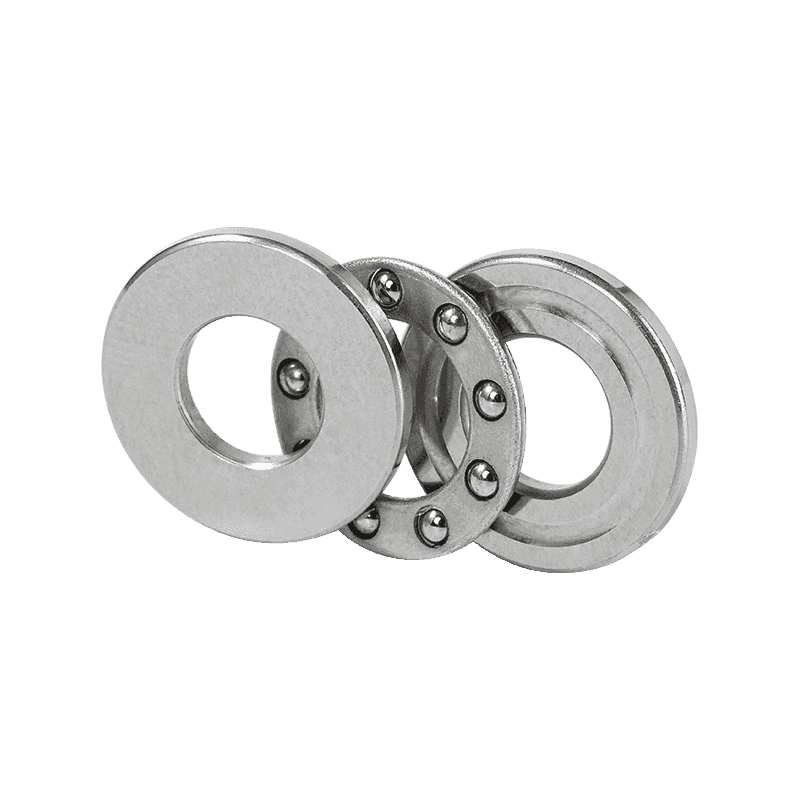

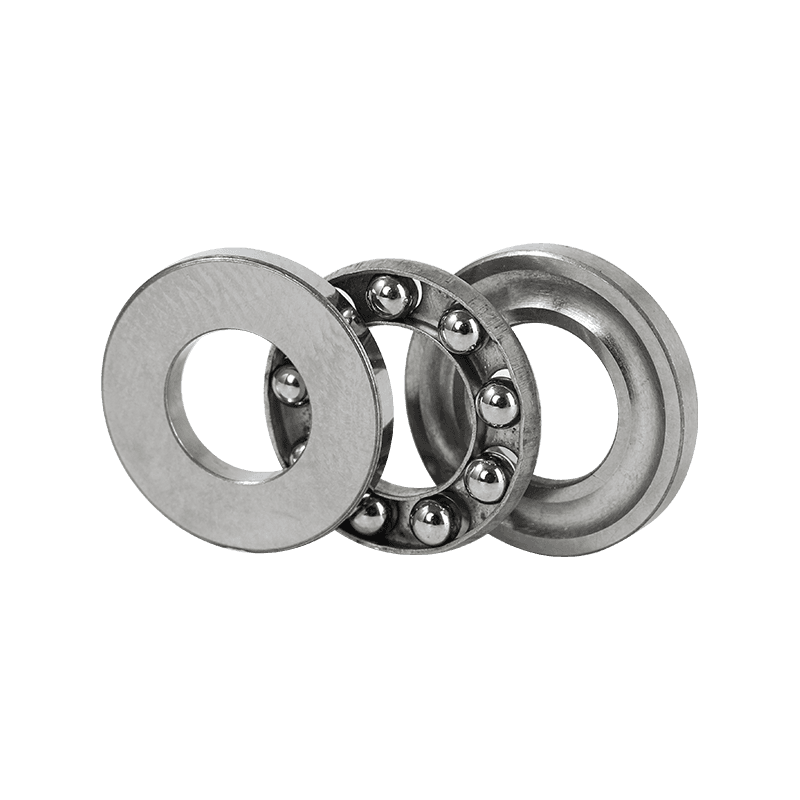

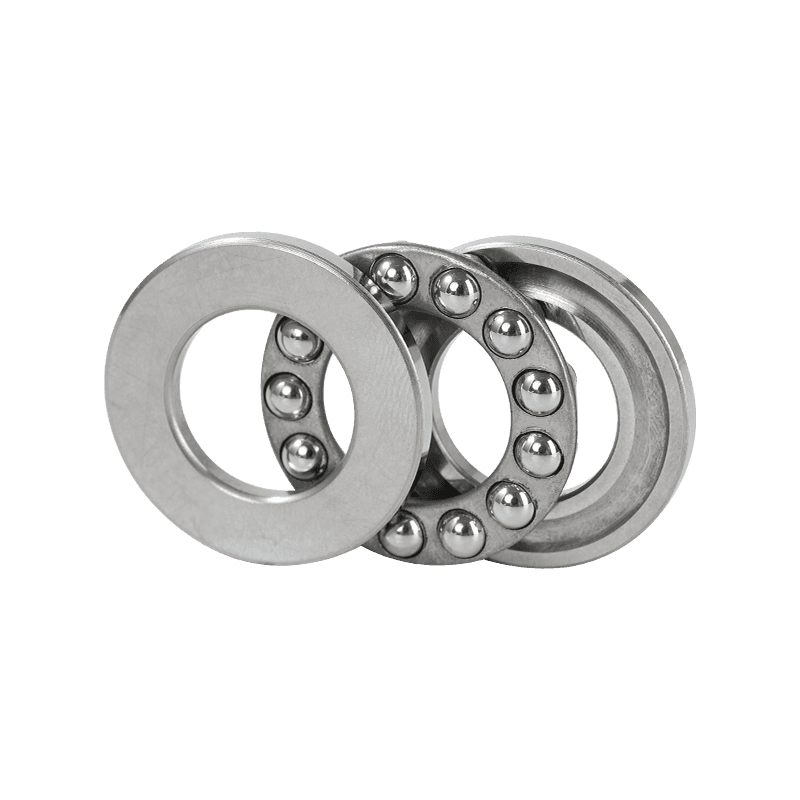

A: A thrust ball bearing is a rolling bearing specifically designed to withstand axial loads (i.e., forces applied along the axial direction). Unlike other bearings such as deep groove ball bearings, the core structure of a thrust ball bearing includes shaft washers, housing washers, and a set of precisely arranged balls. These components work together to efficiently convert axial force into rolling friction, thereby achieving smooth operation. During production, Ningbo Jinxin emphasizes the precise assembly of this structure—post-process inspections ensure that each component is correctly aligned, avoiding the risk of early failure due to misalignment.

Q2: How does the working principle of a thrust ball bearing demonstrate its high efficiency? In which scenarios does it play a key role?

A: The working principle of a thrust ball bearing is based on the rolling action of balls within the raceways of the washers. When an axial load is applied, the balls roll at the contact points, reducing sliding friction and thus improving transmission efficiency and energy utilization. This mechanism makes thrust ball bearings particularly suitable for high-speed or heavy-load environments, such as automotive transmissions, compressors, or industrial pump systems. In actual manufacturing, Ningbo Jinxin verifies the smoothness of the raceways through process inspections to ensure that the balls move without jamming, which directly enhances the bearing's response speed and stability in application.

Q3: What are the main advantages of thrust ball bearings? What are their potential limitations?

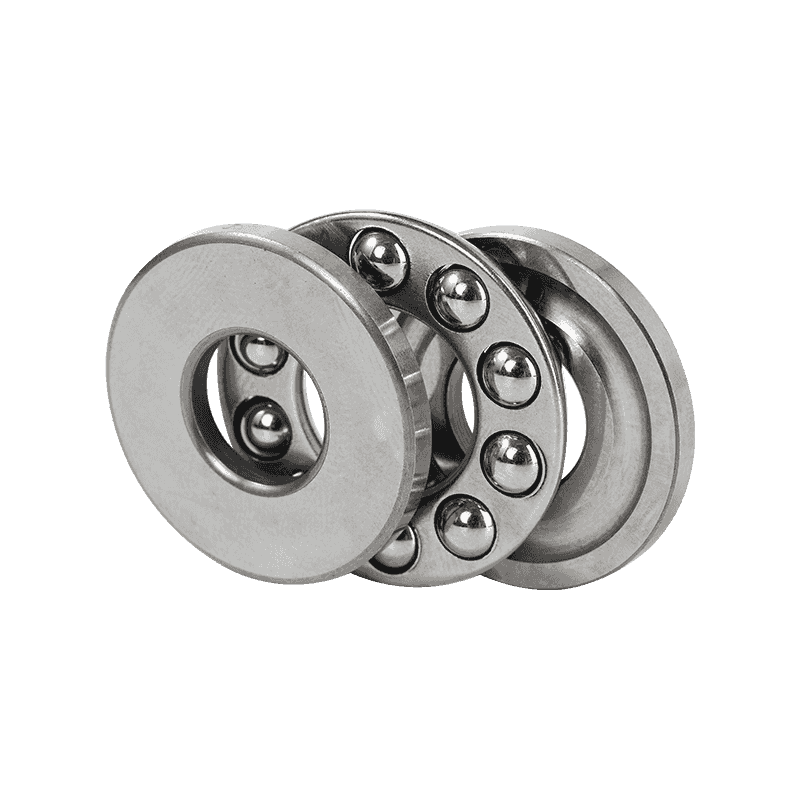

A: The advantages of thrust ball bearings lie in their compact structure, ease of installation, and shock resistance. They effectively isolate axial loads, reduce the burden on surrounding components, and adapt to varying operating conditions. However, potential limitations include a relatively weak ability to handle radial loads—excessive radial force may lead to bearing deformation or premature wear. To address this issue, Ningbo Jinxin conducts axial and radial tests simulating real-world operating conditions during the finished product inspection stage. It evaluates the load distribution uniformity according to international standards to ensure the bearing maintains reliable performance even under extreme conditions.

Q4: What are the maintenance cycles and common failure modes of thrust ball bearings? How can their service life be extended?

A: Thrust ball bearing maintenance typically involves regular lubrication, cleaning, and vibration monitoring. Common failure modes include overheating due to insufficient lubrication, wear caused by contaminant intrusion, or fatigue fracture due to raceway damage. The key to extending service life is selecting the appropriate lubricant and avoiding overload. Ningbo Jinxin's quality control system plays a crucial role here: process inspections include assessing the uniformity of lubricant application, while final inspection tests the seal integrity to prevent external impurities from penetrating, thereby maximizing the bearing's service life.

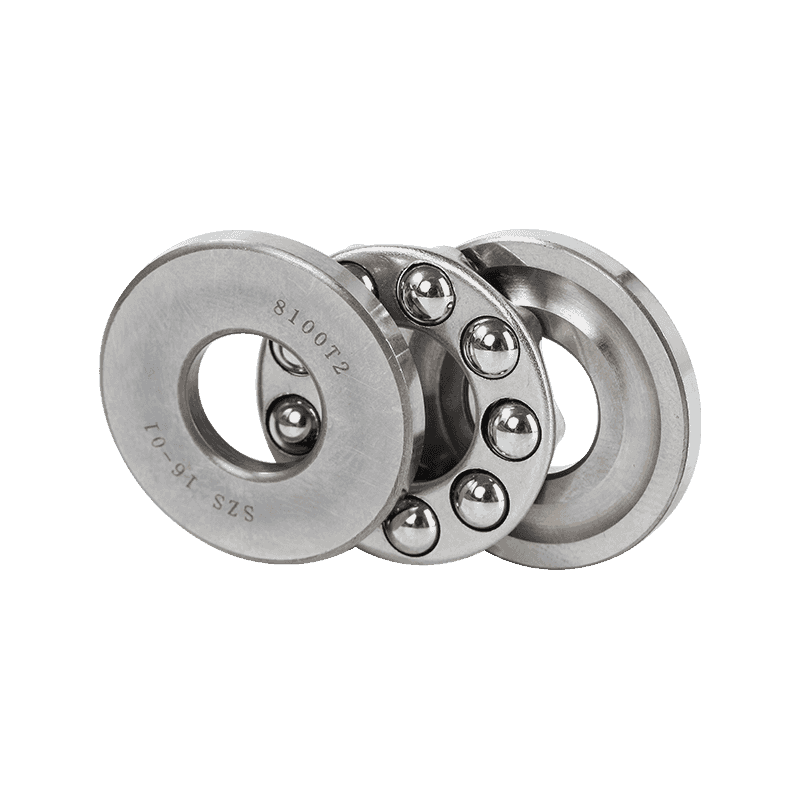

Q5: How is consistency and reliability ensured in the production of thrust ball bearings in terms of quality control?

A: Ensuring the consistency and reliability of thrust ball bearings must be maintained throughout the entire manufacturing chain. This includes raw material selection, heat treatment optimization, and dimensional tolerance control. Ningbo Jinxin's practice is as follows: After each process (such as turning, grinding, or assembly), targeted inspections are immediately implemented to promptly identify deviations. Final product inspection combines customer requirements with international standards (such as ISO), covering surface finish, hardness testing, and dynamic operation simulation. This layered quality control mechanism not only prevents batch defects but also provides predictable performance output for thrust ball bearings.

Q6: How does Ningbo Jinxin Bearing Technology Co., Ltd. integrate thrust ball bearing knowledge into its quality culture? What are the practical benefits for users?

A: Ningbo Jinxin directly translates its thrust ball bearing expertise into its production philosophy: through inter-process inspections and a final comprehensive inspection, they emphasize preventative quality rather than reactive correction. This culture ensures that every bearing meets axial load requirements, reducing unexpected failures in application. Users benefit from higher system uptime and cost-effectiveness because Ningbo Jinxin's thrust ball bearings achieve long-term stable service performance under rigorous quality control.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch