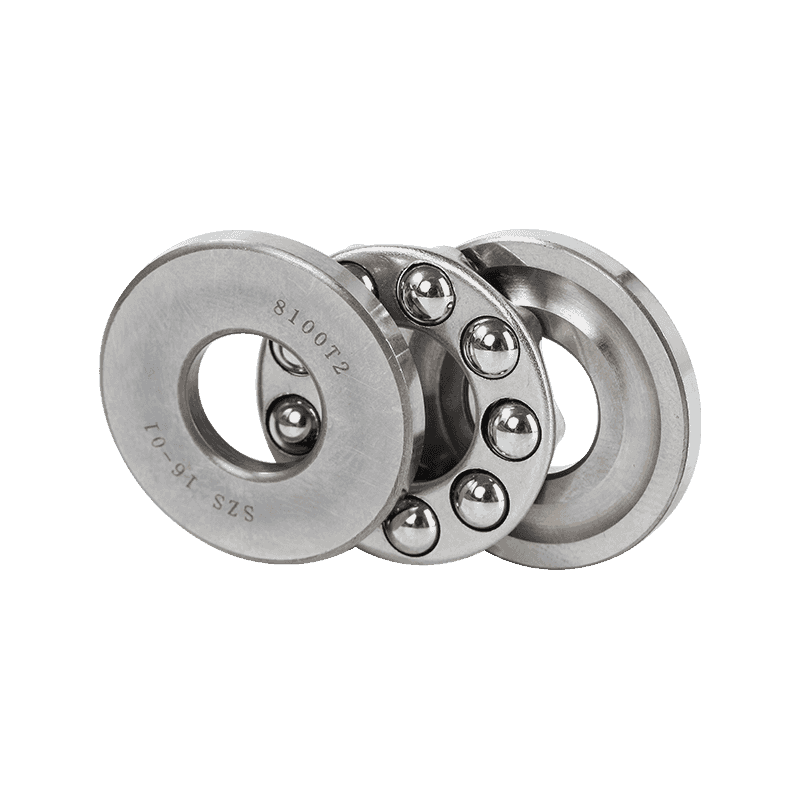

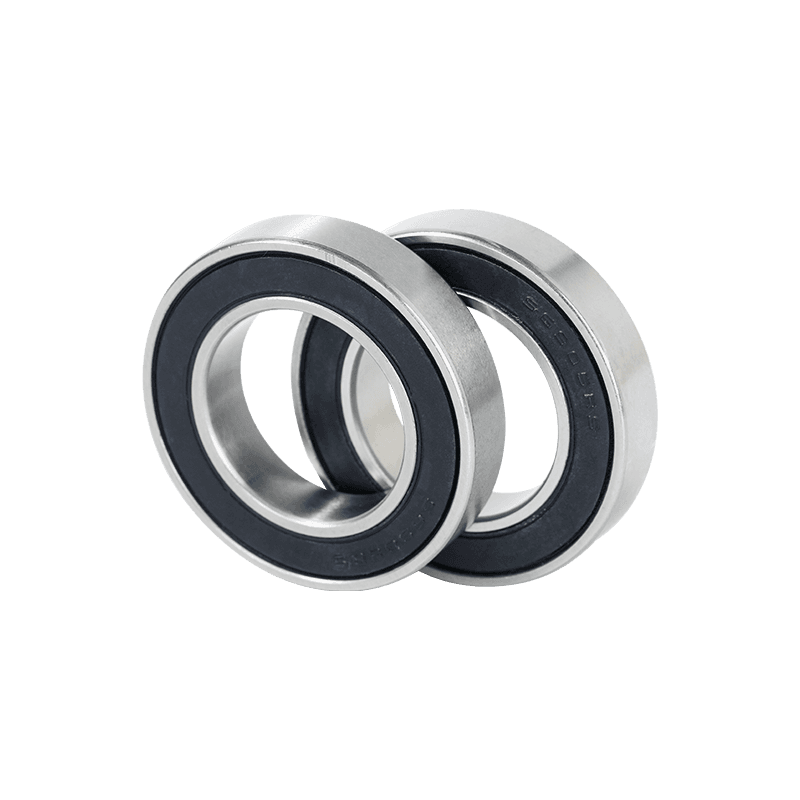

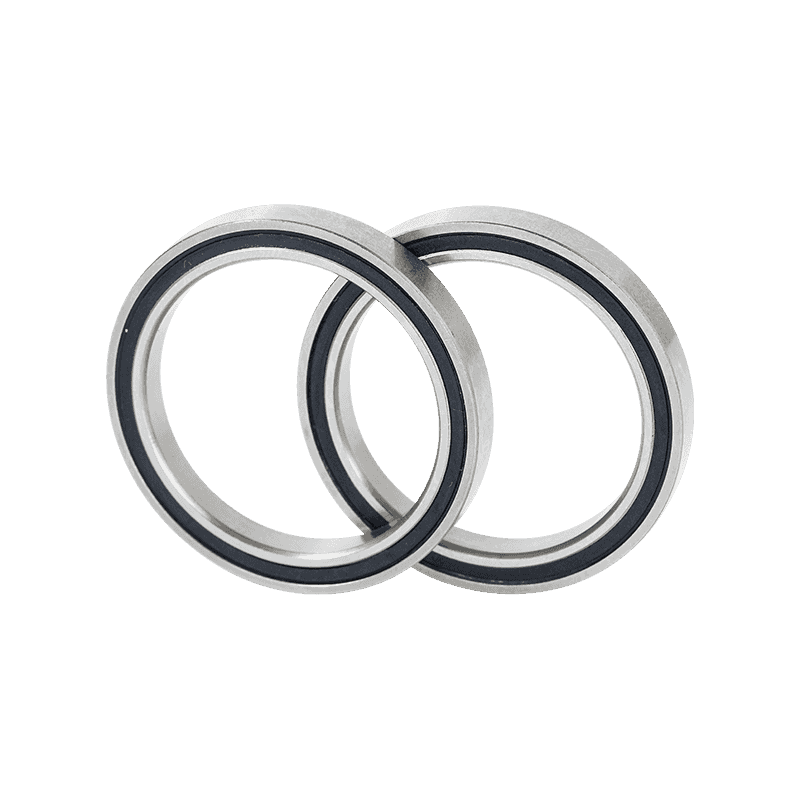

In the bearing manufacturing industry, stainless steel ball bearings, with their unique material properties and wide applicability, have become key components in many industries. As a company deeply rooted in bearing technology for many years, Ningbo Jinxin Bearing Technology Co., Ltd. leverages its professional manufacturing capabilities to continuously integrate cutting-edge knowledge into product development.

Question 1: What are the core material characteristics of stainless steel ball bearings?

Answer:

•The material basis originates from specific grades of stainless steel alloys. These alloys, through precise proportioning, endow the bearings with excellent corrosion resistance, enabling them to operate stably for extended periods in humid or chemical environments.

•The alloy structure contains a high proportion of chromium, forming a passive protective layer that effectively resists oxidation and acid corrosion, thereby extending the overall lifespan of the bearing.

•The application of heat treatment processes further optimizes the hardness and toughness of the material, ensuring that the balls maintain geometric accuracy during high-speed rotation, preventing deformation or failure.

•Ningbo Jinxin Bearing Technology Co., Ltd. strictly adheres to industry standards in material selection, optimizing alloy composition through internal R&D to adapt to different operating conditions and improve product reliability and consistency.

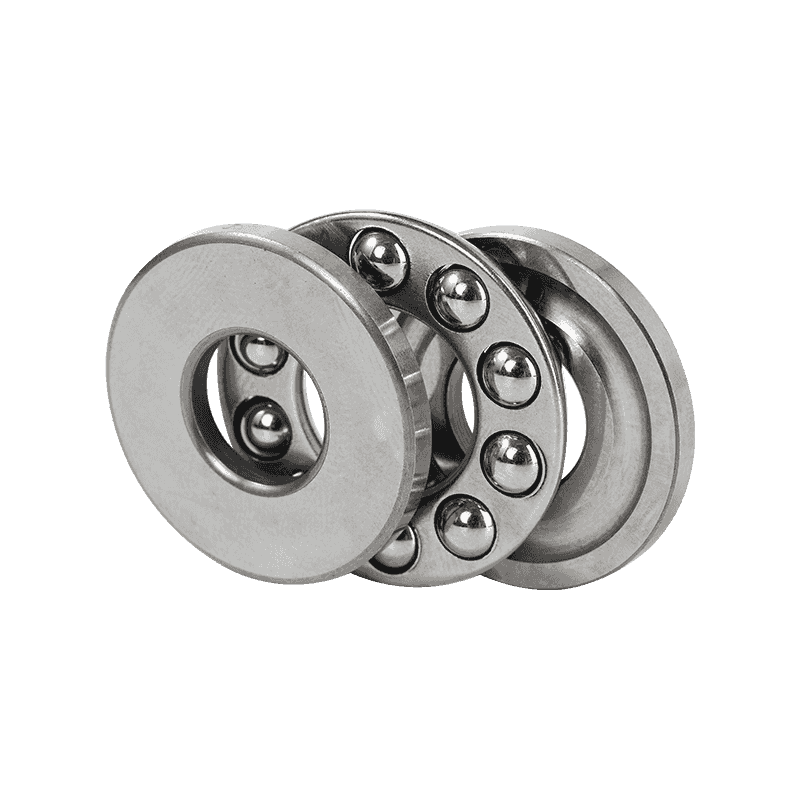

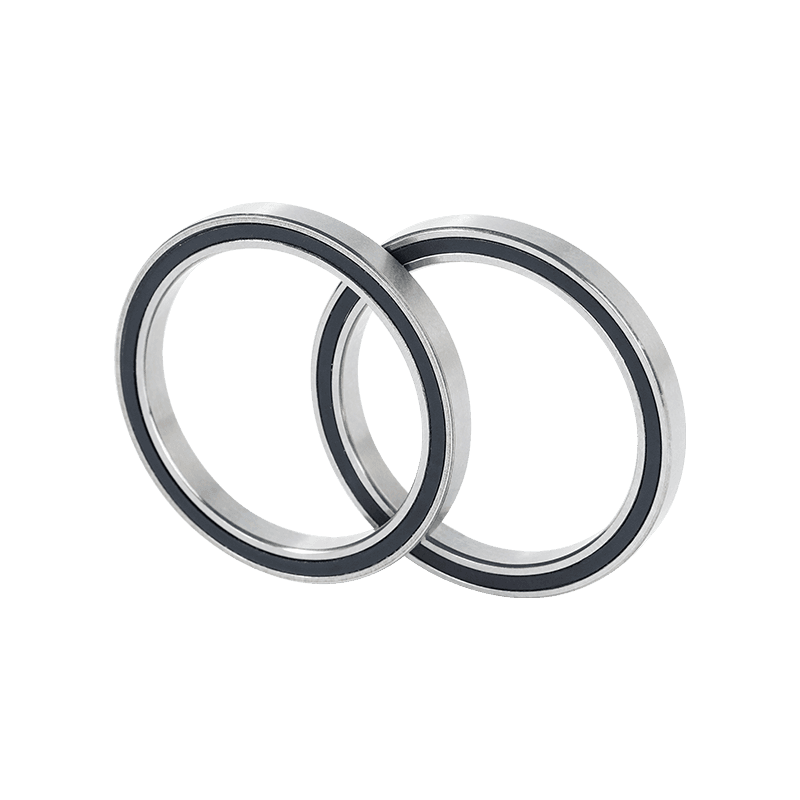

Question 2: What are the significant advantages of stainless steel ball bearings compared to traditional bearings?

Answer:

•Its outstanding environmental adaptability makes it a preferred choice in food processing, medical equipment, and marine engineering, where these fields require components that are non-polluting, easy to clean, and resistant to bio-corrosion.

•The high-strength design provides excellent load-bearing capacity, maintaining smooth operation even under extreme temperature or vibration conditions, reducing maintenance frequency and operating costs.

•The low coefficient of friction is achieved through surface finishing, reducing energy consumption and noise, making it suitable for precision instruments or quiet environments, such as laboratory equipment or household appliances.

•Ningbo Jinxin Bearing Technology Co., Ltd. leverages these advantages, integrating advanced technologies into the manufacturing process to ensure that each bearing unit delivers durable performance, meeting customers' demands for efficient and environmentally friendly solutions.

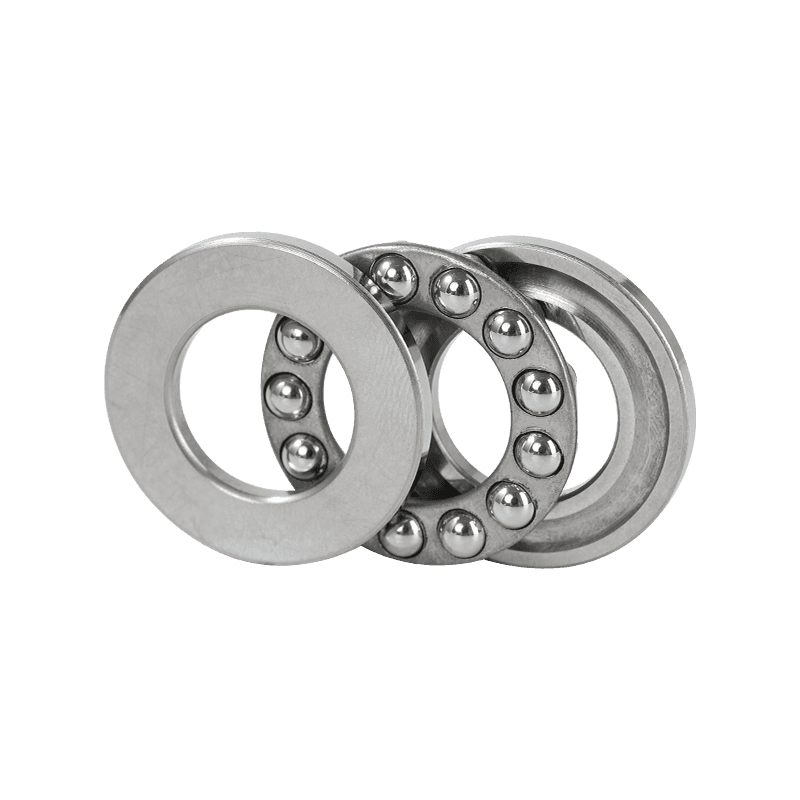

Question 3: What are the common industrial applications of stainless steel ball bearings?

Answer:

•Widely deployed in the food and beverage industry as transmission components in conveyor belts, mixers, or filling equipment, thanks to their non-reactive surfaces, preventing bacterial growth and meeting hygiene standards.

•In the medical field, they are used in surgical instruments, imaging equipment, or diagnostic tools, providing high-precision rotational support to ensure operational safety and patient comfort.

•Outdoor and sports equipment, such as bicycle wheels or marine propulsion systems, utilizes the weather resistance of bearings to protect against rain and salt spray corrosion, extending the overall lifespan of the device.

•Ningbo Jinxin Bearing Technology Co., Ltd. optimizes bearing designs for these applications through customized services, such as adjusting sealing structures or lubrication schemes to adapt to specific industry challenges, helping users improve equipment efficiency and sustainability.

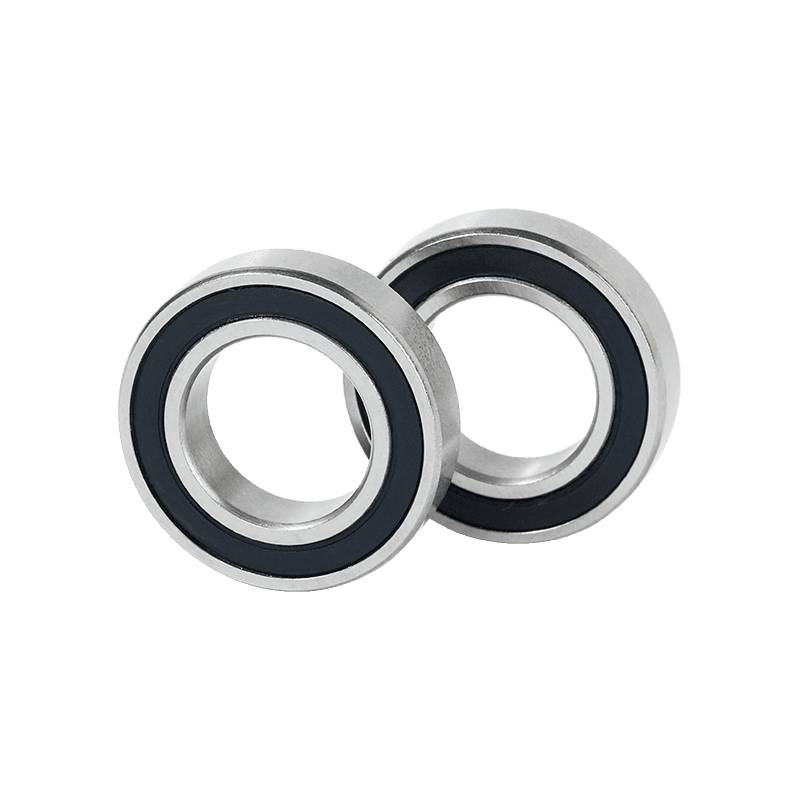

Question 4: How do manufacturers ensure the quality and performance optimization of stainless steel ball bearings?

Answer:

•Implementing rigorous manufacturing processes, including precision grinding and polishing stages, to eliminate microscopic defects, ensure smooth contact between the balls and raceways, and reduce wear and energy loss.

•The quality control system encompasses non-destructive testing methods, such as magnetic particle testing or ultrasonic scanning, to identify internal cracks or impurities, ensuring that each product reaches peak performance before leaving the factory.

•Surface treatment technologies, such as electropolishing or coating applications, enhance anti-adhesion properties, preventing foreign matter accumulation, thereby maintaining low noise and high efficiency under dynamic loads.

•Ningbo Jinxin Bearing Technology Co., Ltd. integrates this knowledge and continuously improves its processes through its own laboratories and testing capabilities, emphasizing preventive maintenance design to ensure that bearings maintain their initial accuracy during long-term use and reduce the risk of overall system failure.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch